lots of Youtube videos:how in the heck do you use a bandsaw to make something circular without binding up the blade?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

What did you do rocket wise today?

- Thread starter BeerorKid

- Start date

Help Support The Rocketry Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

- Joined

- Jan 20, 2011

- Messages

- 6,388

- Reaction score

- 2,067

- Cut and added some more vinyl to my Solar Sailer 2.6 rocket.

- Cut some roll pattern vinyl for the USR HiTest 2224 (or something like that) which I call "24mm Madness"

- Cut some more vinyl for my OD Mojave Mortar which is 6' tall and used a 54mm ACME fin can.

- Finished building an Eggtimer Quark. Tested. Works fine. I still can not figure out how to CAD up a mount for it that lets me take it from one diameter rocket to another where each of the hosts has its own outside switch. Especially BT55 to say BT70 size rockets. There must be a design that lets one expand the sled in both X and Y to fit the bay of that rocket. And that makes it the doddle to hook up a switch for arming in each rocket. I have never ever dedicated any electronics to one rocket.

- Added the first coat of gloss white to a Nova Rocketry 44MK13. Krylon Fusion. Crap. Never buy that again. Primer and Paint? REALLY low solids. I'll sand it down after a few days drying

- Stared at my SS Package knowing that due to my spouses health, there will be no Christmas this year and wondering? Who'll ever know? I guess ... I will. How stupidly old fashion

How in the heck do you use a bandsaw to make something circular without binding up the blade?

You could with a jig...

The jig I was talking about (and plan to make one day is as simple as a square piece of wood with a dowel or nail sticking our of it. Clamp the base to the bandsaw with the dowel/pin half distance that you want the circle cut and add a square piece with a hole in the center, rotate.Bandsaws have blades of varying width, use a narrow blade for tighter turns/circles and the wider blades for straight/resaw cuts, each blade width is a compromise between manueverability and stiffness....then there are the different tooth patterns/designs.

I laminated some more foam board to the Port-O-Potty base and then cut the base into a circle. I painted the Christmas tree rocket. Red, of course. I'll finish it tomorrow night. I'm taking 10 cats into Vegas to get fixed for the cat rescue during the day tomorrow. The Rockwell Jaw Stand I ordered arrived today. I'll move my rail to it be fore I need a pad. Now my rail is bolted to a PVC spider. Big and bulky.

![20221213_162014[1662].jpg 20221213_162014[1662].jpg](https://cdn.imagearchive.com/rocketryforum/data/attachments/467/467727-3f9a181234ba042b08f93c329725e961.jpg)

![20221213_224035[1669].jpg 20221213_224035[1669].jpg](https://cdn.imagearchive.com/rocketryforum/data/attachments/467/467728-659e74f384daa6bd7f45262603f7ec4f.jpg)

![20221213_224044[1664].jpg 20221213_224044[1664].jpg](https://cdn.imagearchive.com/rocketryforum/data/attachments/467/467729-2aa0d066c2327688a578900623ec0d42.jpg)

![20221213_224105[1665].jpg 20221213_224105[1665].jpg](https://cdn.imagearchive.com/rocketryforum/data/attachments/467/467730-af2f3e168125d491017351b0f2b2d0cf.jpg)

![20221213_162014[1662].jpg 20221213_162014[1662].jpg](https://cdn.imagearchive.com/rocketryforum/data/attachments/467/467727-3f9a181234ba042b08f93c329725e961.jpg)

![20221213_224035[1669].jpg 20221213_224035[1669].jpg](https://cdn.imagearchive.com/rocketryforum/data/attachments/467/467728-659e74f384daa6bd7f45262603f7ec4f.jpg)

![20221213_224044[1664].jpg 20221213_224044[1664].jpg](https://cdn.imagearchive.com/rocketryforum/data/attachments/467/467729-2aa0d066c2327688a578900623ec0d42.jpg)

![20221213_224105[1665].jpg 20221213_224105[1665].jpg](https://cdn.imagearchive.com/rocketryforum/data/attachments/467/467730-af2f3e168125d491017351b0f2b2d0cf.jpg)

Just uploaded some videos from the last flying day near Cologne / germany

TLP Hellfire:

Own design MIM-23 Hawk:

Two Mercury REdstones: Estes and an own design:

We had great fun

TLP Hellfire:

Own design MIM-23 Hawk:

Two Mercury REdstones: Estes and an own design:

We had great fun

GrouchoDuke

Well-Known Member

- Joined

- Oct 18, 2016

- Messages

- 1,693

- Reaction score

- 1,537

Hunted for upcoming launches within a not-too-horrible distance and pretty good waivers to fly things in the next few months. Wide open spaces are tough to find...missing the desert a bit.

