Working on an osprey at the moment, are there any other ways to anchor kevlar cord without gluing it to the MMT? Smaller U-bolt or eye?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Ideas for shock cord mount, 3in. Airframe with 54mm mmt

- Thread starter Rob702Martinez

- Start date

Help Support The Rocketry Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Eyebolts can fit in tight spaces. You can use a shock cord anchor ahead of the motor or a threaded forward closure and connect right to the motor as well. Though that last option removes motor deployment as an option.

iqsy59

Well-Known Member

- Joined

- Feb 9, 2012

- Messages

- 939

- Reaction score

- 18

I have used a U-bolt through the centering ring for 3" w/54mm mount. The only downside is that I cannot reach to replace the harness using this method.

I remember when I was just a little BAR, one of the forum's resident experts taught me how to replace a shock cord on a paper-tube rocket. CJ, do you remember what you taught me? He suggested that I take some scrap airframe or coupler tube...maybe 6" long. Cut length in half (2 x 3" lengths). If coupler tube, split one of the 3" lengths down the middle and remove just enough material where it will fit inside the other 3" piece as a coupler inside the coupler. Next, he suggested to place the new harness inside the outer coupler tube, cover with epoxy, install the inner coupler tube, loop the shock cord back up into the inside of the inner tube and epoxy in place. That assembly could then be epoxied into the airframe at an appropriate depth.

I thought that was a very simple and elegant solution. This came back to me recently, as I am building a 2.6" w/54 mm mount. There really isn't enough material between the bt and mt to make robust connection. Instructions from the manufacturer suggest only using plugged motors with threaded forward closures to mount shock cord. This is fine, but would limit me in the future to plugged options and I really wanted this kit to be extremely versatile...including flying it without payload section on smaller motors and no electronics.

With that in mind, I would like to pose a question to all. Maybe it could help both the OP and me with additional options. Do you think it would be possible to take CJ's concept, apply it to FG components, and possibly expand on it to make the assembly removable? I was thinking of using t-nuts so that I could slide the assembly into the airframe and hold it in place with 3 screws through the airframe which would give the option of removing it and plugging the mounting holes in the airframe when I wanted to use plugged motors. Are there any solid reasons that you could think of why this would not work?

Cheers,

Michael

I remember when I was just a little BAR, one of the forum's resident experts taught me how to replace a shock cord on a paper-tube rocket. CJ, do you remember what you taught me? He suggested that I take some scrap airframe or coupler tube...maybe 6" long. Cut length in half (2 x 3" lengths). If coupler tube, split one of the 3" lengths down the middle and remove just enough material where it will fit inside the other 3" piece as a coupler inside the coupler. Next, he suggested to place the new harness inside the outer coupler tube, cover with epoxy, install the inner coupler tube, loop the shock cord back up into the inside of the inner tube and epoxy in place. That assembly could then be epoxied into the airframe at an appropriate depth.

I thought that was a very simple and elegant solution. This came back to me recently, as I am building a 2.6" w/54 mm mount. There really isn't enough material between the bt and mt to make robust connection. Instructions from the manufacturer suggest only using plugged motors with threaded forward closures to mount shock cord. This is fine, but would limit me in the future to plugged options and I really wanted this kit to be extremely versatile...including flying it without payload section on smaller motors and no electronics.

With that in mind, I would like to pose a question to all. Maybe it could help both the OP and me with additional options. Do you think it would be possible to take CJ's concept, apply it to FG components, and possibly expand on it to make the assembly removable? I was thinking of using t-nuts so that I could slide the assembly into the airframe and hold it in place with 3 screws through the airframe which would give the option of removing it and plugging the mounting holes in the airframe when I wanted to use plugged motors. Are there any solid reasons that you could think of why this would not work?

Cheers,

Michael

I had Teddy @ one bad hawk, make me up several short pieces of Kevlar with a loop on one end, to attach to the recovery harness, and a stainless welded shut eye-bolt sewn into the other end. I use a double upped forward centering ring to anchor it to. I have this setup on two 3" rockets with a 54mm airframe, my 3" Darkstar and my 3" Pain Killer, that I really need to finish. Here are some pics of the Pain Killer, Darkstar is the same setup.

