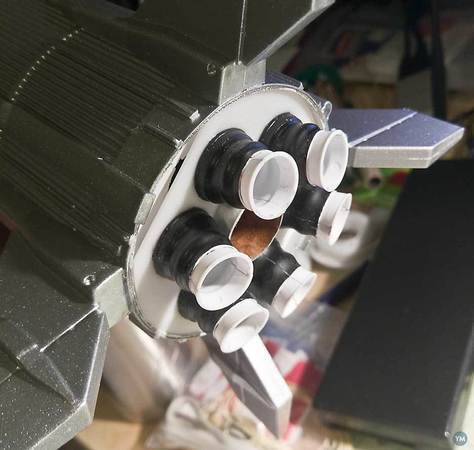

1. Thank you to all the people who have posted to this thread. I have read and re-read it so much that the print would be fading were I to have printed it; the build tips, lessons-learned, and insights have been invaluable. It has been a rather time and detail-intensive rocket, but I wanted to get it right. (No, the RCS nozzles haven't been glued on yet).

2. I initially thought this was a dumpy little rocket and didn't understand all the fuss over it. Now that I've learned its history, I see that it is a nifty Apollo test bed. I was given the kit last year and have been trying to get it (and my Saturn V) finished in time for commemorative launches this summer. Youtube video of the launch with the accidental live test was something to see, and I love that Estes includes the history lesson in the kit.

3. I did not use any regular plastic cement; I used either epoxy or CA.

4. I wound up using the Estes waterslide decals for the tower itself and the CM. I know that the American flags shouldn't be there, but I really like how they look, so I applied them. The only people who will know are those on this forum and a handful of other rocket geeks...

5. I printed out George's wrap for the SM. The print shop didn't have any glossy legal size, so I had them print it on legal paper, then copied it onto semi-glossy tabloid size and IMHO it came out quite well.

6. I kept getting some ripples using the double-sided tape, so I used the 3M 77 to apply the wrap. I did a test application on another cardboard tube and it laid down nicely. So naturally, when I did the real thing on the rocket, I wound up with a couple of small ripples/air bubbles. Like a Christmas tree, I'll keep that side toward the wall...

7. For the "United States" decal, I first soaked it in warm water per usual procedure, then put it in a 50/50 solution of water and white vinegar for about 30 seconds before applying. I cut the point off of a toothpick and used that as a stylus for making the decal set down in the grooves. That worked great for making the decal lie down in the corrugation.

8. I tried the gloss black under silver trick, fortunately on a test scrap of vacu-plastic. Even though both paints were the same Rust-Oleum brand, the silver wrinkled up horribly. So I went back to my usual process of cleaning the parts, wiping down with rubbing alcohol and painting.

9. I used the Titanium Silver Metallic Rust-Oleum Universal and painted it directly onto the rocket. The Universal comes in the cans with the funky shaped spray heads; it seems to be of better quality Rust-Oleum than the regular and I've had very good success with it, especially the metallics.

10. To apply the wrap, I masked off a 1/8" strip all the way around the edge, plus a 1/4" wide strip on the fuselage where the wrap ends come together. I used the 3M 77 on the wrap, then pulled off the tape while the adhesive was flashing. I applied the wrap to the rocket and then used a toothpick to put CA all around the masked off areas. I put a few rubber bands around everything and let it set up for an hour. That all went quite well, IMHO. I did cut a strip of thin posterboard to put around the forward circumference of the wrap.

Photos are attached. This'll probably be a one-and-done rocket where it'll get one launch and then be retired to the display shelf.

Again, thanks for all the info on how to build this properly.