Related: Considered moving to Seymour or Wichita.

Related: Considered moving to Seymour or Wichita.

lakeroadster

When in doubt... build hell-for-stout!

Necessity is the mother of invention.twice the big balsa fins have cracked/broken.

Have I mentioned today how much I hate cheap, primitive, weak balsa? I'll never build anything with it.

Balsa Plywood, 2 ply or 3 ply. You can make your own.

Or, paper the balsa using wood glue.

Now THAT'S how you make a sensible Christmas tree rocket!I laminated some more foam board to the Port-O-Potty base and then cut the base into a circle. I painted the Christmas tree rocket. Red, of course. I'll finish it tomorrow night. I'm taking 10 cats into Vegas to get fixed for the cat rescue during the day tomorrow. The Rockwell Jaw Stand I ordered arrived today. I'll move my rail to it be fore I need a pad. Now my rail is bolted to a PVC spider. Big and bulky.

View attachment 550860View attachment 550862

- Joined

- May 29, 2019

- Messages

- 1,234

- Reaction score

- 993

Kilz is is not enamel is it? Is it compatible with most enamel rattle cans?

Not sure *exactly* what it is, other than an alkyd resin base, and they seem to want to protect its stain-blocking characteristics. It is Oil-based, and the can states it is compatible with alkyd, oil, and water-based topcoats. I've used the brush-painted version of the same product and it works very well, and have had no incompatibility issues with that.

I will let you know if I have any issues with the spray version when my color paint arrives. So far, small test spots look like painting over smooth sanded CWF.

SDS for this

DATA SHEET for this

Edited---Or I'll post pictures after painting.

Last edited:

