When I first saw the Star Orbiter on the Estes "Coming soon" page I knew I had to get it, three to be precise.

It reminded me a little of the old Estes Renegade #1271 with the red and black color scheme.

My present scratch built rockets have the same colors. I have found that this combo is easiest to see in the sky and on the ground.

I haven't seen a build thread of this rocket so I thought I'd post one.

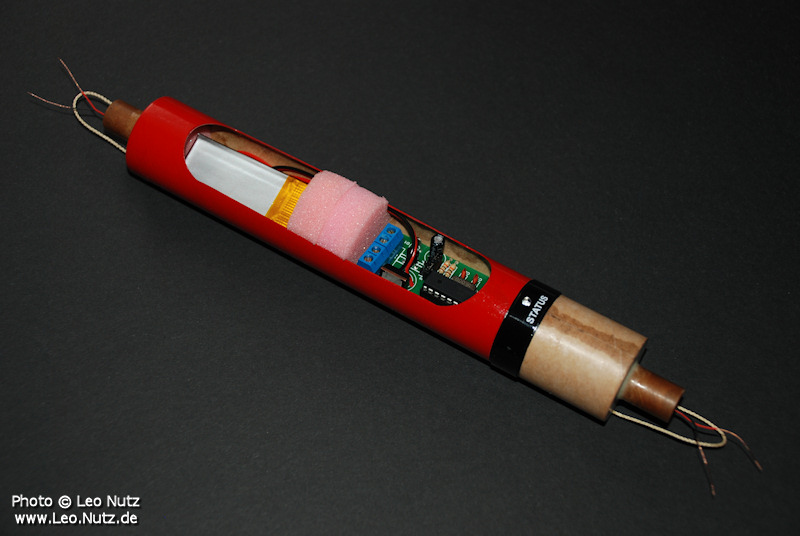

My version will be built as dual deploy and have a compartment for GPS tracker.

It will also be flown for the most part on CTI 29 1-3 grain reloads and maybe on some occasions with Estes F engines.

This rocket will also be my workhorse next to my Estes Ascender dual deploy 2-Stage when I'm flying rockets in the USA.

This thread will also document the flights.

