blackjack2564

Crazy Jim's Gone Banana's

Got my 5.5 Nike-Tomahawk from Madcow & began a build in 2 stage thread.

Cool setup.Welded up a launch pad for my nephew.

Launch my 3D printed scratch build named "Falcon" on an I180W.View attachment 367984View attachment 367985

Great picture Ben!

Double sided removable carpet tape works really well for shop jig hold downs (woodworking for the most part), I use it on my varous sanding jigs and "finger saver" extensions for small parts.

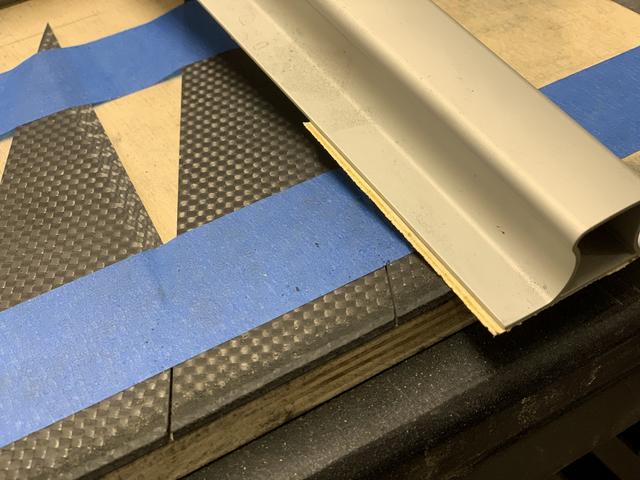

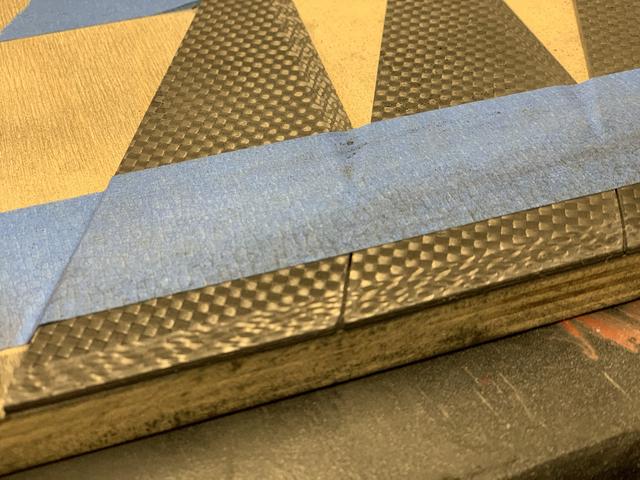

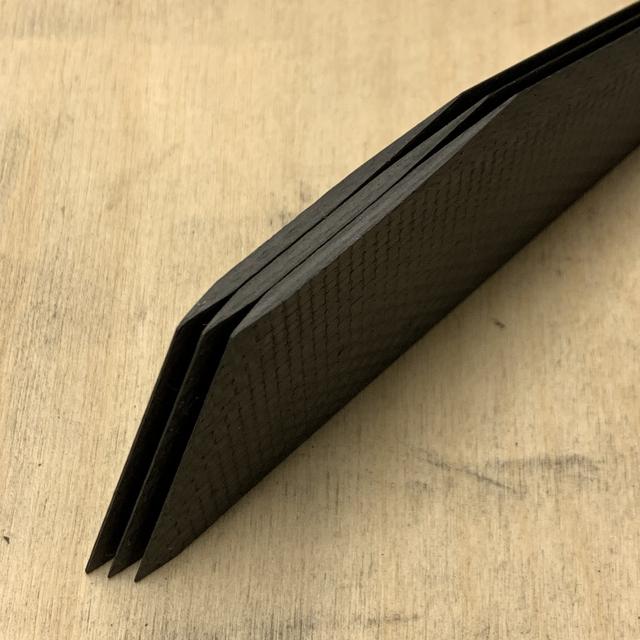

Ouch!Had to rip out faulty shock cord mounts from my minimum diameter rocket... *twice*...

Opened a package of Loki awesomeness courtesy of Chris' Rocket Supplies. Had it delivered at my work to preserve marital bliss....

Enter your email address to join: