I'm not sure it's really relevant, or anyone cares, But I finally flew the MAX on the line yesterday.

A Seattle San Fran turn. About 5 hours of flying for 2 legs.

1st impressions are all very positive. It flew very nice and the flight controls are very balanced. As a longtime

737 driver I was comfortable in the cockpit, a few secondary controls/switches have been moved but everything is logical. The biggest gripe is they moved the rudder trim knob about 1/2 an inch forward on the center panel. I never look for it, i just reach back for it and because of muscle memory I kept just missing it.

No big deal, just a minor "Doh".

The displays are beautiful, and the information is very well presented.

I don't normally do the walk around, but I did to get a handle on the outside changes. It's one thing to see photo's or look at it from a distance....Oh, who am I kidding I just wanted to check it out!

It has.... huge tracts of open land! Check out the Leap! Massive for a single aisle aircraft.

And the blades are a work of art.

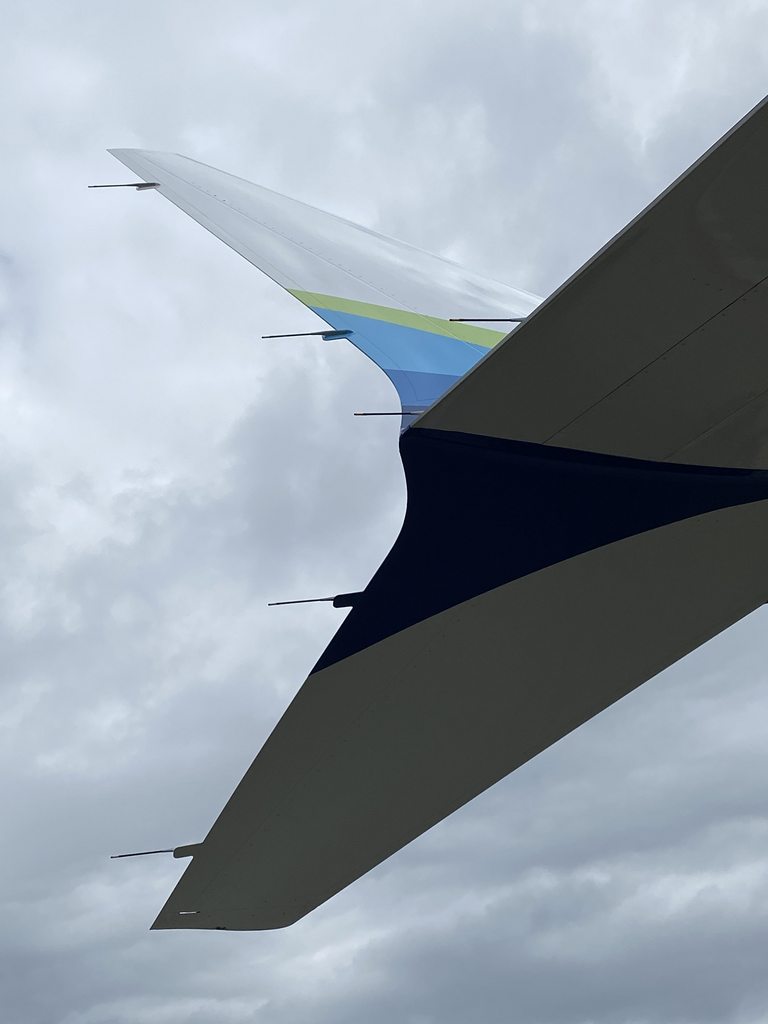

The new winglets sick out farther than on the NG, I'll have to be carful on the ground.

Taxiing is interesting, the Leap's have so much idle thrust it scoots along, and the carbon brakes really

work good! That takes some getting used to.

The sound the engines make on take off is just cool! The kind of growl rather than buzz.

But the cruise fuel burn was incredible! At Mach .78 and 37,000ft, with a full (170 passengers) aircraft our fuel burn was 2320 pounds of fuel per hour for each engine!

To give a comparison, the 737-900NG would be burning about 3100# per side.

We have A-321NEO's also, they are incredible also on the fuel burn but still higher than the MAX. I'll have to ask around, but I think the Airbus runs around 2500 Pounds per hour per side.

Airliners are revenue generation machines, as such the MAX is very, very good. As a pilot it was very pleasant fly, and our passengers seem to like riding in it.