- Joined

- Jan 11, 2013

- Messages

- 6,450

- Reaction score

- 961

Thank you Michael..

This is exactly the reason I carry the 3/16" welded stainless eyes...

You still have to be careful though because you can't put a quick link on it..

If it's a 54mm mount in a 3" airframe then the link will stop the motor case from coming up past it...

I have one in my rocket "Green Hornet" that doesn't have a piece of Kevlar sewn on it...

I make a piece of the 11/32" Tubular Kevlar with a bigger loop then normal and loop it through the eye..

It's still bulky but the motor case can squish it and get past it no problem...

That rocket has been up for dozens of flights including one of my all time favorite loads--

Aerotech K 375 W for the 54 / 2560 case.. It made about 12.5 K...

Works great no probs...

Teddy

This is exactly the reason I carry the 3/16" welded stainless eyes...

You still have to be careful though because you can't put a quick link on it..

If it's a 54mm mount in a 3" airframe then the link will stop the motor case from coming up past it...

I have one in my rocket "Green Hornet" that doesn't have a piece of Kevlar sewn on it...

I make a piece of the 11/32" Tubular Kevlar with a bigger loop then normal and loop it through the eye..

It's still bulky but the motor case can squish it and get past it no problem...

That rocket has been up for dozens of flights including one of my all time favorite loads--

Aerotech K 375 W for the 54 / 2560 case.. It made about 12.5 K...

Works great no probs...

Teddy

You still have to be careful though because you can't put a quick link on it

You mean you cannot use a quick link directly on the eye-bolt. But obviously you can use the quick-link to connect your harness to the other end of the Kevlar with the loop, which is what I do on my Darkstar, and if I ever finish my Pain Killer I will simply do the same thing. The point being that your completed assembly, as is and used as intended, is a possible solution for this build.

- Joined

- Jan 11, 2013

- Messages

- 6,450

- Reaction score

- 961

You mean you cannot use a quick link directly on the eye-bolt. But obviously you can use the quick-link to connect your harness to the other end of the Kevlar with the loop, which is what I do on my Darkstar, and if I ever finish my Pain Killer I will simply do the same thing. The point being that your completed assembly, as is and used as intended, is a possible solution for this build.

Yep,,

For sure..

There are two configurations this works great for..

A 54 in a 3"..

And a 38 in a 2.6"...

I'm not certain it will fit in a 38 in a 2.1"....

Teddy

blackjack2564

Crazy Jim's Gone Banana's

Reason for not wanting to glue harness to MM?

Got rockets 12yrs old with hundreds of flights and harness still fine.

So much simpler than fighting ill fitting hardware in tiny space.

I've never broke one, but have burnt one to a crisp when front closure blew off.

Just used small section of coupler to make new harness sandwich ....slide into airframe... down onto top of CR. & glue.

I suppose it would be quite simple to make it removable if one desired such.

Got rockets 12yrs old with hundreds of flights and harness still fine.

So much simpler than fighting ill fitting hardware in tiny space.

I've never broke one, but have burnt one to a crisp when front closure blew off.

Just used small section of coupler to make new harness sandwich ....slide into airframe... down onto top of CR. & glue.

I suppose it would be quite simple to make it removable if one desired such.

Last edited:

o1d_dude

'I battle gravity'

Reason for not wanting to glue harness to MM?

Got rockets 12yrs old with hundreds of flights and harness still fine.

So much simpler than fighting ill fitting hardware in tiny space.

I've never broke one, but have burnt one to a crisp when front closure blew off.

Just used small section of coupler to make new harness sandwich ....slide into airframe... down onto top of CR. & glue.

