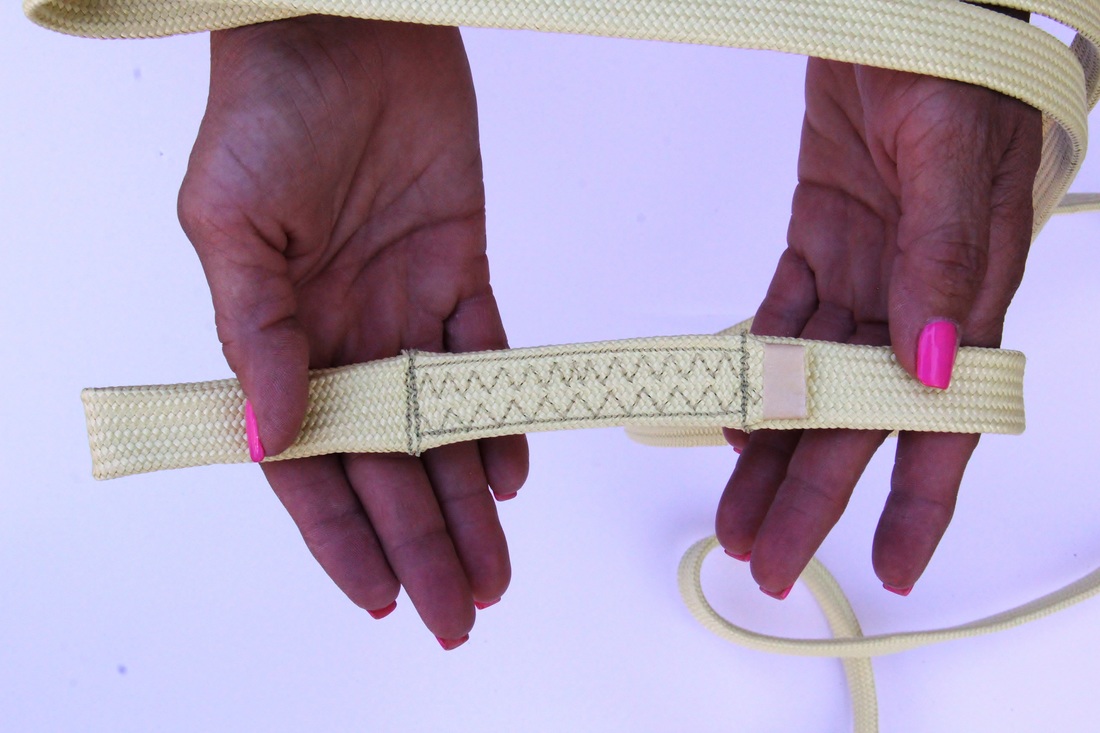

What I have done lacking that, is to use the loop to double over on itself and create a knot on the quick link of at least some expected properties.

Chuck,

I believe the knot Tony is referring to is called a "Lark's Head" .

ALL "knots" & "sharp bends" reduce strength . . . ( Including those "bends" your loops take around those quick links )

I did some research before making the above statement.

https://allaboutknots.blogspot.com/2010/11/knot-strength-structures-that-make.html

https://itrsonline.org/wordpress/wp...be.A-Review-of-Knot-Strength-Testing_2016.pdf

https://www.rescueresponse.com/much-strength-rope-loose-tie-knot

Please remember that my concerns are only the safety and success of your project, Chuck !

Dave F.

Last edited: