You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Homemade Motor Retainers

- Thread starter qquake2k

- Start date

Help Support The Rocketry Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

MarkII

Well-Known Member

- Joined

- Jan 18, 2009

- Messages

- 8,250

- Reaction score

- 46

Although it is slightly more complicated to construct, it is far better from a safety standpoint to attach retainers with screws that thread into the rocket, rather that having them bolt onto a fixed metal stud that projects out of the rocket. Designing a hobby rocket with a spear-like metal projection, even if it is at the aft end, is not the safest of practices.

MK

MK

Ted Curtis

Well-Known Member

Old thread but, Quest 4runner has a four engine cluster held in by a washer, nut screwed into threaded rod tailing from aft. Always thought it was genius, never really pondered safety, doh!Although it is slightly more complicated to construct, it is far better from a safety standpoint to attach retainers with screws that thread into the rocket, rather that having them bolt onto a fixed metal stud that projects out of the rocket. Designing a hobby rocket with a spear-like metal projection, even if it is at the aft end, is not the safest of practices.

MK

The retainers that screw INTO threaded inserts still will have the screw project OUT the rear. I don't see it as a bigger issue than engine hooks that project out the end of the rocket. I'd be much more concerned about metal tipped nose cones at the FRONT of the rocket if it should come down ballistically.

Ted Curtis

Well-Known Member

Very astute observation!The retainers that screw INTO threaded inserts still will have the screw project OUT the rear. I don't see it as a bigger issue than engine hooks that project out the end of the rocket. I'd be much more concerned about metal tipped nose cones at the FRONT of the rocket if it should come down ballistically.

Andrew_ASC

UTC SEDS 2017 3rd/ SEDS 2018 1st

- Joined

- Sep 22, 2017

- Messages

- 3,883

- Reaction score

- 542

My favorite one was Nytrunner’s Big SAM using a hose clamp he found in a garage.

Can be as simple,complex,easy,cheap,heavy, light or expensive as you want it to be. Foil tape is about as cheap as it gets if you want reliability. Although foil tape itself is rather expensive. Think I paid $15 for my last roll?Can you guys show me pictures of your homemade motor retainers? I need ideas.

BTW here's a picture of my homemade engine retention system:

I hope you don't use masking tape on reloadable HPR motors . . .

why not? it's cheap and just as effective. Crazy Jim is probably one of the biggest proponents of friction fitting.I hope you don't use masking tape on reloadable HPR motors . . .

https://www.rocketryforum.com/threads/rookie-stupid-question.104748/#post-1191121

rharshberger

Well-Known Member

Yep! Masking tape for friction fit and aluminum HVAC foil tape for a secure wrap around motor tube and rear closure/thrust ring of motor.I hope you don't use masking tape on reloadable HPR motors . . .

why not? it's cheap and just as effective.

https://www.rocketryforum.com/threads/positive-motor-retention.94039/

Duster45

Well-Known Member

- Joined

- Jan 14, 2019

- Messages

- 138

- Reaction score

- 80

why not? it's cheap and just as effective. Crazy Jim is probably one of the biggest proponents of friction fitting.

https://www.rocketryforum.com/threads/rookie-stupid-question.104748/#post-1191121

Some years ago I lost a 38mm Dr. Rocket casing via friction fitting. Lucky that both the casing and the chute were ejected, so I didn't lose the rocket. I will always opt for positive retention except (maybe) when using 18mm BP motors.

Positive retention can cost less than a single roll of tape. It doesn't have to be elaborate; one tee-nut installed in the aft centering ring, one bolt to fit the nut, and a clip cut from a scrap of sheet metal, drilled and bent to a Z-shape. For redundancy, two teenuts, two bolts, two clips on opposite sides of the motor.

Best -- Terry

CoachSteve

Well-Known Member

Water bottle caps and threaded neck

- Joined

- Apr 13, 2013

- Messages

- 2,444

- Reaction score

- 1,363

If you're using electronics, you can also retain many reloads from the front-end using a threaded forward closure. I do this in preference to aft retention for larger motors, arranging it so that the bridle attaches to a threaded rod that goes into the forward closure.

beeblebrox

8 C6-0, 12 D11-9, 20 D20-0, 20 E5-0, 3 Cinerocs

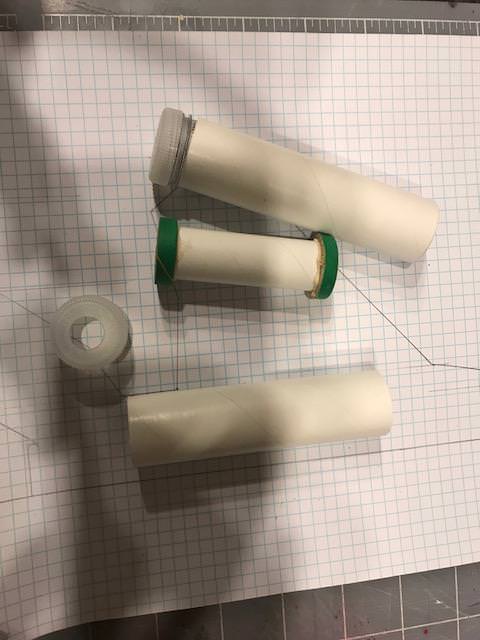

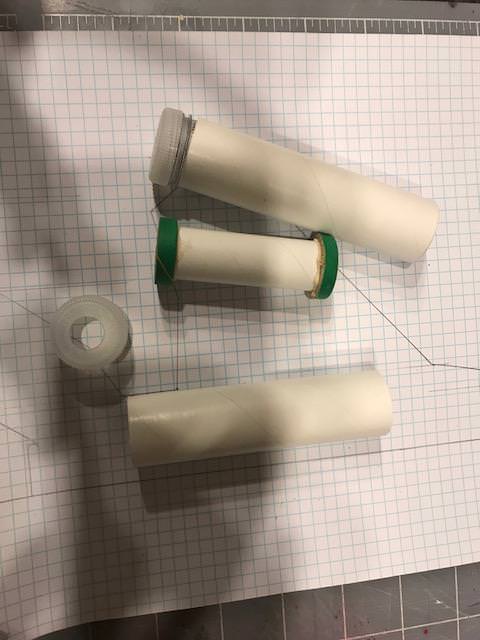

I've always used all thread bonded to the motor mount tube. One piece with 3 to 4 inchs of bonded area works on most applications. Sometimes a thin spacer is needed between threads and motor mount tube to allow for aft closure clearance.View attachment 385740 View attachment 385741

One of the best methods since the '70s!!! Lucerne Test Range Approved!

One of the best methods since the '70s!!! Lucerne Test Range Approved!

Don't MESS with "Old School" . . . !

I've used McMaster-Carr brass threaded inserts for Hardwood in 6-32 to screw into the rear centering ring. You can put those into any existing plywood CR.

Binder Design

Well-Known Member

- Joined

- Jan 17, 2009

- Messages

- 1,823

- Reaction score

- 266

Yep! Masking tape for friction fit and aluminum HVAC foil tape for a secure wrap around motor tube and rear closure/thrust ring of motor.

I pioneered that method for minimum diameter flights. Rock solid to mach 3+ in a rocket called Mr. Scary. 300g launch on a 38mm L motor.

Similar threads

- Replies

- 16

- Views

- 550

- Replies

- 8

- Views

- 391