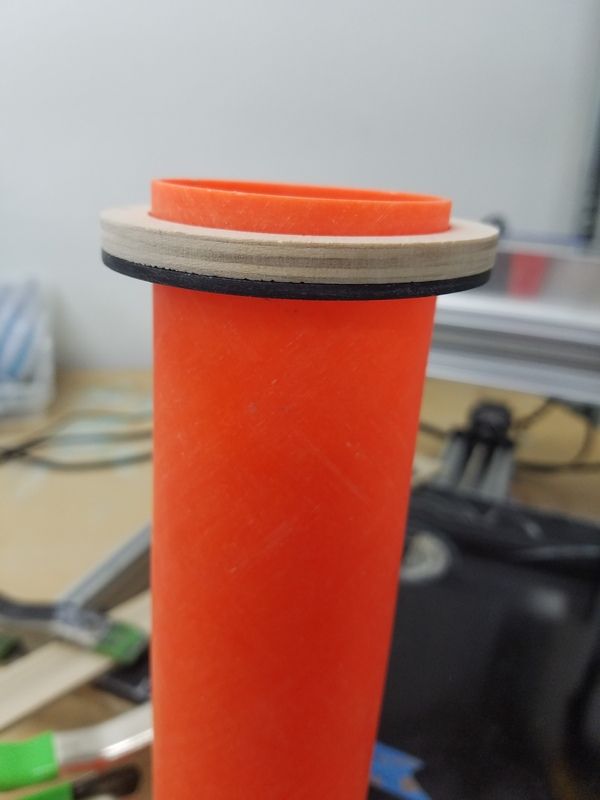

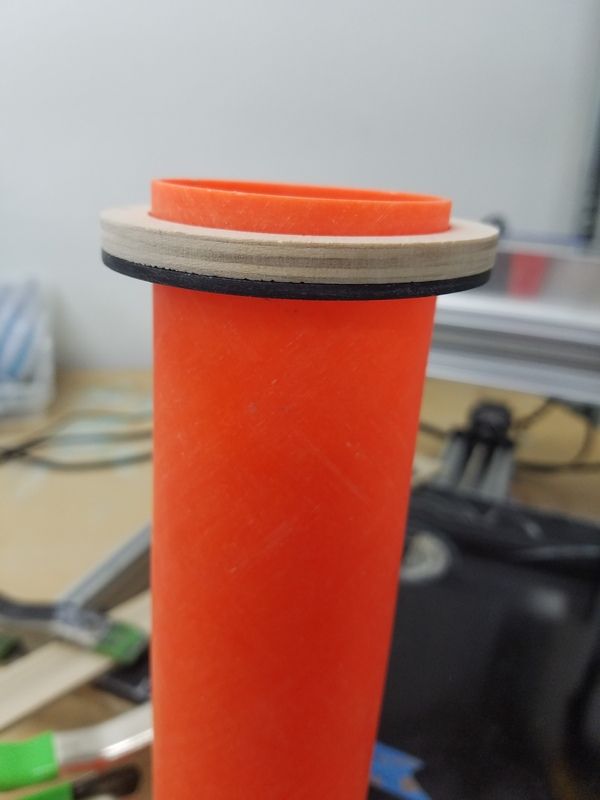

View attachment 320179 View attachment 320180

View attachment 320181

I suppose it would be quite simple to make it removable if one desired such.

Ever since Jim explained to me the Riddle of the Y-Harness, gluing the shock cord to the motor mount is the only method I have used. No hardware needed. Once and done.

- Joined

- Jan 11, 2013

- Messages

- 6,450

- Reaction score

- 961

Reason for not wanting to glue harness to MM?

Got rockets 12yrs old with hundreds of flights and harness still fine.

So much simpler than fighting ill fitting hardware in tiny space.

I've never broke one, but have burnt one to a crisp when front closure blew off.

Just used small section of coupler to make new harness sandwich ....slide into airframe... down onto top of CR. & glue.

View attachment 320179 View attachment 320180

View attachment 320181

I suppose it would be quite simple to make it removable if one desired such.

Maybe your hardware is ill fitting Jim,, I don't know..

Mine most definitely isn't...

When I make up a short attachment harness to a stainless welded polished eye,,

it fit's in this application like it was meant to be there,, perfectly...

( yes, you have to grind a sixteenth or so off both sides of the flat washer)..

My method is neat and clean and looks and works like it was manufactured to be...

If you like your glue method that's fine,, more power to ya..

I like every single aspect of my method better, bar none...

Teddy

Maybe your hardware is ill fitting Jim,, I don't know..

Mine most definitely isn't...

When I make up a short attachment harness to a stainless welded polished eye,,

it fit's in this application like it was meant to be there,, perfectly...

( yes, you have to grind a sixteenth or so off both sides of the flat washer)..

My method is neat and clean and looks and works like it was manufactured to be...

If you like your glue method that's fine,, more power to ya..

I like every single aspect of my method better, bar none...

Teddy

Teddy can you post a pic of your setup?

I'm not as smart as Crazy Jim, but I figure there's no point in using an eyebolt if the body tube is too small for me to reach down in there and undo a quicklink or whatever. For me, this means the rocket has to be at least a stubby 4" rocket or larger. Everything else gets a Y harness against the motor mount tube.

- Joined

- Jul 15, 2015

- Messages

- 3,957

- Reaction score

- 2,714

I'm not as smart as Crazy Jim, but I figure there's no point in using an eyebolt if the body tube is too small for me to reach down in there and undo a quicklink or whatever. For me, this means the rocket has to be at least a stubby 4" rocket or larger. Everything else gets a Y harness against the motor mount tube.

Meh, I could go either way with it. Ever since I bent a piece of music wire to get down a body tube and through an eye deep in there, I haven't had any trouble removing/replacing any of my harnesses. I still glue some in, though.

I bent a piece of music wire to get down a body tube and through an eye deep in there

Your phrasing here.....

o1d_dude

'I battle gravity'

Sounds like there are many paths to rocketry shock cord nirvana.

Follow the path with heart and makes you happy.

Follow the path with heart and makes you happy.

iqsy59

Well-Known Member

- Joined

- Feb 9, 2012

- Messages

- 939

- Reaction score

- 18

Reason for not wanting to glue harness to MM?

Got rockets 12yrs old with hundreds of flights and harness still fine.

So much simpler than fighting ill fitting hardware in tiny space.

I've never broke one, but have burnt one to a crisp when front closure blew off.

Just used small section of coupler to make new harness sandwich ....slide into airframe... down onto top of CR. & glue.

View attachment 320179 View attachment 320180

View attachment 320181

I suppose it would be quite simple to make it removable if one desired such.

Yep...that's the technique to which I was referring above. It is the perfect retrofit solution, in my opinion; simple and elegant.

My reasoning for not gluing harness to MM during the build is because it is a 2.6" airframe and 54 mm MM. The CR is less than 5 mm thick. My only reason for making it possibly removable is to save weight in the "extreme" configuration where I would use a threaded forward closure.

I still remember the first thing you ever taught me...keep it simple...and I try to follow that, but sometimes the engineer in me takes over. You have to remember who I work for. They don't keep anything simple!

Cheers,

Michael

Nytrunner

Pop lugs, not drugs

With that in mind, I would like to pose a question to all. Maybe it could help both the OP and me with additional options. Do you think it would be possible to take CJ's concept, apply it to FG components, and possibly expand on it to make the assembly removable? I was thinking of using t-nuts so that I could slide the assembly into the airframe and hold it in place with 3 screws through the airframe which would give the option of removing it and plugging the mounting holes in the airframe when I wanted to use plugged motors. Are there any solid reasons that you could think of why this would not work?

I like this scheme. I'll have to try it some day. (wonder if rivets would work....)

Sounds like there are many paths to rocketry shock cord nirvana.

Follow the path with heart and makes you happy.

Truth. Some paths just have more people walking on them (and sometimes throwing rocks at the other paths D: )

Tonimus

Well-Known Member

- Joined

- Jul 8, 2014

- Messages

- 1,511

- Reaction score

- 11

Teddy can you post a pic of your setup?

mpitfield already posted excellent pictures of the eye installed in a centering ring. When measured correctly, this is how it should fit in your booster. The quick link should be just below the edge of the booster so that the replaceable part of the harness is what could be abraded.

My reasoning for not gluing harness to MM during the build is because it is a 2.6" airframe and 54 mm MM. The CR is less than 5 mm thick.

Not sure what material you're working with here, but I did this on my wildman 2.6" darkstar (54mm motor mount). It's had some non optimal deployments, been past Mach 1 and 10k feet a few times, and no issues!

- Joined

- Jan 11, 2013

- Messages

- 6,450

- Reaction score

- 961

Oh man,,

Thank you Tony,,

Tim,,

As soon as you posted that I emailed 2 people to give

to give me the measurement from the top CR to the top edge of the booster...

I was going to make 2 of them and take a pic to post,,

but neither of them got back to me yet...

Yep,, that's the idea Tony..

How do you like that set up ??

Teddy

Tony/Teddy - thanks.

Eyebolts can fit in tight spaces. You can use a shock cord anchor ahead of the motor or a threaded forward closure and connect right to the motor as well. Though that last option removes motor deployment as an option.

I dont have any threaded closures yet, but considered it. I will be using 29-54 motors though.

or a u bolt thru the top centering ring (offset so it wouldn't stop a motor tube from being passed by it)

I didnt find one small enough that was suitable or looked like it would hold

I have used a U-bolt through the centering ring for 3" w/54mm mount. The only downside is that I cannot reach to replace the harness using this method.

got a picture of the u-bolt or where you got it?

With that in mind, I would like to pose a question to all. Maybe it could help both the OP and me with additional options. Do you think it would be possible to take CJ's concept, apply it to FG components, and possibly expand on it to make the assembly removable? I was thinking of using t-nuts so that I could slide the assembly into the airframe and hold it in place with 3 screws through the airframe which would give the option of removing it and plugging the mounting holes in the airframe when I wanted to use plugged motors. Are there any solid reasons that you could think of why this would not work?

Cheers,

Michael

View attachment 320178

got a pic of the Ubolt or where did you get it? Also I was just thinking something like that on the way home from work earlier. Maybe a aluminum machined piece with hole(s) for gasses to go through, with 3 screws through the airframe into threads, kinda like how all my nose cones are in my builds..... I like that.. AND the cnc machine works! hmm..

I had Teddy @ one bad hawk, make me up several short pieces of Kevlar with a loop on one end, to attach to the recovery harness, and a stainless welded shut eye-bolt sewn into the other end. I use a double upped forward centering ring to anchor it to. I have this setup on two 3" rockets with a 54mm airframe, my 3" Darkstar and my 3" Pain Killer, that I really need to finish. Here are some pics of the Pain Killer, Darkstar is the same setup.

That is perfect, more importantly i was also looking to see if this setup works, and if anyone has used it (im sure there are tons) and had pics of what they used.

Thank you Michael..

This is exactly the reason I carry the 3/16" welded stainless eyes...

You still have to be careful though because you can't put a quick link on it..

If it's a 54mm mount in a 3" airframe then the link will stop the motor case from coming up past it...

.

Teddy

Right, I wouldn't use a quick link rather the cord looped to the eye. I believe I have one somewhere. I'll have to look now for it.

Yep,,

For sure..

There are two configurations this works great for..

A 54 in a 3"..

And a 38 in a 2.6"...

I'm not certain it will fit in a 38 in a 2.1"....

Teddy

I squeezed a small welded eye into a wildman punisher ss our local hardware place had some.

Reason for not wanting to glue harness to MM?

I have a mental block that gluing my kevlar cord to my MMT is going to hold. I know it does, people have been doing it forever etc. I need a mechanical connection to feel safe when I push the button, its more of a personal thing, even though this is way easier and works just as well.

thank you all for your replies! I managed to find a few welded eyes from OBH in my garage, and seeing that it works for others helps.

I cut a 1/4 ply CR doubler for more surface area for epoxy and for the bolt just need to measure it out.

here is what im working with as of now.

I think this should be OK, after I fly this a few times I intend to build a small booster section to turn this into a 2 stage at some point.

I cut a 1/4 ply CR doubler for more surface area for epoxy and for the bolt just need to measure it out.

here is what im working with as of now.

I think this should be OK, after I fly this a few times I intend to build a small booster section to turn this into a 2 stage at some point.

woferry

Well-Known Member

Heh. I'm also working on a 2-stage Osprey, I built one last year but it came in ballistic at XPRS in September (forgot the proper procedure to arm a TRS for flight  ). The nose, AVbay and top 8" of the airframe were destroyed, but the fin-can came out fine. The replacement bits to turn what's left back into a full rocket would have cost as much as a full kit, so I opted for the kit. But I've notched the fin roots and will build the new kit to be a sustainer, just needing another coupler/vent band to use what's left of the first rocket as a booster. I suspect I'll epoxy a short harness to my MMT just as I did the first time around, I don't see any benefit to having an eye-bolt that I'd never be able to reach anyway.

). The nose, AVbay and top 8" of the airframe were destroyed, but the fin-can came out fine. The replacement bits to turn what's left back into a full rocket would have cost as much as a full kit, so I opted for the kit. But I've notched the fin roots and will build the new kit to be a sustainer, just needing another coupler/vent band to use what's left of the first rocket as a booster. I suspect I'll epoxy a short harness to my MMT just as I did the first time around, I don't see any benefit to having an eye-bolt that I'd never be able to reach anyway.

). The nose, AVbay and top 8" of the airframe were destroyed, but the fin-can came out fine. The replacement bits to turn what's left back into a full rocket would have cost as much as a full kit, so I opted for the kit. But I've notched the fin roots and will build the new kit to be a sustainer, just needing another coupler/vent band to use what's left of the first rocket as a booster. I suspect I'll epoxy a short harness to my MMT just as I did the first time around, I don't see any benefit to having an eye-bolt that I'd never be able to reach anyway.

). The nose, AVbay and top 8" of the airframe were destroyed, but the fin-can came out fine. The replacement bits to turn what's left back into a full rocket would have cost as much as a full kit, so I opted for the kit. But I've notched the fin roots and will build the new kit to be a sustainer, just needing another coupler/vent band to use what's left of the first rocket as a booster. I suspect I'll epoxy a short harness to my MMT just as I did the first time around, I don't see any benefit to having an eye-bolt that I'd never be able to reach anyway.Tonimus

Well-Known Member

- Joined

- Jul 8, 2014

- Messages

- 1,511

- Reaction score

- 11

Oh man,,

Thank you Tony,,

Tim,,

As soon as you posted that I emailed 2 people to give

to give me the measurement from the top CR to the top edge of the booster...

I was going to make 2 of them and take a pic to post,,

but neither of them got back to me yet...

Yep,, that's the idea Tony..

How do you like that set up ??

Teddy

Love it. I've had zero issues with it. And considering that the booster with the empty motor casing is almost the lightest part of the rocket, I'm sure it'll last a good long time.

Wow!