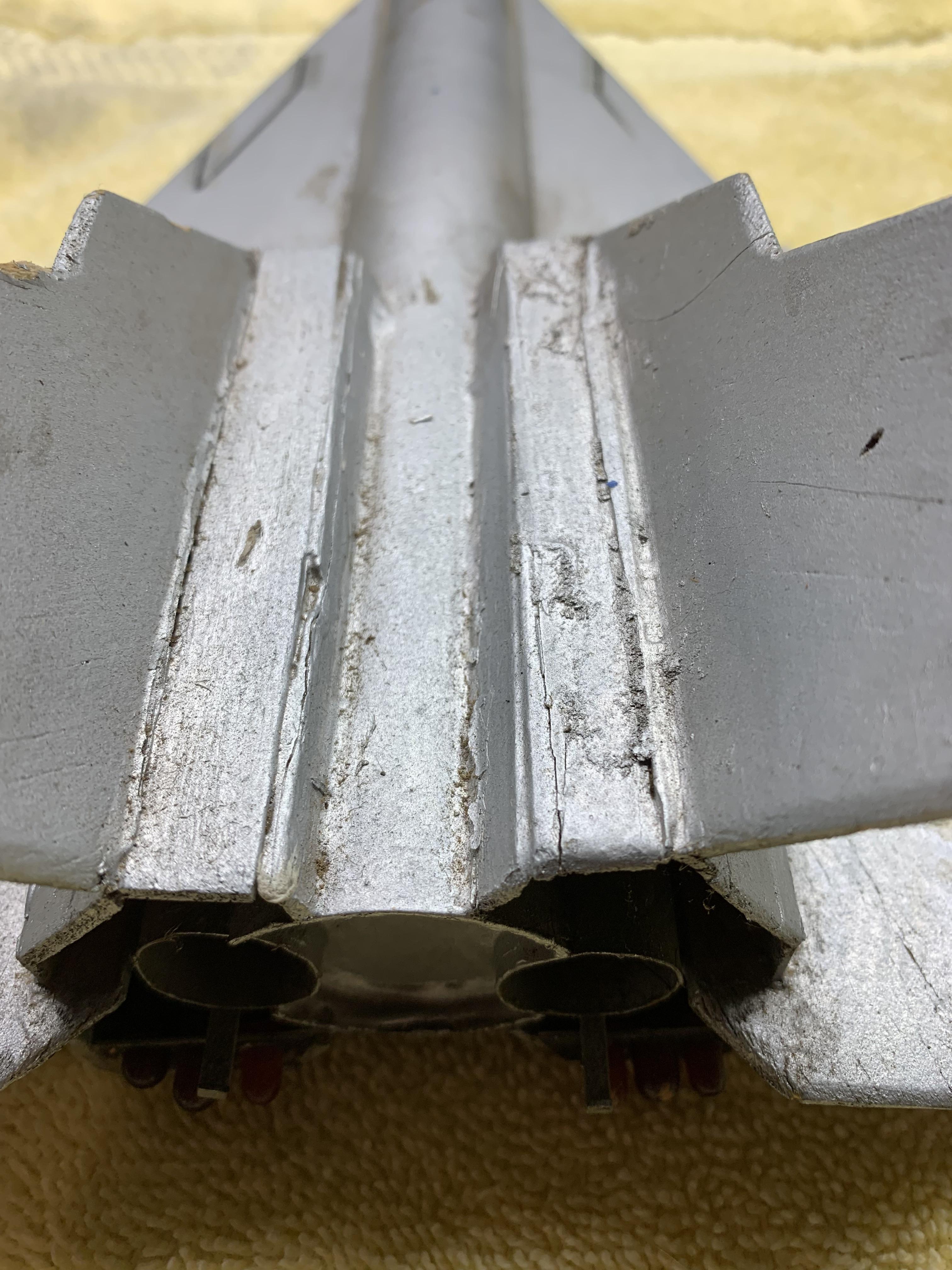

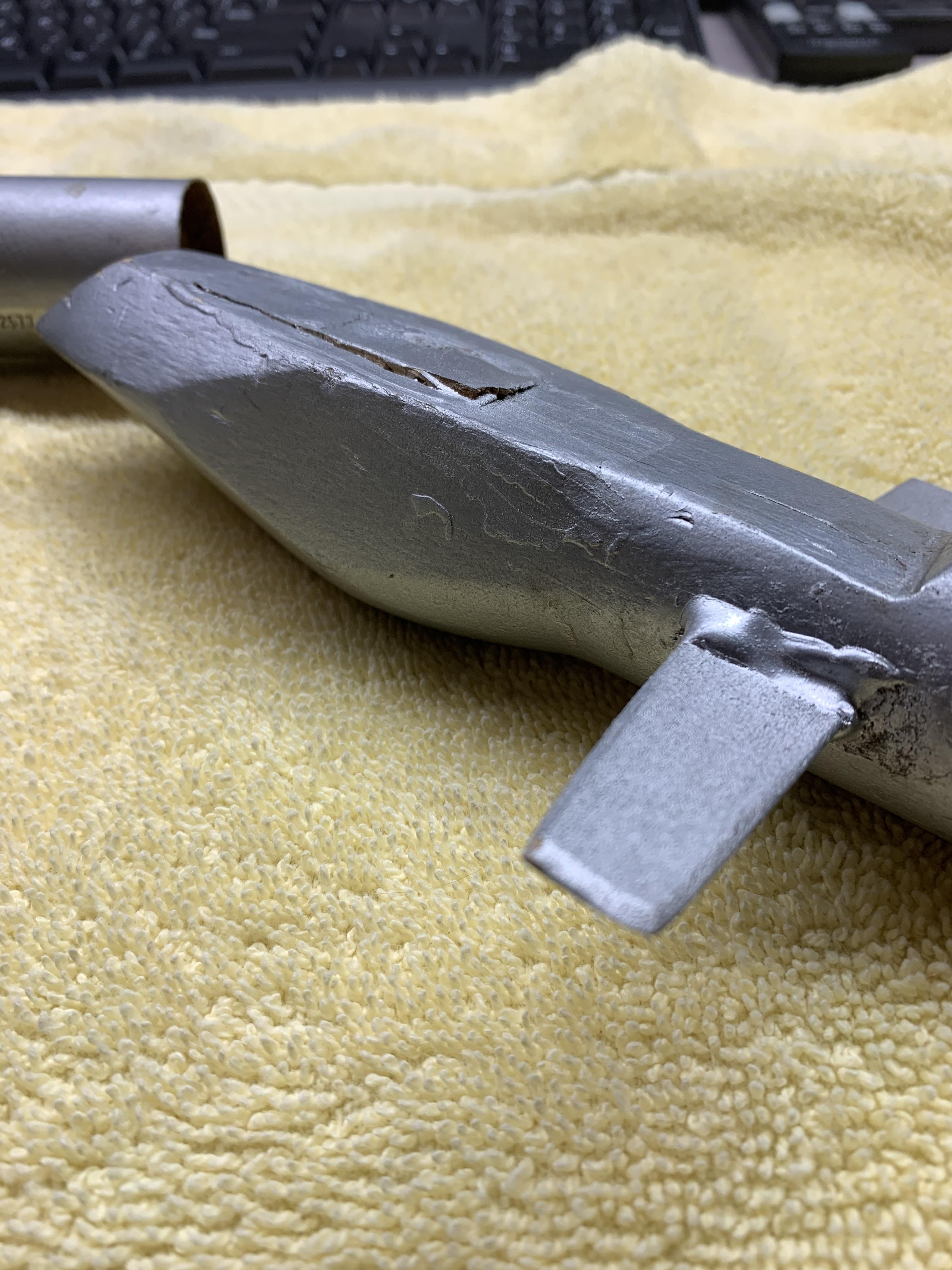

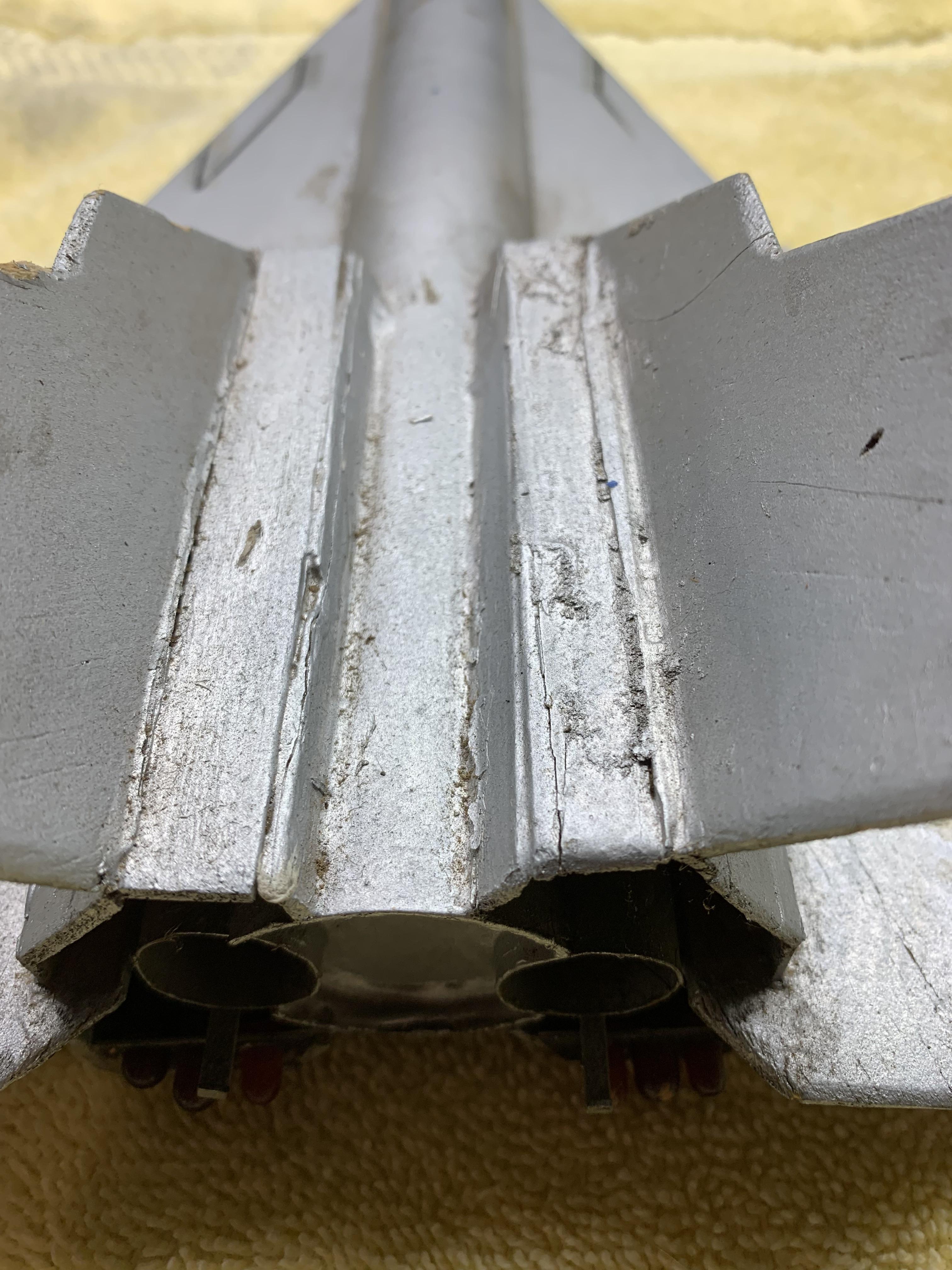

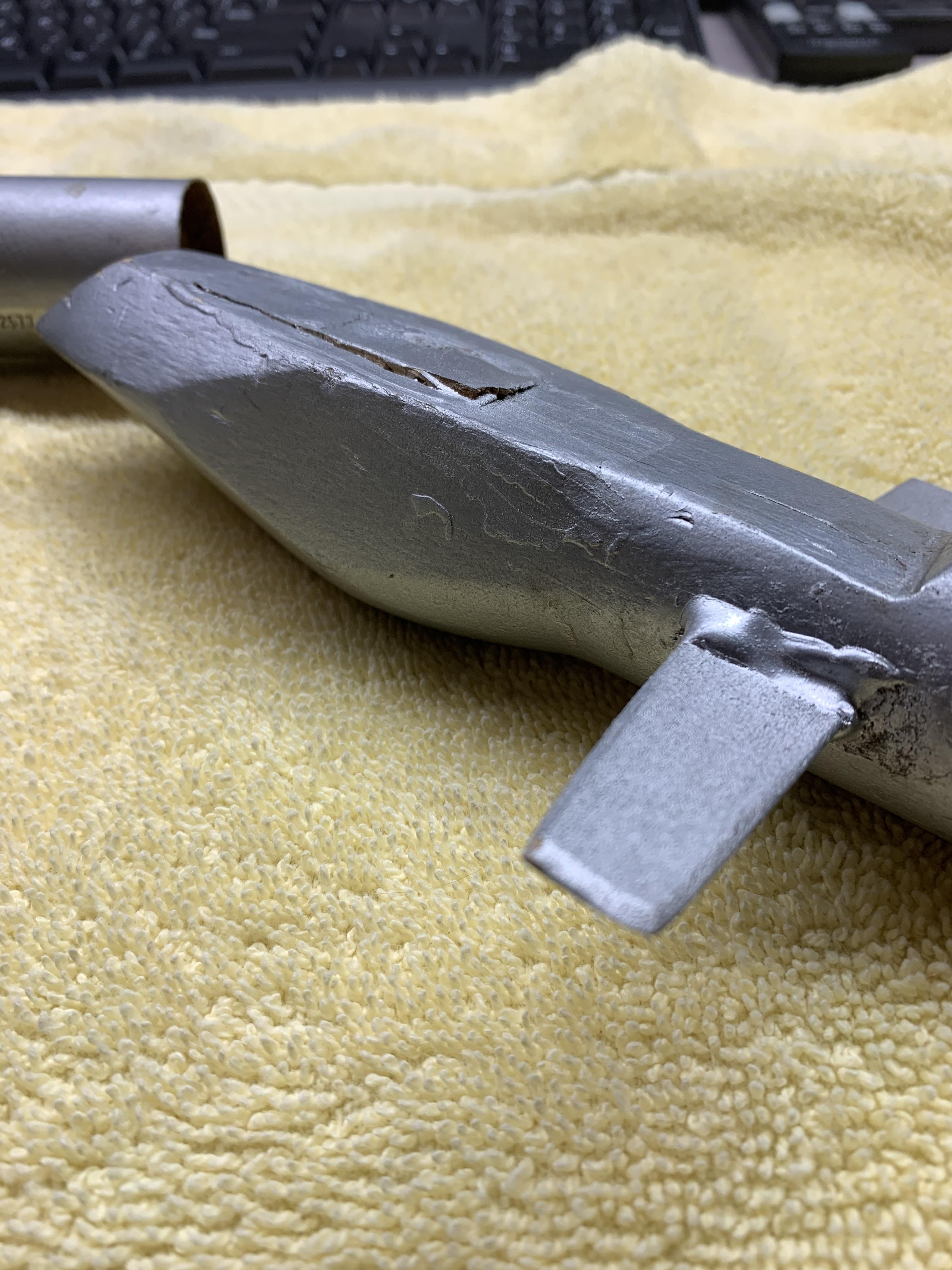

I sanded more on the POS Mig-31, and another balsa butt joint cracked  you look at this stuff and it breaks..I'm glad this is the last model made from this cheap/inferior/low strength material that I'll have to restore. There's still a chance I'll toss it in the dumpster.

you look at this stuff and it breaks..I'm glad this is the last model made from this cheap/inferior/low strength material that I'll have to restore. There's still a chance I'll toss it in the dumpster.

more sanding on the Mig-31, but I don't last long before all enthusiasm dies.

lakeroadster

When in doubt... build hell-for-stout!

