You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Upscale Space Shuttle full Stack ????

- Thread starter Hangar 11

- Start date

Help Support The Rocketry Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Hangar 11

Well-Known Member

- Joined

- Apr 24, 2009

- Messages

- 106

- Reaction score

- 0

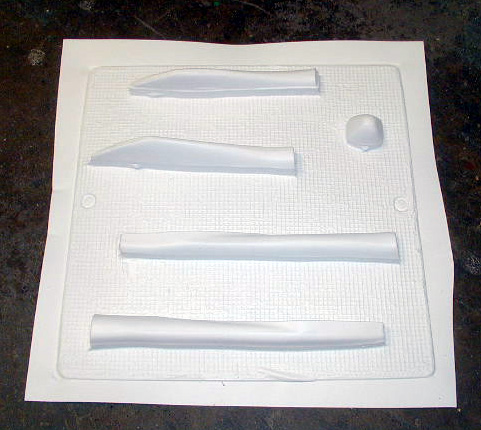

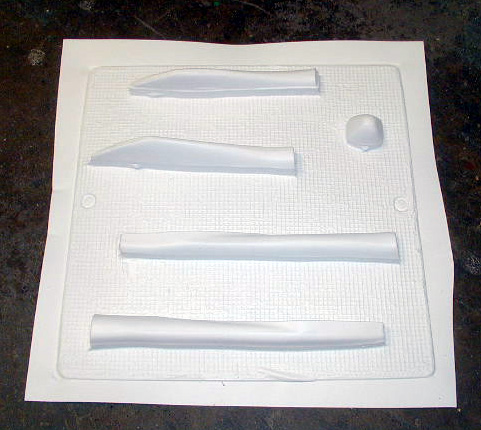

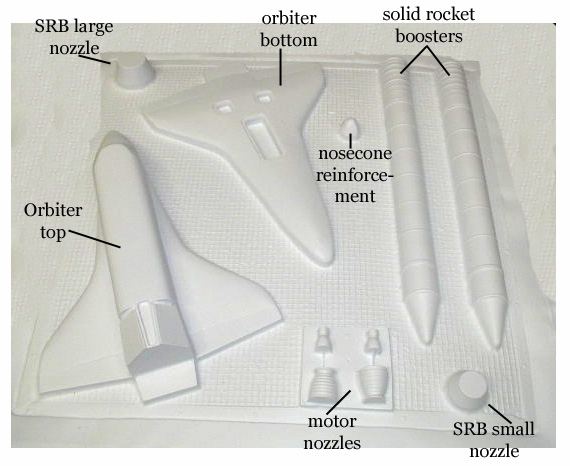

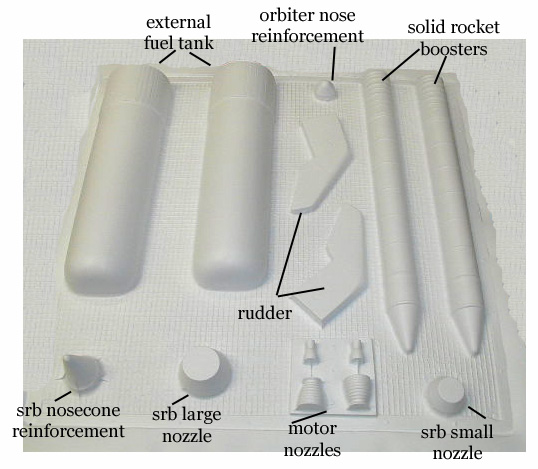

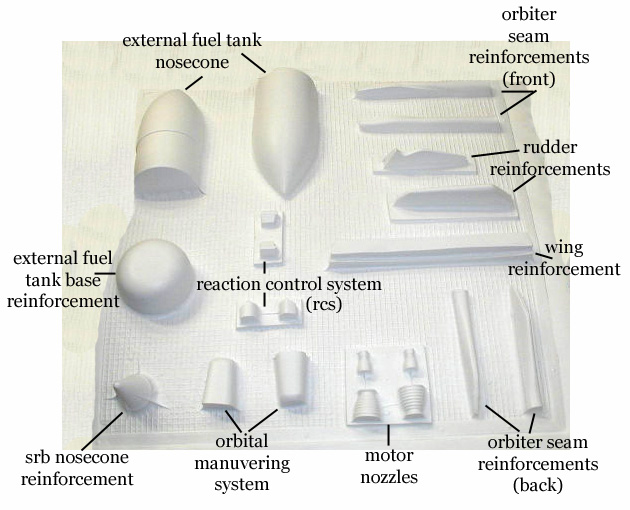

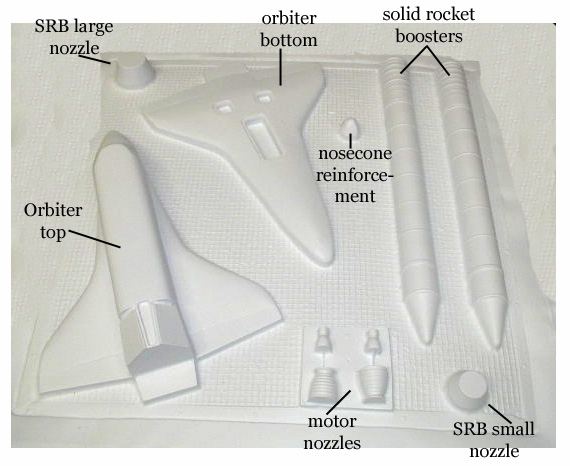

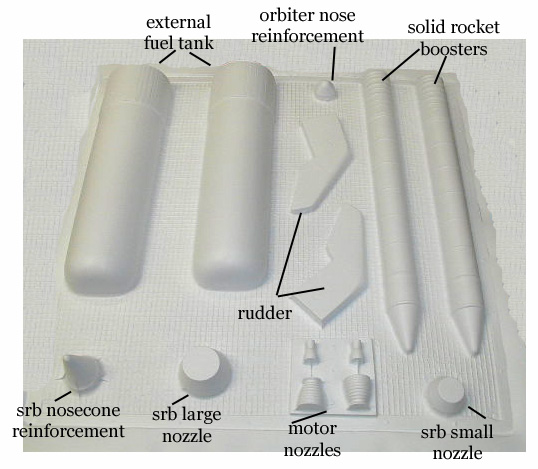

The first set of pulls from the molds were completed today... here are some pics of the parts we pulled.

The decal set is in the works......

substructure and servo mounts are on the board......

The plan is to boost the stack on 2 engines in the SRB's SRB's will have 54mm mmt.

The shuttle will separate and RC glide recover, the SRBs / main fuel tank will recover under chute.

I'm still undecided as to including a ducted fan, not for sustained flight but for increasing glide time and distance. Any reader thoughts on this option would be welcome.....

-----

-----

-----

-----

-----

The decal set is in the works......

substructure and servo mounts are on the board......

The plan is to boost the stack on 2 engines in the SRB's SRB's will have 54mm mmt.

The shuttle will separate and RC glide recover, the SRBs / main fuel tank will recover under chute.

I'm still undecided as to including a ducted fan, not for sustained flight but for increasing glide time and distance. Any reader thoughts on this option would be welcome.....

-----

-----

-----

-----

-----

Agent Titan

Well-Known Member

- Joined

- Jan 2, 2011

- Messages

- 549

- Reaction score

- 0

That looks amazing! If only I had the money available for it... Can't wait to see it done!

When will it be ready? What will it fly on? And the all important, how much is it going to cost us?

Wow.

Gary, I'm in!

If it comes out half as good as the X-15, this will be great.

BTW - I finally put together the glueless 4" rocket I purchased last year. Definitely worth the wait. You've opened me up to a whole new area within rocketry for me.

Gary, I'm in!

If it comes out half as good as the X-15, this will be great.

BTW - I finally put together the glueless 4" rocket I purchased last year. Definitely worth the wait. You've opened me up to a whole new area within rocketry for me.

MaxQ

Tripoli 2747

Looks pretty nice...only one question here...maybe two.

Has a prototype flown with engines in the SRB's?

Is this an "active guidance" kinda thing... to keep it flying stable and in the right direction?

Also, what scale is this?

Has a prototype flown with engines in the SRB's?

Is this an "active guidance" kinda thing... to keep it flying stable and in the right direction?

Also, what scale is this?

Last edited:

That was three questions Max, but who's counting?

The first set of pulls looks great, so I guess I need to improve my model building skills, learn to fly a R/C shuttle and get my L1 certification.... :y: Not to mention the cost of a kit like this....

Might be doable by the time it becomes available.

The first set of pulls looks great, so I guess I need to improve my model building skills, learn to fly a R/C shuttle and get my L1 certification.... :y: Not to mention the cost of a kit like this....

Might be doable by the time it becomes available.

ben_ullman

Well-Known Member

- Joined

- Jan 17, 2009

- Messages

- 1,523

- Reaction score

- 2

Looks pretty nice...only one question here...maybe two.

Has a prototype flown with engines in the SRB's?

Is this an "active guidance" kinda thing... to keep it flying stable and in the right direction?

Also, what scale is this?

im thinking somewhere around 1/54th with 6" dia ET.

Ben

kjohnson

mox nix

- Joined

- Jan 19, 2009

- Messages

- 1,368

- Reaction score

- 69

Looks really good. For my personal tastes and situation, it's too large for me to be interested. Now at half this size.. then I'd have to seriously think about it.

The EDF idea is interesting, maybe offer it as an add on option if it's not too much work to have to build the structure differently. I probabaly wouldn't spring for it.

For controls of the glider, are you thinking elevator and rudder or elevons?

kj

The EDF idea is interesting, maybe offer it as an add on option if it's not too much work to have to build the structure differently. I probabaly wouldn't spring for it.

For controls of the glider, are you thinking elevator and rudder or elevons?

kj

- Joined

- Jan 20, 2009

- Messages

- 297

- Reaction score

- 3

Nice, I would be interested!

-Rich

-Rich

- Joined

- Jan 17, 2009

- Messages

- 5,204

- Reaction score

- 1,547

Great project.

I have given advice on Space Shuttles before. The best thread is this one:

https://www.rocketryforum.com/showthread.php?t=7318

I said a lot, gave a lot of examples, drawings, make it light, thrust vectors, make it light, and a bunch of other things (and make it light).

There really is nothing new on this project that I didn't discuss in that thread.

BTW - the best video of one of my test flights (1/72 stack, RC) is here:

https://www.youtube.com/watch?v=OQbt2VoIuZo

On the final (5th) Page of the thread, I announced a shuttle kit I was going to produce, at 1/110 scale. But, I do not know if I ever will do that. At best, it is on the back burner, way in the back.

On my home page, more shuttle stuff, as included in the thread link above.

https://homepage.mac.com/georgegassaway/GRP/Scale/SHUTTLE.htm

- George Gassaway

I have given advice on Space Shuttles before. The best thread is this one:

https://www.rocketryforum.com/showthread.php?t=7318

I said a lot, gave a lot of examples, drawings, make it light, thrust vectors, make it light, and a bunch of other things (and make it light).

There really is nothing new on this project that I didn't discuss in that thread.

BTW - the best video of one of my test flights (1/72 stack, RC) is here:

https://www.youtube.com/watch?v=OQbt2VoIuZo

On the final (5th) Page of the thread, I announced a shuttle kit I was going to produce, at 1/110 scale. But, I do not know if I ever will do that. At best, it is on the back burner, way in the back.

On my home page, more shuttle stuff, as included in the thread link above.

https://homepage.mac.com/georgegassaway/GRP/Scale/SHUTTLE.htm

- George Gassaway

Last edited:

- Joined

- Jan 17, 2009

- Messages

- 5,204

- Reaction score

- 1,547

I'm curious.

What are the weights for the empty shells?

The Orbiter alone, ET alone, and each SRB?

Since they are white, are those vac-formed? Or fiberglass?

- George Gassaway

What are the weights for the empty shells?

The Orbiter alone, ET alone, and each SRB?

Since they are white, are those vac-formed? Or fiberglass?

- George Gassaway

Hangar 11

Well-Known Member

- Joined

- Apr 24, 2009

- Messages

- 106

- Reaction score

- 0

WOW... see what happens when I get busy in the store... I miss all the fun stuff here..... Apologies on the delayed reply.....

The shells are vac formed, VERY VERY light. current design looks like we will be using a light foam liner with a minimal frame.

Weights of trimmed vac forms Shuttle top & bottom 16 oz. SRB 4 OZ each main tank 20 OZ

Approx Lengths shuttle 30" tip to tail , Span 21" , SRB 36" length , main tank 40 " Length x 7.5" Dia

The SRBs use PML 3.0 phenolic tubes inside with std CR etc.

I'm thinking about releasing the SRB's as a stand alone kit any interest on flying an SRB ?????

George G I'm looking for a helper / builder on this project....

looks like you might have the credentials [ GRIN ]

As for When , We have 2 prototypes in process.... more specifically one is being built and mine is looking for a builder.... running my store keeps me too busy to build. I'll stick to the designing...... for now......

A third mock up is being built for decal and markings.... pics as soon as I get the model back..... Same decal person who does my X-15's and Deep space Explorer [ AKA upscale rubicon 6" dia 54mm mmt ]

Also pulled some "Darth Shuttles" in Black..........Way cool.......

How Much..... TBD.... trying to keep the cost down..We are looking

many vac formed parts. body tubes, decals set, CR,

I'm considering offering it as a short kit. vac forms only

No we have not flown any yet..... design is for boosting on 2 engines in the SRB's 29 ,38 or 54. shuttle recovers as an RC glider [ might have a boost or DF option ] SRB's and main tank recover under chute deployed from the main tank.

Please keep the comments coming .... better yet drop by the store and check out the parts.....

The shells are vac formed, VERY VERY light. current design looks like we will be using a light foam liner with a minimal frame.

Weights of trimmed vac forms Shuttle top & bottom 16 oz. SRB 4 OZ each main tank 20 OZ

Approx Lengths shuttle 30" tip to tail , Span 21" , SRB 36" length , main tank 40 " Length x 7.5" Dia

The SRBs use PML 3.0 phenolic tubes inside with std CR etc.

I'm thinking about releasing the SRB's as a stand alone kit any interest on flying an SRB ?????

George G I'm looking for a helper / builder on this project....

looks like you might have the credentials [ GRIN ]

As for When , We have 2 prototypes in process.... more specifically one is being built and mine is looking for a builder.... running my store keeps me too busy to build. I'll stick to the designing...... for now......

A third mock up is being built for decal and markings.... pics as soon as I get the model back..... Same decal person who does my X-15's and Deep space Explorer [ AKA upscale rubicon 6" dia 54mm mmt ]

Also pulled some "Darth Shuttles" in Black..........Way cool.......

How Much..... TBD.... trying to keep the cost down..We are looking

many vac formed parts. body tubes, decals set, CR,

I'm considering offering it as a short kit. vac forms only

No we have not flown any yet..... design is for boosting on 2 engines in the SRB's 29 ,38 or 54. shuttle recovers as an RC glider [ might have a boost or DF option ] SRB's and main tank recover under chute deployed from the main tank.

Please keep the comments coming .... better yet drop by the store and check out the parts.....

Last edited:

BrianWolfe

Member

- Joined

- Apr 29, 2011

- Messages

- 20

- Reaction score

- 0

I'm curious.

What are the weights for the empty shells?

The Orbiter alone, ET alone, and each SRB?

Since they are white, are those vac-formed? Or fiberglass?

- George Gassaway

George here are the weights for the plastic skins only:

Orbiter body top and bottom 15.1 oz.

SRBs 6.9 oz each

ET w/o nosecone 13.4 oz.

ET nosecone 6.4 oz.

OMS .7 oz.

Orbiter tail fin 2.8 oz.

George do you have RockSim data in any scale that I could adjust to size for this approximately 1/48 scale model.

thanks,

Brian

- Joined

- Jan 17, 2009

- Messages

- 5,204

- Reaction score

- 1,547

George do you have RockSim data in any scale that I could adjust to size for this approximately 1/48 scale model.

No Rocksim file.

I did it with, as Spock (and Peter Alway) might say, Stone knives and bear skins.

Well, cardboard cut-out anyway, for the stability aspect.

And in later years when crude computer flight sims were available (and I had a computer), I simply worked out by hand what the approximate frontal area was for the whole stack, and plugged that in place of a tube diameter. Plus the expected weights (best case and worst-case). That helped to see what certain type engine types would produce for crude ballpark altitudes.

I would not trust any flight sim, even Rocksim, to calculate the stability of a shuttle. At least not rocket hobbyist type flight sims.

The only practical way I trust for something that complex is "TestFlightSim", using "SmallStabilityPrototypeSim", which gives a definitive Yes/No answer that can be trusted for the real model way more than anything else.

In other words, a small shuttle stack model, test flown in the real world.

- George Gassaway

Last edited:

- Joined

- Jan 18, 2009

- Messages

- 1,758

- Reaction score

- 1,434

Looking for an update on the Shuttle. Hows it coming?????

BrianWolfe

Member

- Joined

- Apr 29, 2011

- Messages

- 20

- Reaction score

- 0

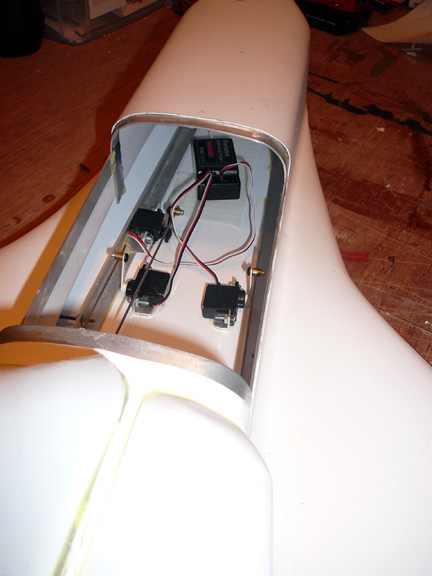

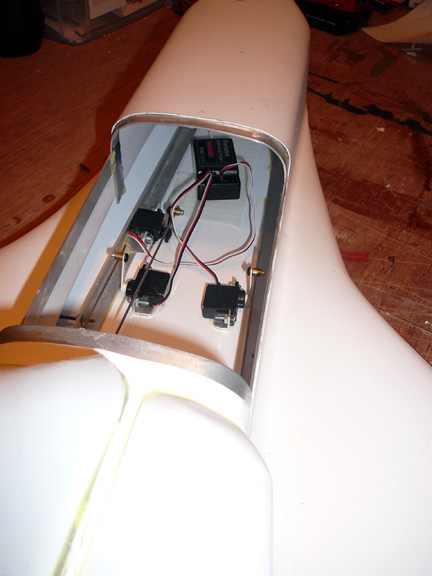

I have all the parts. Reinforced the glider with .060 x 1/2" x 1/2" aluminum angle. Installed three micro servers which now move the elevons and rudder. Making more molds for reinforcement strips to strengthen the horizontal seam. Hoping to fly at NERRF.

BrianWolfe

Member

- Joined

- Apr 29, 2011

- Messages

- 20

- Reaction score

- 0

Orbiter is coming along well. Weighs in at 2 lbs. 7 oz. All assembled servos in place, elevons and rudder working.

Aluminum stiffeners:

vinyl reimforcements for horizontal seam:

reinforcements in place:

clamped:

Threaded rod stiffeners:

servo compartment:

Assembled orbiter:

Aluminum stiffeners:

vinyl reimforcements for horizontal seam:

reinforcements in place:

clamped:

Threaded rod stiffeners:

servo compartment:

Assembled orbiter:

Last edited:

MaxQ

Tripoli 2747

Grooovy.

Elevon mixing....ala delta config. with computer radio?

I see two servos w/o no mechanical mixing....linked to elevons.

Full length rudder used - for yaw/steering? Coordinated with elevon?

I see a third servo ....maybe that's for orbiter release. Maybe not.

BTW: what scale are we doing here?

Elevon mixing....ala delta config. with computer radio?

I see two servos w/o no mechanical mixing....linked to elevons.

Full length rudder used - for yaw/steering? Coordinated with elevon?

I see a third servo ....maybe that's for orbiter release. Maybe not.

BTW: what scale are we doing here?

Last edited:

Hangar 11

Well-Known Member

- Joined

- Apr 24, 2009

- Messages

- 106

- Reaction score

- 0

Elevon mixing YES..... computer radio... yes.. .... not required but once you fly a computer radio... everything else is rubbin 2 sticks together in the rain....

Rudder coordination if your radio supports it.. [ our does ]

I'm thinking ~1/48th scale.... actual measurments are posted earlier in this thread... somebody with a slide rule please verify the calculations... I don't trust these damn calculators......

More progress today.... perimeter supports tested.... made 3 more molds for the vertical stab assembly.

Worked on alternatives to the foam filling.... $$$$ and time consuming... came up with stiffners which reduced weigh and cost....

buttoned up alot of ends today.... more pics will be posted on Sunday....

on Sunday...

COMPLETE Vacform sets are on sale now.... ADVANCED modelers ONLY please... With the stiffners there are ~30 vacformed parts.

I consider these "short kits" Vacformed parts ONLY.. builder adds EVERYTHING ELSE...... to complete the model.

Contact me at 845-926-1959 or [email protected] if your ready......

WARNING... In case it is NOT clear.. these are VACUUM formed parts made from a vinyl material. Advanced assembly techniques are required.

If your "fillet challenged" on your 3 fins and a nose cone kits this project is probably not for you at this time......

Rudder coordination if your radio supports it.. [ our does ]

I'm thinking ~1/48th scale.... actual measurments are posted earlier in this thread... somebody with a slide rule please verify the calculations... I don't trust these damn calculators......

More progress today.... perimeter supports tested.... made 3 more molds for the vertical stab assembly.

Worked on alternatives to the foam filling.... $$$$ and time consuming... came up with stiffners which reduced weigh and cost....

buttoned up alot of ends today.... more pics will be posted on Sunday....

on Sunday...

COMPLETE Vacform sets are on sale now.... ADVANCED modelers ONLY please... With the stiffners there are ~30 vacformed parts.

I consider these "short kits" Vacformed parts ONLY.. builder adds EVERYTHING ELSE...... to complete the model.

Contact me at 845-926-1959 or [email protected] if your ready......

WARNING... In case it is NOT clear.. these are VACUUM formed parts made from a vinyl material. Advanced assembly techniques are required.

If your "fillet challenged" on your 3 fins and a nose cone kits this project is probably not for you at this time......

Grooovy.

Elevon mixing....ala delta config. with computer radio?

I see two servos w/o no mechanical mixing....linked to elevons.

Full length rudder used - for yaw/steering? Coordinated with elevon?

I see a third servo ....maybe that's for orbiter release. Maybe not.

BTW: what scale are doing here?

sodmeister

Well-Known Member

- Joined

- Aug 1, 2009

- Messages

- 6,963

- Reaction score

- 36

Bobby, just to clarify.You say the parts are "vinyl" or do you mean "styrene" ? If the parts are vacform vinyl ,what type of adhesive is being used ?

Looks great BTW ,and will keep this kit in mind

Paul T

Looks great BTW ,and will keep this kit in mind

Paul T

Hangar 11

Well-Known Member

- Joined

- Apr 24, 2009

- Messages

- 106

- Reaction score

- 0

No not PS or polystyrene.. the plastic is in the vinyl family and very "tough" , durable, and appropriate for the application. There are many adhesives that can be used from low cost liquids to high end 2 part gap filling compounds.

Thank you for your interest and comment.

Bobby B

Thank you for your interest and comment.

Bobby B

Bobby, just to clarify.You say the parts are "vinyl" or do you mean "styrene" ? If the parts are vacform vinyl ,what type of adhesive is being used ?

Looks great BTW ,and will keep this kit in mind

Paul T

sodmeister

Well-Known Member

- Joined

- Aug 1, 2009

- Messages

- 6,963

- Reaction score

- 36

I see Bobby,thanks for the clarification.I would suspect that polystyrene would have been too brittle for such an application and for the size ,as thicker styrene would be very hard to vacform ,if not impossible.

Paul T

Paul T

BrianWolfe

Member

- Joined

- Apr 29, 2011

- Messages

- 20

- Reaction score

- 0

Very thick styrene would not be a problem to vac-form, it would be a weight problem for use as a glider.

The plastic is Boltaron. .030 thickness. Comparatively very strong and flexible compared to styrenes.

The plastic is Boltaron. .030 thickness. Comparatively very strong and flexible compared to styrenes.

sodmeister

Well-Known Member

- Joined

- Aug 1, 2009

- Messages

- 6,963

- Reaction score

- 36

Very thick styrene would not be a problem to vac-form, it would be a weight problem for use as a glider.

The plastic is Boltaron. .030 thickness. Comparatively very strong and flexible compared to styrenes.

Interesting, good to know !

I googled boltaron ,seems the perfect choice for this application.

Cheers

Paul T

Last edited:

BrianWolfe

Member

- Joined

- Apr 29, 2011

- Messages

- 20

- Reaction score

- 0

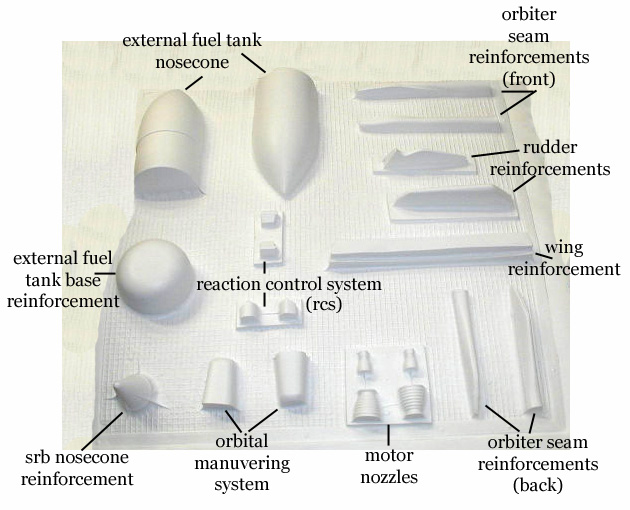

The vac-form shuttle is ready. It required 32 molds and 46 plastic parts:

Orbiter:

Body top

Body bottom

Rudder left

Rudder right

Main OMS left

Main OMS right

4 pieces OMS back add ons

6 Main nozzle halves

4 OMS nozzle halves

Nosecone exterior

Nosecone interior

4 edge reinforcements

Interior wing tip to wing tip reinforcement

2 rudder reinforcements

SRBs (For total of two)

4 main body halves with nosecone

2 large nozzle

2 small nozzle

2 nozzle nosecone reinforcements

External fuel tank

2 main body tube

2 nosecone halves

2 nosecone reinforcements

Fuel tank bottom reinforcement

The four vac-form sheets look like this:

Talk to Bobby about purchasing.

Orbiter:

Body top

Body bottom

Rudder left

Rudder right

Main OMS left

Main OMS right

4 pieces OMS back add ons

6 Main nozzle halves

4 OMS nozzle halves

Nosecone exterior

Nosecone interior

4 edge reinforcements

Interior wing tip to wing tip reinforcement

2 rudder reinforcements

SRBs (For total of two)

4 main body halves with nosecone

2 large nozzle

2 small nozzle

2 nozzle nosecone reinforcements

External fuel tank

2 main body tube

2 nosecone halves

2 nosecone reinforcements

Fuel tank bottom reinforcement

The four vac-form sheets look like this:

Talk to Bobby about purchasing.

- Joined

- Jan 18, 2009

- Messages

- 1,758

- Reaction score

- 1,434

Those pulls look awesome. Very little webbing. Two questions; first, will Tenax 7R work on this material and second, what is the cost?

Similar threads

- Replies

- 44

- Views

- 2K