So...

With the motivation of Prophecy, I decided to build a "NEW," rocket in ~2 days time and then hit the road for BALLS. This may sound familiar to some. Prophecy really deserves a lot of credit here, without him I would of never proceeded. I would have just scratched the build and started over from scratch… thats my nature. That is something very easy to do especially when you have just done a very similar project and are helping on a scaled up one.

So my new plan of attack was to go with what I knew best, big fillets with tip-to-tip over them. Funny how things got back to me… anyways this strangely put me back into my comfort zone and would make this more of a true

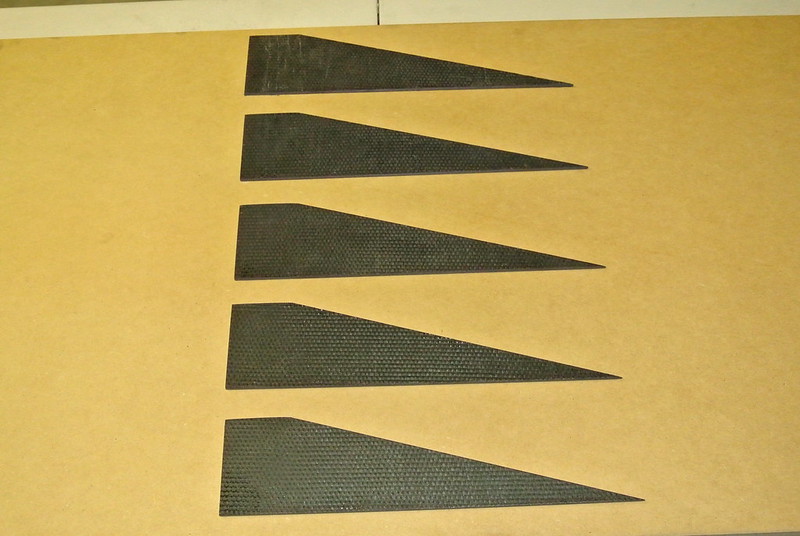

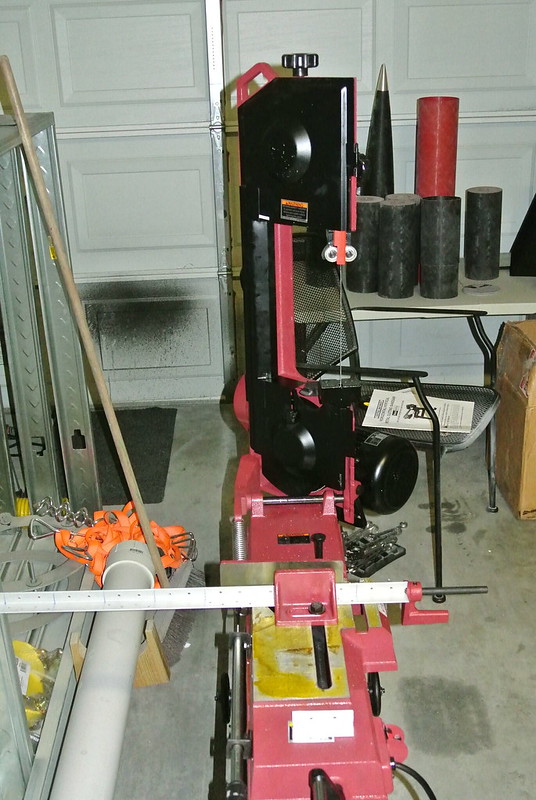

all composite vehicle. In order to get the fins/airframe ready for fin tack on, required some HEAVY removal of Cotronics 4525 epoxy. After about 2 hours of electric sanding with a random orbital sander and about twenty five 60 grit discs later, I was back at square one. I tacked the fins on with the exact same method as used before right after removing the excess epoxy and cleaning them up.

The airframe after taking down all the built up 4525… not an easy thing to do.

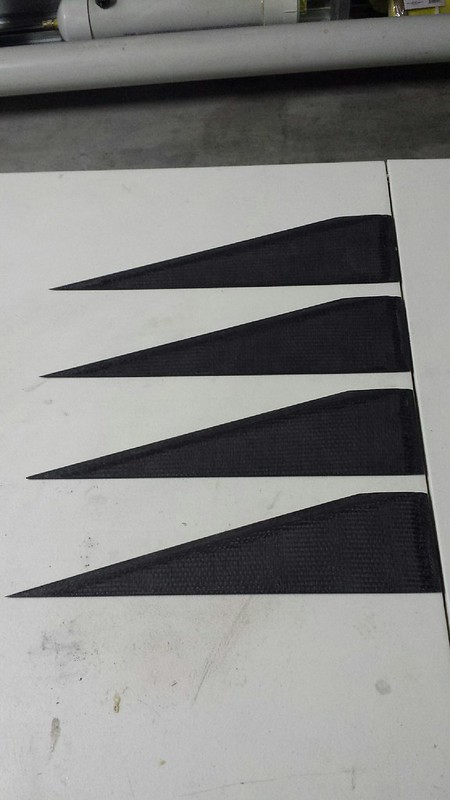

The fins after "cleaning up," the 4525.

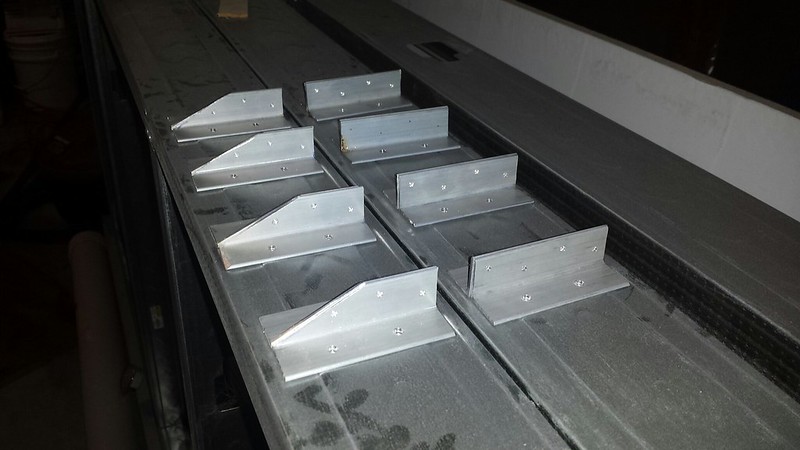

So the next step was to measure, mark, and tape off where the fins were planned to be tacked on. So here again is where I shoot myself in the foot. Instead of mixing epoxy and going with my regular method of filleting, I thought it would be a great idea to push carbon fiber strands into the fillet instead of having random oriented fibers. So the plan was to put down 3/4 of the fillet, push CF into the fillets and then lay the remain 1/4 of epoxy over it to aide in smoothing them out. Sounded good except I didn't have enough epoxy, it was harder than I thought (and messier than I thought), and I didn't check the length of my fibers that my girl had cut or me. All my fault for trying to do this in a rush… I know. After the first 2 fillets I decided it would be easier to get them as close as possible and then sand the excess fibers off and smooth the fillets. Wrong! It helped a bit but was no easy task. The fillets came out big and ugly and it was a good learning process. I had told myself before I would not launch this way again… but I did. I mean it this time… if a project is not done the trip is canceled. Enough ranting. So the fillets had areas that needed to be filled (to challenging to take it all down). It took about 2 hours to do all the fillets for the rocket. That includes the 5 min at 250F cure but does not include the partially failed attempt at sanding them down.

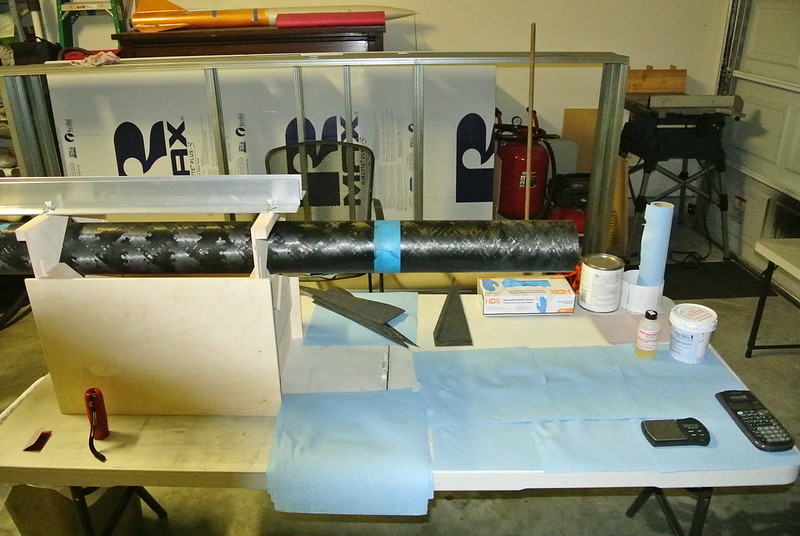

All the fins tacked back on. Area is measured, marked, and taped at 0.75" for the soon to be fillets.

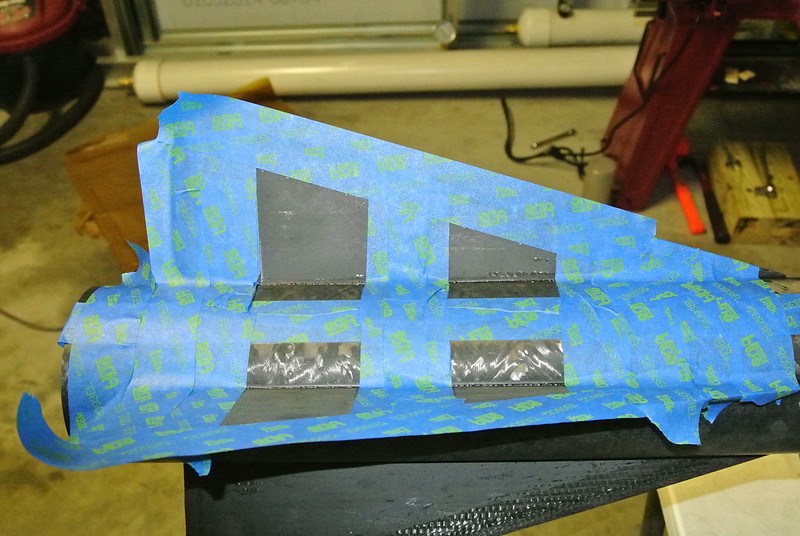

Fillet partially laid and carbon fiber strands laid on top to be pressed into place. I ended up pulling out about half of the fiber that you see there. Started out laying them nice then it got messy and hard to a just let them fall as they would. Defeated the whole purpose of this, I know.

Pressed down and what little epoxy that I had was laid on top.

Sanded and you can see the little gaps that I was talking about. Ended up filling them with more epoxy.

Another shot. The carbon fibers really made a mess… good lesson though.

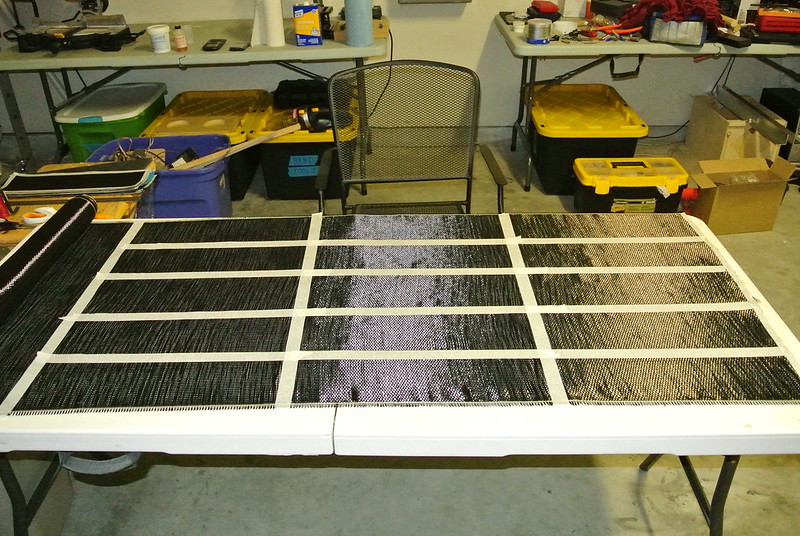

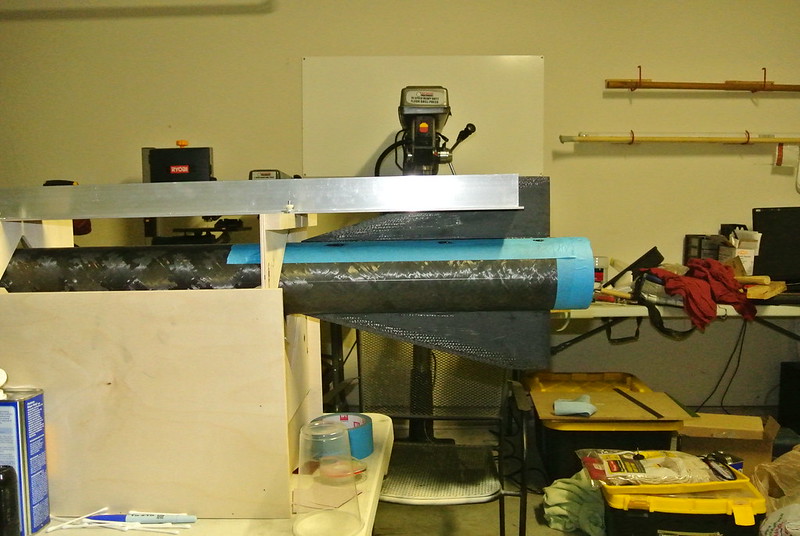

4 layers of tip-to-tip were applied with slightly standard 3k fabric. At this point all I had available was Aeropoxy so it is what I used. Not my favorite but if done in a decent manner could work.

Another shot of the tip-to-tip.

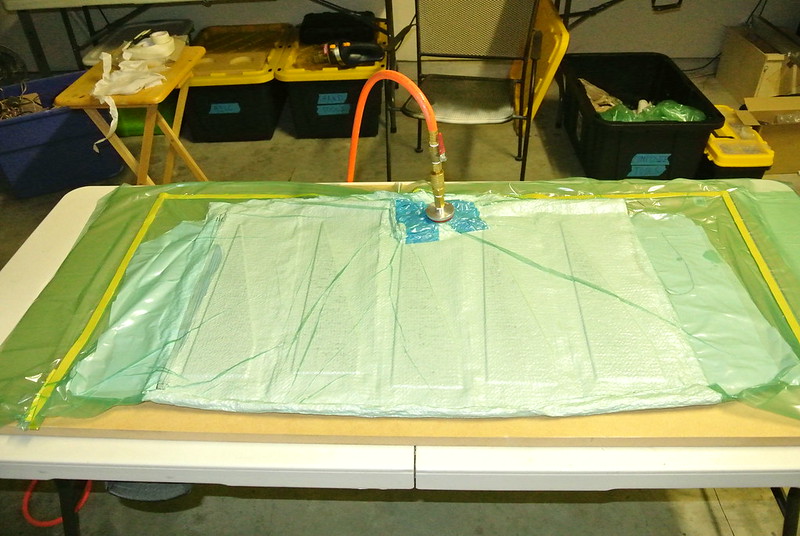

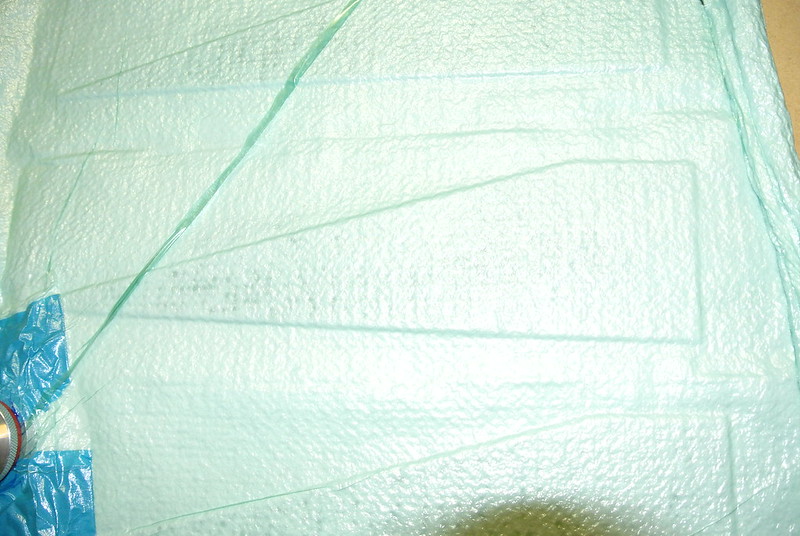

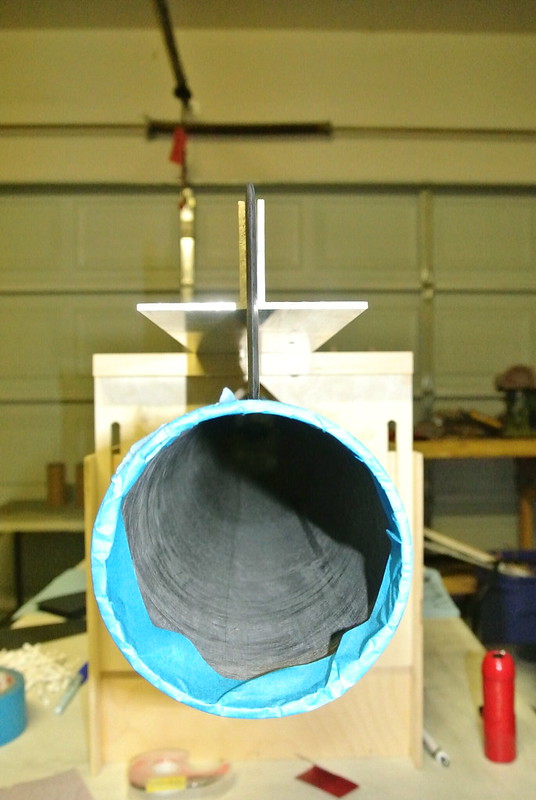

The tip-to-tip was then vacuum bagged for ~6 hours and then the rocket was loaded into a trailer and headed for Gerlach.

On a side note that last picture brings me to a question that I couldn't seem to quite get answered. This is a subject that I have virtually no understanding on. If you notice this is a four fin rocket so there is less space between each fin. The fillets are huge, going up the fin span ~1" and leaving ~2.5" of

just fin left. The addition of 4 layers of carbon cloth further piled onto that. Basically after all said and done the fin area had a lot built up onto it (as can be seen). My question is, if this would alter the air flow across the fins and somehow reduce the fins ability to produce stability?