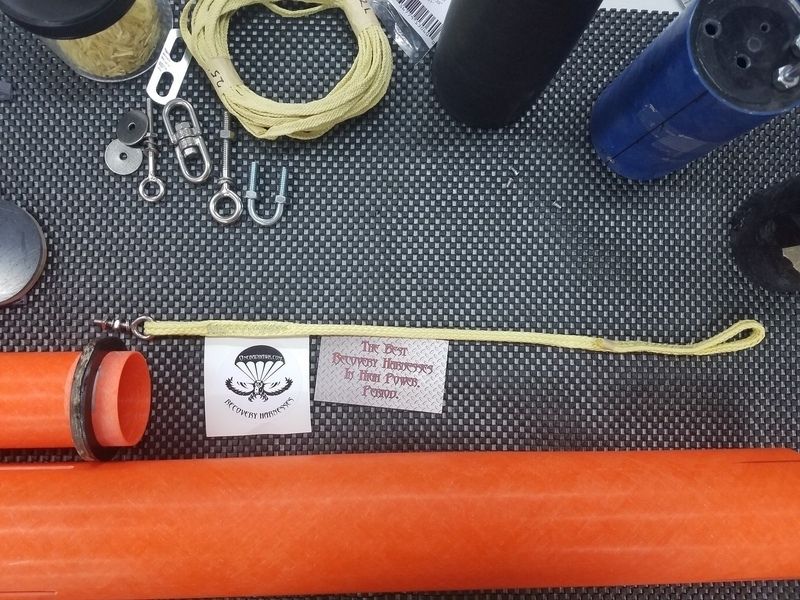

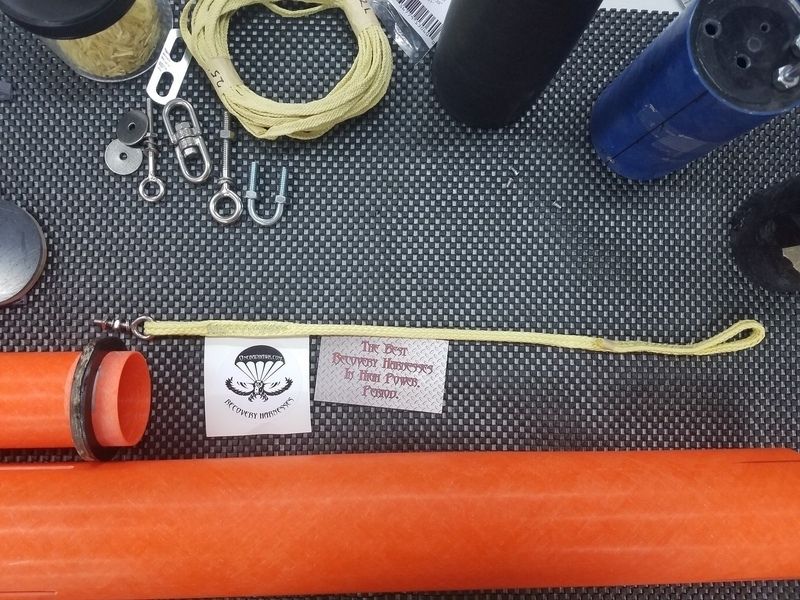

Wow you guys! I posted this on Tuesday Night, and look what showed up in the mail TODAY! :surprised:

Teddy right away reached out to ME, asked for the length from top CR to air frame opening. 2 Loops sewn to a 3/16 polished ss welded eye. 19 inches long. Outstanding support from OneBadHawk, not only just right here and every purchase, Teddy takes time to be involved with his product and also supports Tripoli Vegas during SpringFest and OctoberFest.

I appreciate it Teddy, and this is what makes this hobby awesome!

Build to follow soon, now that I have my solution, and how quick and easy it was to get it. It fits perfect, going forward will most likely use this method. Measure from the top of the CR to the AF opening. Boom!

Check it out.

Wow you guys! I posted this on Tuesday Night, and look what showed up in the mail TODAY! :surprised:

Teddy right away reached out to ME, asked for the length from top CR to air frame opening. 2 Loops sewn to a 3/16 polished ss welded eye. 19 inches long. Outstanding support from OneBadHawk, not only just right here and every purchase, Teddy takes time to be involved with his product and also supports Tripoli Vegas during SpringFest and OctoberFest.

I appreciate it Teddy, and this is what makes this hobby awesome!

Build to follow soon, now that I have my solution, and how quick and easy it was to get it. It fits perfect, going forward will most likely use this method. Measure from the top of the CR to the AF opening. Boom!

Check it out.

Last edited:

o1d_dude

'I battle gravity'

Teddy is the man.

Similar threads

- Replies

- 6

- Views

- 485