jim fustini

Well-Known Member

- Joined

- May 24, 2009

- Messages

- 425

- Reaction score

- 5

Why did Estes stop production of core burner motors like the B-14?

Do you think they would ever make them again?

Do you think they would ever make them again?

Why did Estes stop production of core burner motors like the B-14?

Do you think they would ever make them again?

I knew about them, but I never got to see any back in the B14's heyday. (I couldn't afford them.) Was the ignition and motor burn visibly different from regular B motors? These "super motors" were still, after all, just B motors.I always thought of the B-14's as "Rocket Rippers". If you built it right, the rocket just ripped thru the air. IF you didn't, the fins ripped right off.

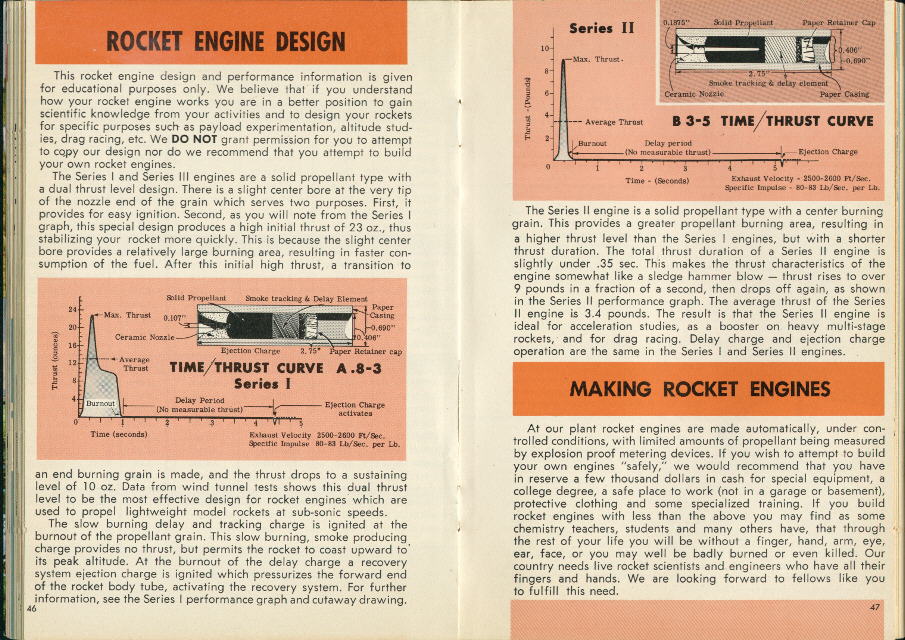

The B14 motors were discontinued in 1980 (79 is the last catalog they appear in. If you go back to the 1964 catalog, you'll find B3 motor listed that is what became the B14 (in '64, they were still labeling motors using the english system, so with the new labeling system, the B.8 became the B6 and the B3 became the B14). You can tell that the B3 was what became the B14 because it is noted as a Series II motor, whereas the B.8 was a Series I motor. Series I is the standard motors (A8, B4, B6, etc.) while Series II was the core burner (B14). For history's sake, there was a Series III motor, which were the same as series I but labeled S for short - for example, the A8-3S was the same as the A8-3 except that it was one inch shorter (1.75" instead of 2.75"). The Series III short motors were discontinued in 1973 when the mini motors (such as the A10-3T) came out.

Was there ever an A8-3S ??? The shorty motors used the original super thick casings and so a fully loaded motor was a B (B4). An A motor (A5) waws only half filled, and so to eliminate the dead weight of the super thick and empty casing, they cut off 1 inch.

When thinner and stronger casings came out, they were able to make the A8, the B6 and the C6 motor. They continued the A5 and B4 line even for a while after the new thin walled mini motors arrived, but eventually the A5 was dropped and the B4 was re-engineered for the new thin walled casing.

Cool story, bro!I know this guy who got some unmarked 18mm core burners from an estate of an old rocket dude......

I looked in and said ...

That part is the only honest and truthful part to this whole post.

CTI makes an F-240 V-max 24mm I have the hardware and reloads But I have yet to build a rocket to handle it . ( I will this winter) I seen one fly at my local club launch. It is one crazy little motor!:y:I'd love a full core burning C30(?)-0 :smile:

I flew 2 F240's in a Viper IV (airstarting 2 D12's). Lots of funCTI makes an F-240 V-max 24mm I have the hardware and reloads But I have yet to build a rocket to handle it . ( I will this winter) I seen one fly at my local club launch. It is one crazy little motor!:y:

There is such a thing as pressed "cored" motors, using a longer pintle tooling than that used to make the propellent grain end "dimple" found in Estes engines, but it's not particularly amenable to machine production methods used for mass produced motors... and the pressing is very hard on the tooling.

Why is it not amenable to mechanization, and how is it hard on the tooling?

I would ask the same. I could see the cost for mass production, and paying off the overhead to make a profit. But the ware on tooling?Why is it not amenable to mechanization, and how is it hard on the tooling?

[POW]Eagle159;250320 said:Heat?

I was asking about pressing the core into the grain, rather than drilling it out. Unless you're saying that pressing the core into the grain produces an exceptional amount of heat.

[POW]Eagle159;250329 said:But will pressing it into the core over and over very quickly keep a nice constant shape? I have no idea but just a thought...

Well, Estes is able to press dimples into BP grains at high speed, how would a core be different? I've looked at some other posts on this same subject, and it is apparently possible to press cores into BP grains using a hand press, Why shouldn't it be possible in an automated machine? My first guess would be space constraints in the Mabels...

[POW]Eagle159;250339 said:I think someone will have to help us on why it is soo unsafe to core BP...

While we're at it, does anyone know of any websites that describe the workings of the Mabels?

Enter your email address to join: