rocketgeek101

Well-Known Member

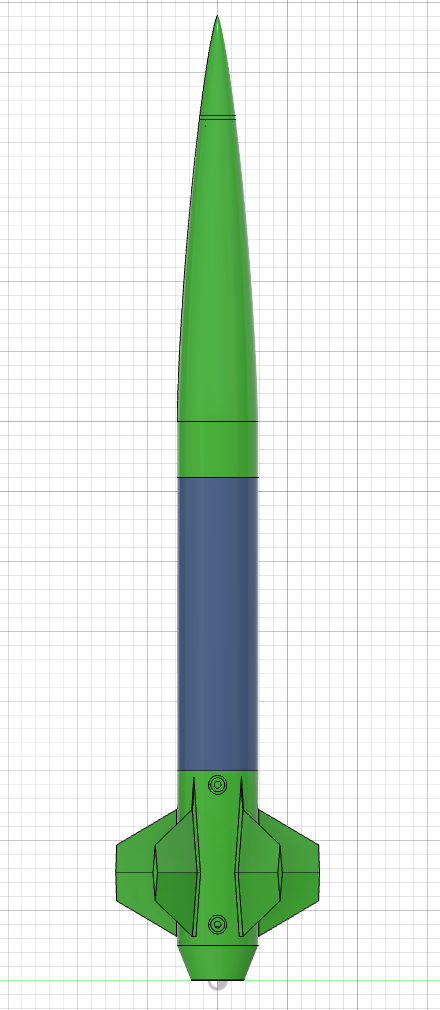

Love the design! Very MAC Performance Blackfly-ish. Any chance you'd be willing to share the STL files?Almost maxing out the Z on my 300mm Voron. This will be a 54mm airframe, 5:1 Von Karman nose cone, and 29mm power. The nose cone tip was printed separately to keep the height within range of the printer, and so that I can add ballast if necessary.

I'm working the CAD on a 38mm version now.

The CAD:

And the prototype dry assembly: