ECayemberg

Well-Known Member

- Joined

- Jan 21, 2009

- Messages

- 2,877

- Reaction score

- 849

Now that I have everybody fooled into thinking that I only build low and slow behemoths, let's begin a departure from that concept and venture into the speed realm. I'm guilty of liking big rockets, low and slow, cardboard and plastic...I really do! BUT I also like testing the melting point of composites and ablatives. After a few years absence from the stellar Rocket Pasture in Argonia, heaven willing I'm eager to make a return in 2017! With a lot of open air above Kansas, I like to test out the skies a bit while there. Here's one of the projects for Airfest this year!

A few sources of inspiration.

1. Loki 54/4000 hardware. I've always liked the Kosdon, then AMW 54/2550 motors. I've always admired the Kosdon 2.1(54)-3300 hardware. When Loki turned the 54/4000 hardware loose, I jumped on the first run. When a 54mm M was certified, I had to have one. Now I gotta fly the darn thing!

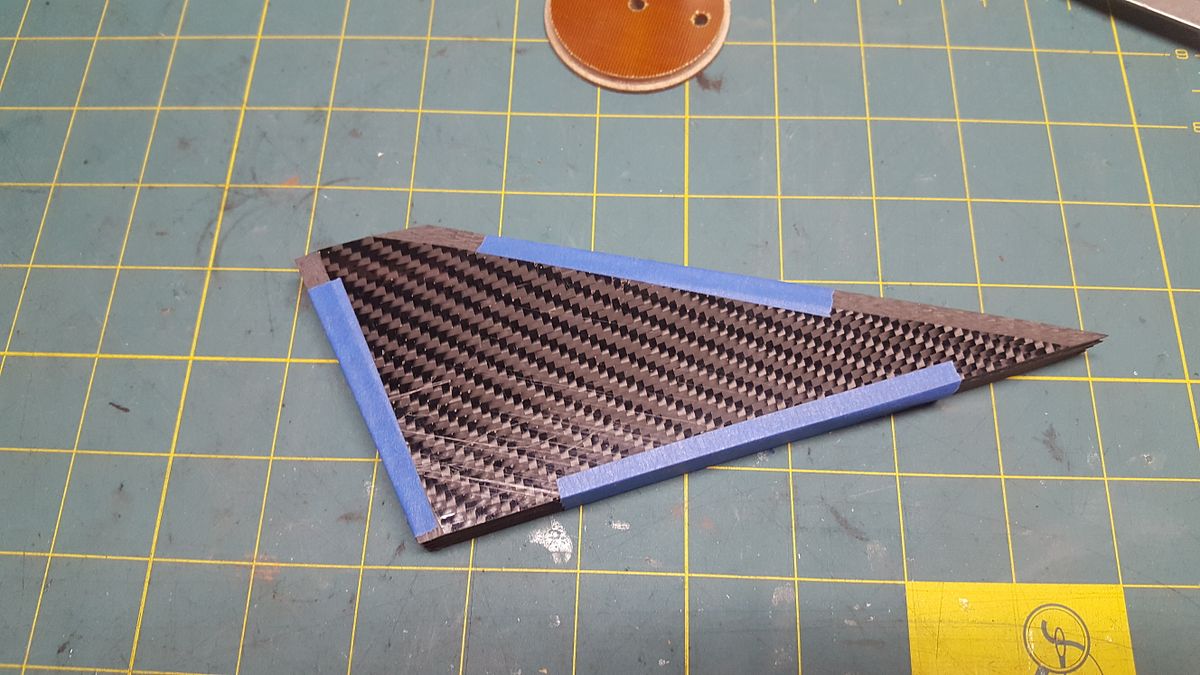

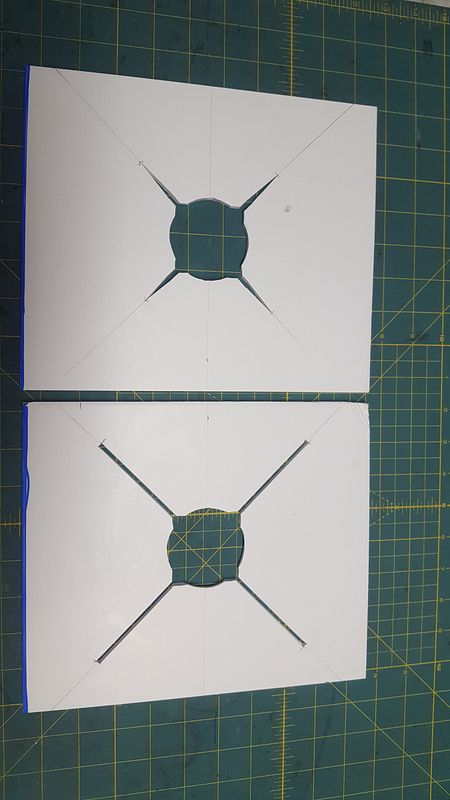

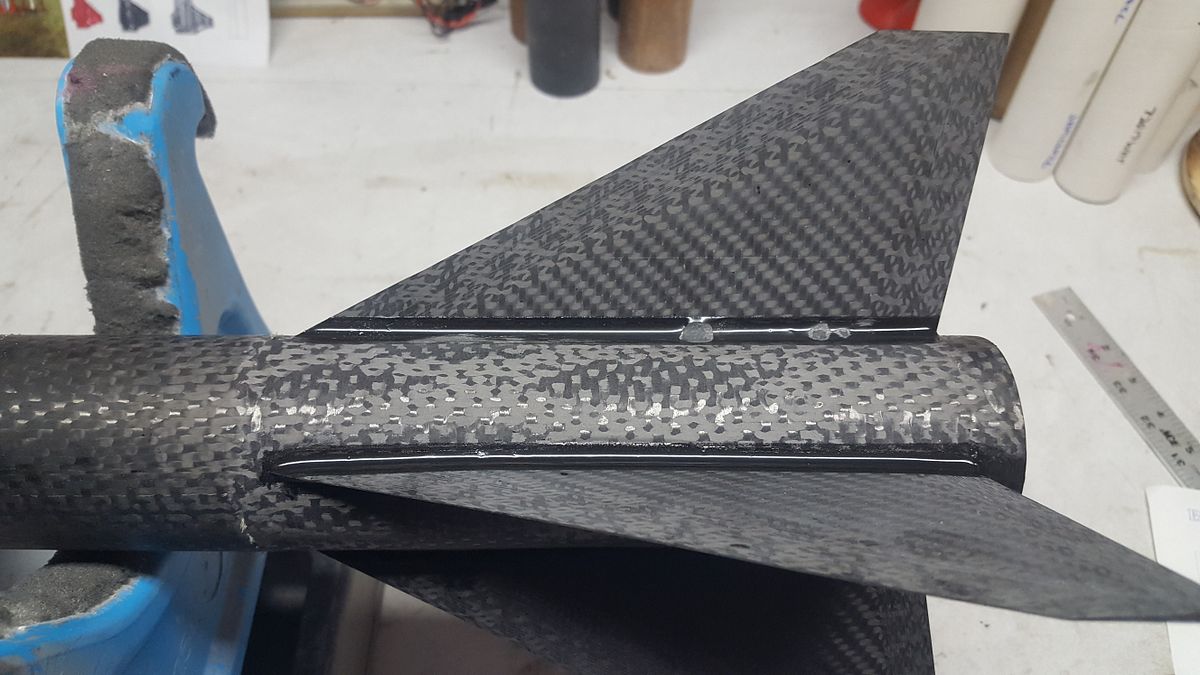

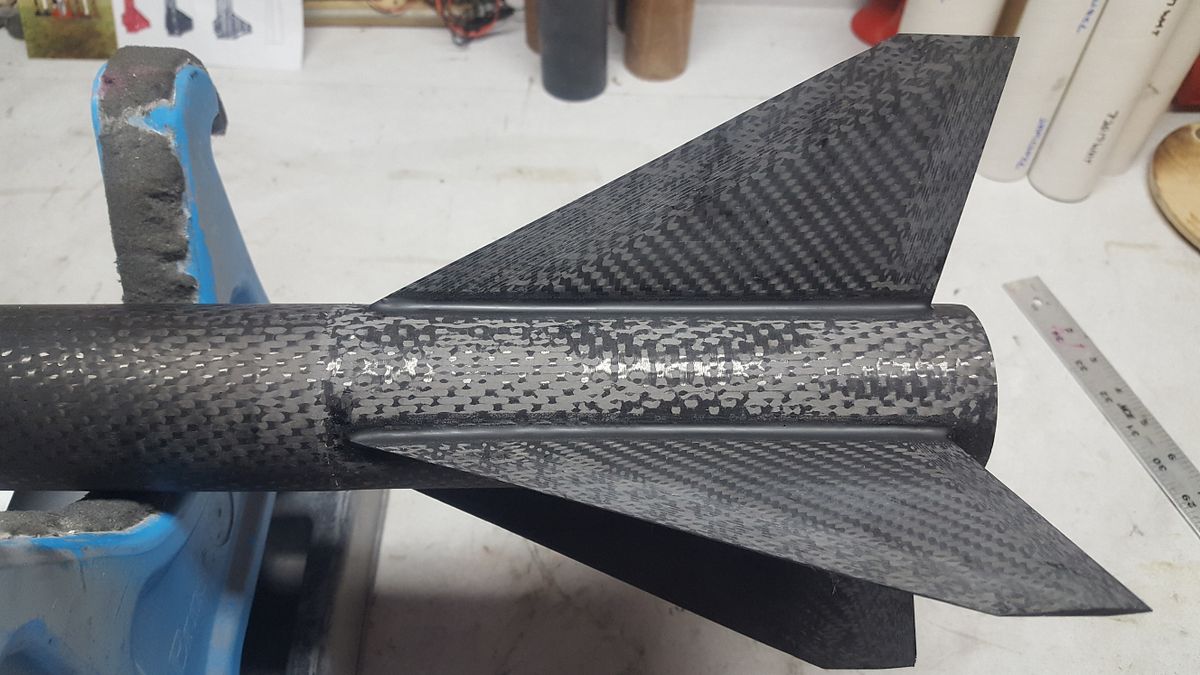

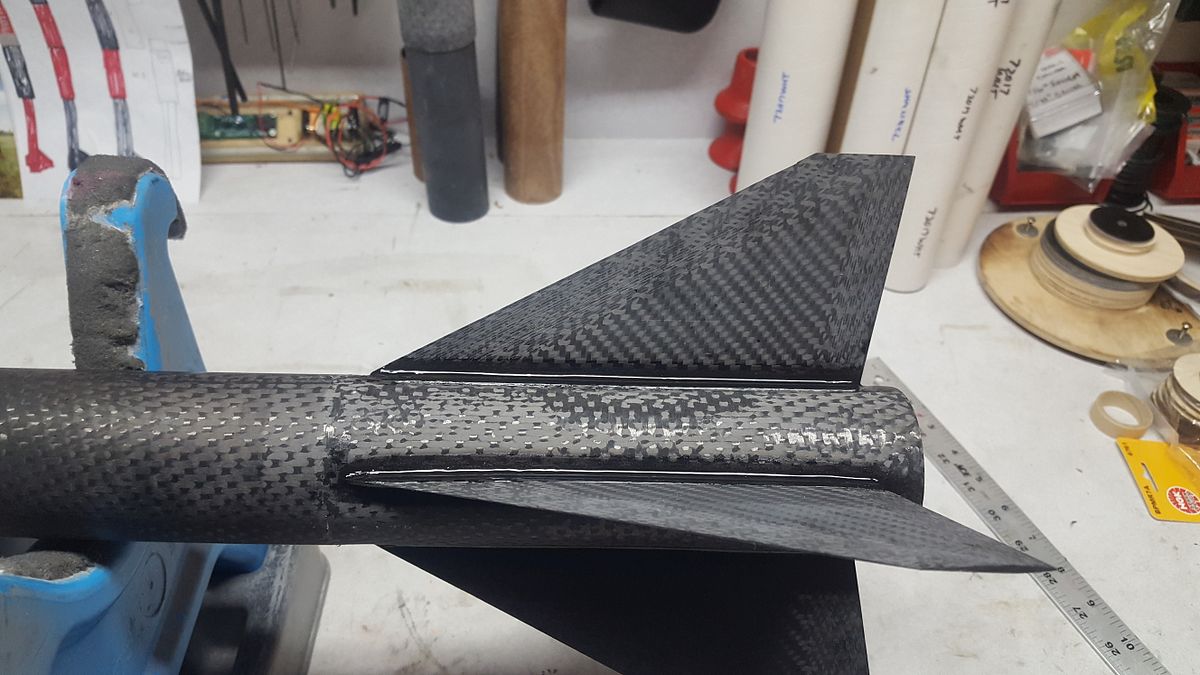

2. MAC Performance Rocketry. Holy cats, if you haven't picked up a kit from Mike, do it now! The fit and function, attention to detail, communication, and level of service is second-to-none! When I learned of a new product *cough* carbon fiber airframes *cough* I couldn't help but thing they'd compliment that Loki 54mm M1378 Red just fine! No better way to test out a new product than to punish it with the baddest 54mm motor to ever hit production! This shall be a test; of materials....and my building skills for sure!!!! Bonus, these tubes are sized exactly the same as Mike's canvas components, and therefore all 54mm components are interchangeable...cool!

3. Name & nomenclature: best I could come up with was Mac Pappy. Mac Daddy is too obvious, but Mac Pappy has the same kind of ring to it. One of my other passions is aircraft; particularly the classic war iron. One of the favorites is the Corsair; it's my Grandpa's favorite from his Navy days in WWII, I love the tales of the Corsairs flying over during his service. I've flown several r/c versions; it's certainly a favorite of mine as well. Greg Pappy Boyington was made famous in the TV series Baa Baa Black Sheep based on the Marine Corps' VMF-214 squadron of F4U Corsairs. Corsairs, nicknamed "Whistling Death" are often portrayed as darkly painted, mean, and known for causing all kinds of noise and mayhem; I liken this little rocket to the Corsair reputation!

One such Corsair with a number closely matching the OD of this screamer! (57mm roughly, but close enough!)

So what are we trying to accomplish here? Well, I want to fly the M1378 in a minimum sized airframe; testing out Mike Crupe's new carbon airframe, intending for a nominal (non-shredding) flight and successful recovery at Airfest this September. Will it be easy: no? This motor in a minimum diameter ship is a rocket killer. We'll see how we fare!

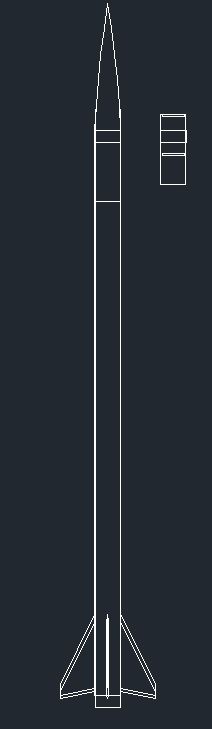

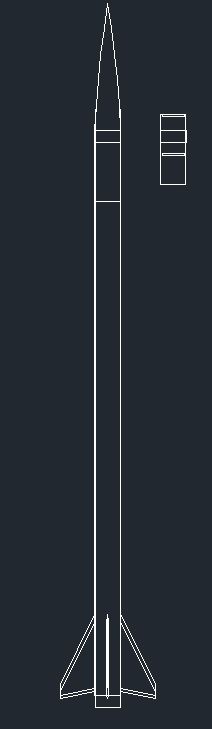

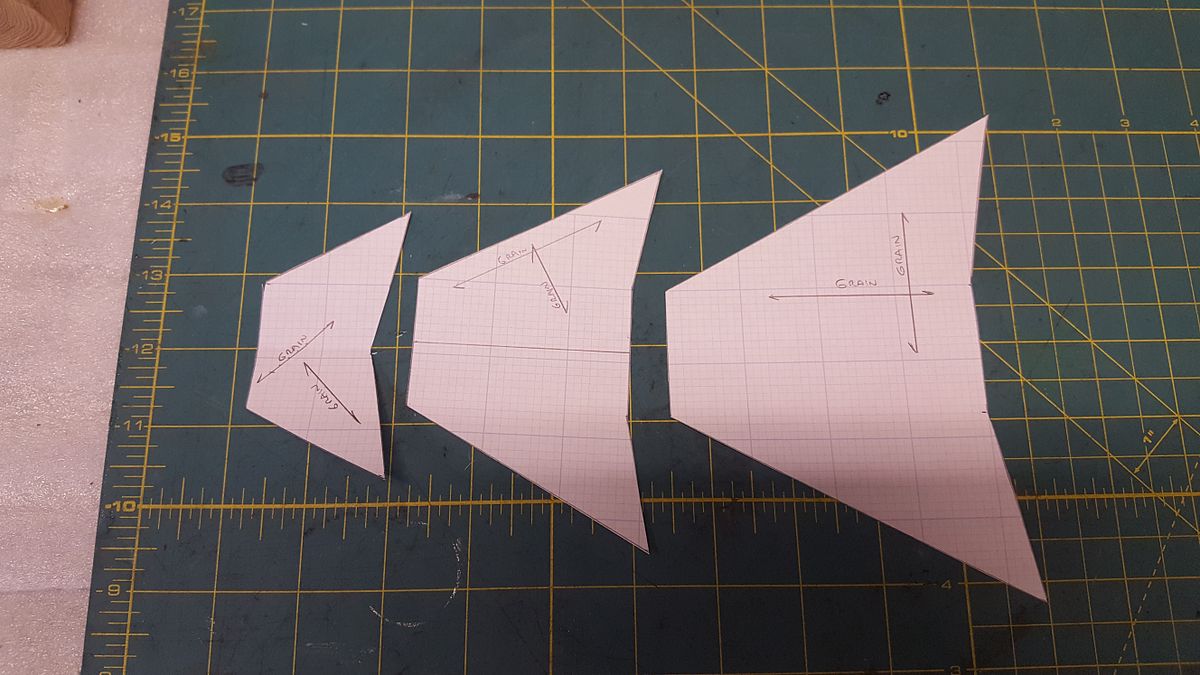

Photo of the simplistic design. Yes, there's more to it, but this silhouette give you an idea.

-Eric-

A few sources of inspiration.

1. Loki 54/4000 hardware. I've always liked the Kosdon, then AMW 54/2550 motors. I've always admired the Kosdon 2.1(54)-3300 hardware. When Loki turned the 54/4000 hardware loose, I jumped on the first run. When a 54mm M was certified, I had to have one. Now I gotta fly the darn thing!

2. MAC Performance Rocketry. Holy cats, if you haven't picked up a kit from Mike, do it now! The fit and function, attention to detail, communication, and level of service is second-to-none! When I learned of a new product *cough* carbon fiber airframes *cough* I couldn't help but thing they'd compliment that Loki 54mm M1378 Red just fine! No better way to test out a new product than to punish it with the baddest 54mm motor to ever hit production! This shall be a test; of materials....and my building skills for sure!!!! Bonus, these tubes are sized exactly the same as Mike's canvas components, and therefore all 54mm components are interchangeable...cool!

3. Name & nomenclature: best I could come up with was Mac Pappy. Mac Daddy is too obvious, but Mac Pappy has the same kind of ring to it. One of my other passions is aircraft; particularly the classic war iron. One of the favorites is the Corsair; it's my Grandpa's favorite from his Navy days in WWII, I love the tales of the Corsairs flying over