. The other question I had was if I take one of those green scrub pads to the body it self before the gloss/polish, will it destroy the beauty of the material before the gloss? I want to give it a good scrub, to get any dirt or anything loose.

Waste of time. The green pads are about = 400 grit sandpaper & don't load up like s-paper does. The idea is too use them cause they contour to all the curves, nooks & crannies that paper won't. Build up 2-3 coats of clear, let dry overnight till hard, then use pad to buff down the finish, this will end up filling any imperfections with clear as you continue the process[several times] giving you a flat flawless glass smooth mirror gloss finish.

You can see what you are doing because after using the pad there will be dull areas and glossy spots. Those are the areas that need building up with clear the get the even coat. You know you are ready for final coats when you buff the finish and it's dull every where. The finish has been built up & buffed down enough that all imperfections are now filled and smooth.

Then ya hit it with the final coats after applying vinyl, if using any. Continue to coat, buff..... if ya want the vinyl to be deep in the finish for that pro-look.

In essence when finished you have applied around 10-12 coats, but have buffed off most, leaving you with a built up finish of 3-4 coats. This is how most show quality finishes are done.

Use something around 220 for the bare tube.[/QUOTE]

Thanks for the advice, today I acted upon your expertise and started the finishing step.

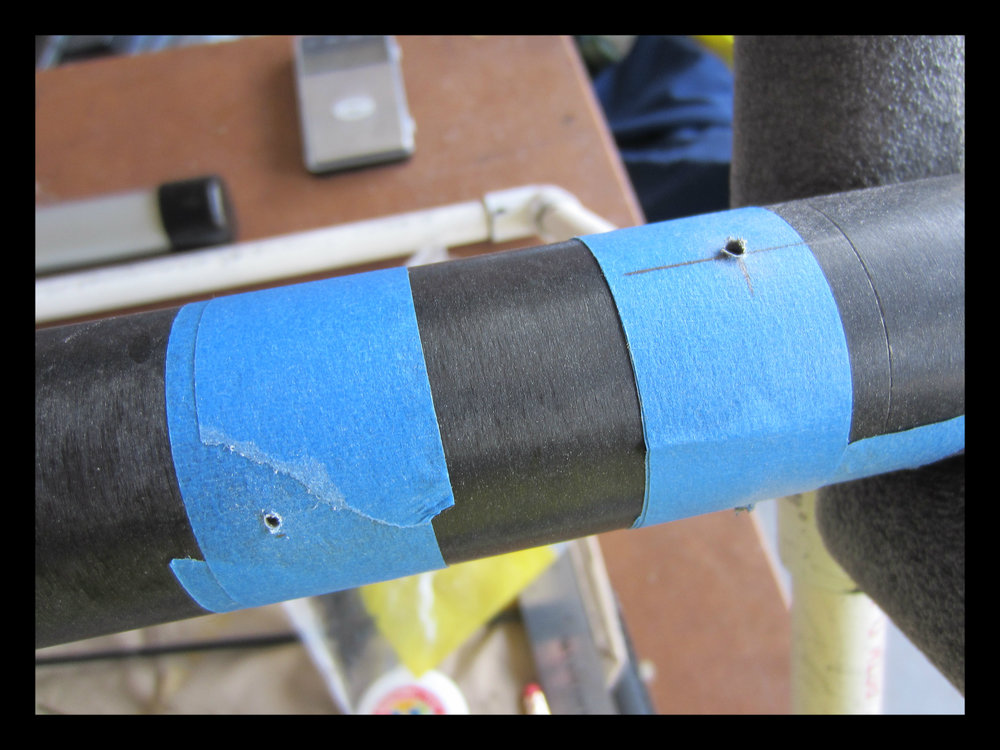

I went to home depot getting screws for my av bay and some other random things. I thought to myself, I better get some PVC to make a cool stand for holding the rocket while putting the clear coat on. Well my laziness got the best of me, and I said "I will figure something out at home". Lo and behold, the exquisite barstool.