Post up some photo's...more sanding on the Mig-31, but I don't last long before all enthusiasm dies.

40 year old and poorly constructed.Post up some photo's...

initial sanding done

lakeroadster

When in doubt... build hell-for-stout!

40 year old and poorly constructed.

initial sanding done

That's awesome. What's the backstory?

The guy posted on here that he had some old rockets that he wanted to give away. So we went about 30 miles to his house in Charlotte. He was 85 and with a walker, so was I, even though I'm 66, but physically 90. He had some photos of when he worked on the Corporal rocket program w/ training completion certificates, but all 7 rockets were built around 1979-1983 including a 4 ft Corporal and a 6 ft Corporal, and both of them are in good shape. This one was the worst of them. Now that the initial sanding is done, I'll use the DAP spackling compound and likely spend many hours going over it to get it ready for primer. I'm mainly doing this so that I can email him back pictures of my restoration work. He also wants to see videos of them launching again. This also gives me something to try and coax me out of this bed that I spend 18-22 hours in everyday.That's awesome. What's the backstory?

lakeroadster

When in doubt... build hell-for-stout!

Cool story Marty. Good karma coming your way for all the effort you're putting into this.The guy posted on here that he had some old rockets that he wanted to give away. So we went about 30 miles to his house in Charlotte. He was 85 and with a walker, so was I, even though I'm 66, but physically 90. He had some photos of when he worked on the Corporal rocket program w/ training completion certificates, but all 7 rockets were built around 1979-1983 including a 4 ft Corporal and a 6 ft Corporal, and both of them are in good shape. This one was the worst of them. Now that the initial sanding is done, I'll use the DAP spackling compound and likely spend many hours going over it to get it ready for primer. I'm mainly doing this so that I can email him back pictures of my restoration work. He also wants to see videos of them launching again. This also gives me something to try and coax me out of this bed that I spend 18-22 hours in everyday.

Should I be discharging lipos?Actually, it's what I've been doing since Wednesday of last week...

Was going to attempt my Level 3 Cert on the 3rd, but the cloud ceiling never lifted like the meteorologists predicted. So it was charge Lipos, assemble avionics, load charges, pack the truck, go to the launch site, stare at the sky & swear, go home, unpack the truck, dump charges, disassemble stuff & discharge/store LiPos... just now

finishing.

View attachment 549364

Updated the CAD file of some parts I've designed for a friend, since he embiggened the motor mount he's using from 29 to 38. Added a few more drawings to the consolidated burn sheets I'm building. Still have a few more parts to draw before sending 1/4" and 1/8" sheets off to @Chad / Oak Cliff Laser to burn. Maybe I'll finally finish this weekend, but more likely I'll discover another few parts I need and add another week to the timeline.

As I recall you're hunting for another record? If what you're after can be accomplished in 32k, we'd love to see you do it in Seymour on the last weekend of next month. Hat tip to Kloudbusters though: they fly every month of the year - whereas we only fly at Seymour four or five times due to summer heat and hunting leases - and they have 50k, whereas we only have 32k due to the nearby highway. Either way, good luck finding those ceilings!Hunted for upcoming launches within a not-too-horrible distance and pretty good waivers to fly things in the next few months. Wide open spaces are tough to find...missing the desert a bit.

Related: Considered moving to Seymour or Wichita.

embiggened

Nicely enverbed.

Nicely enverbed.

“It’s a perfectly cromulent word.”

“It’s a perfectly cromulent word.”

In Springfield, anyway.

sounds like the "Word Association" threadNicely enverbed.

Precisely!“It’s a perfectly cromulent word.”

sounds like the "Word Association" thread

A Simpsons Word Association League Football Boot Lace Aglet Brass Monkey Thread.

Similar threads

- Replies

- 158

- Views

- 6K

- Replies

- 5

- Views

- 319

- Replies

- 22

- Views

- 2K

- Replies

- 1

- Views

- 1K