during his service. I've flown several r/c versions; it's certainly a favorite of mine as well. Greg Pappy Boyington was made famous in the TV series Baa Baa Black Sheep based on the Marine Corps' VMF-214 squadron of F4U Corsairs. Corsairs, nicknamed "Whistling Death" are often portrayed as darkly painted, mean, and known for causing all kinds of noise and mayhem; I liken this little rocket to the Corsair reputation!

One such Corsair with a number closely matching the OD of this screamer! (57mm roughly, but close enough!)

So what are we trying to accomplish here? Well, I want to fly the M1378 in a minimum sized airframe; testing out Mike Crupe's new carbon airframe, intending for a nominal (non-shredding) flight and successful recovery at Airfest this September. Will it be easy: no? This motor in a minimum diameter ship is a rocket killer. We'll see how we fare!

Photo of the simplistic design. Yes, there's more to it, but this silhouette give you an idea.

-Eric-

But, it has flown in Kansas and Indiana in the past; it's a fast mover and I use it to test stuff out. Last time it was in Indiana, it hit Mach 2.7 and melted Proline 4100 lamination resin and a small layer of Cotronics on the leading edge. Manny captured the post flight furry critter photo.

But, it has flown in Kansas and Indiana in the past; it's a fast mover and I use it to test stuff out. Last time it was in Indiana, it hit Mach 2.7 and melted Proline 4100 lamination resin and a small layer of Cotronics on the leading edge. Manny captured the post flight furry critter photo.