StefanJ

Well-Known Member

- Joined

- Jul 6, 2009

- Messages

- 428

- Reaction score

- 5

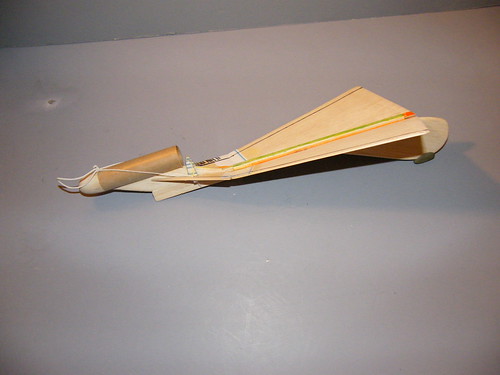

I just finished building and trimming a "Raven," a nifty delta-winged boost glider from an old Model Rocket News plan:

https://www.spacemodeling.org/JimZ/eirp_23.htm

I just reread the plans to see if I needed to do anything else. I notice that they call for the area to the rear of the motor to be coated with "high heat aluminum paint."

I remember seeing this paint in very old Estes catalogs. Centuri offered a heat proofing solution as well.

I think I could make fireproofing solution from boric acid and borax, but can anyone recommend a modern equivalent of the paint?

I'll post pictures of the Raven on the gallery section.

https://www.spacemodeling.org/JimZ/eirp_23.htm

I just reread the plans to see if I needed to do anything else. I notice that they call for the area to the rear of the motor to be coated with "high heat aluminum paint."

I remember seeing this paint in very old Estes catalogs. Centuri offered a heat proofing solution as well.

I think I could make fireproofing solution from boric acid and borax, but can anyone recommend a modern equivalent of the paint?

I'll post pictures of the Raven on the gallery section.