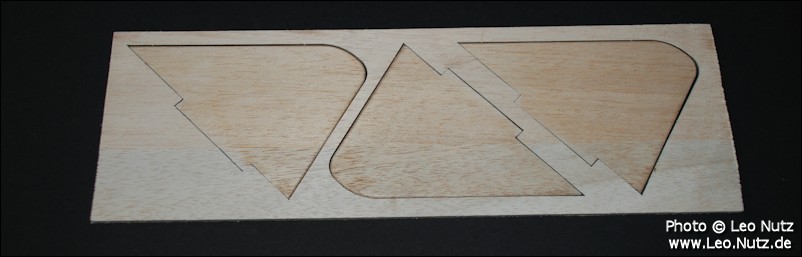

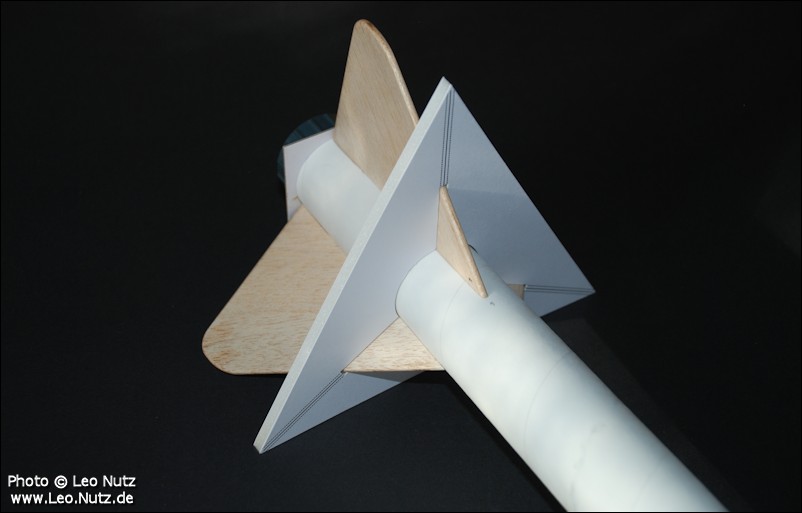

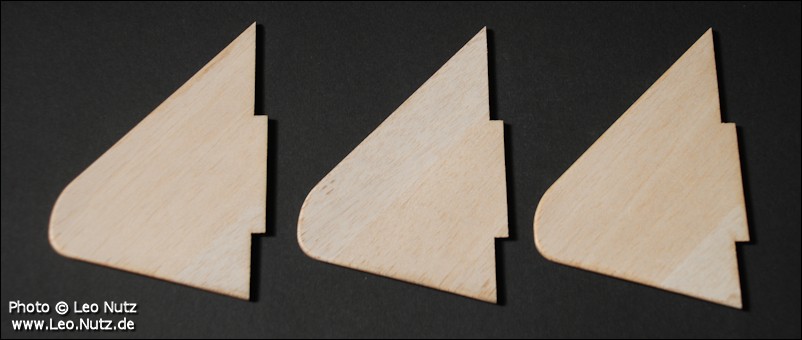

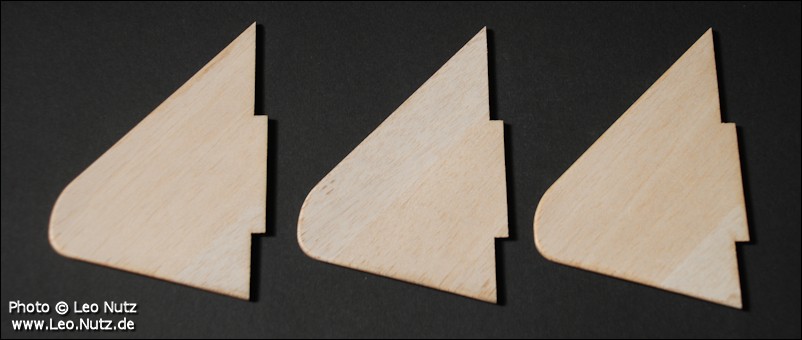

I started off by sanding the fins and rounding the leading edges. They were also strengthened with CA glue:

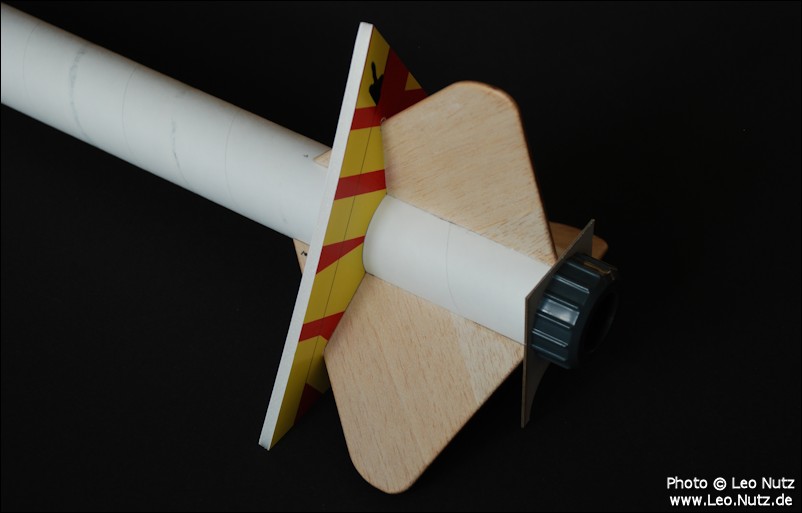

I assembled the engine mounted with epoxy and slightly deviated from the plans concerning parts placements.

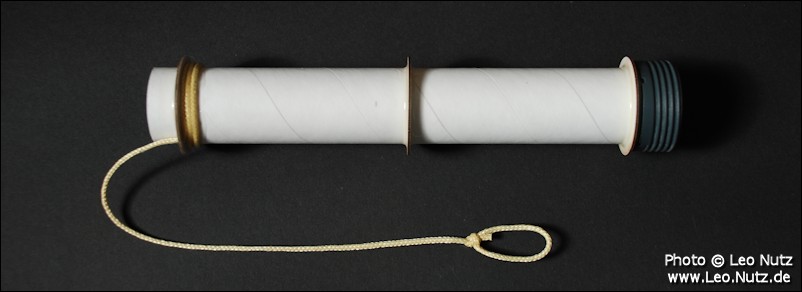

Since I'm not going to use the Estes trifold shock cord holder I went and mounted a Kevlar shock cord to the engine mount:

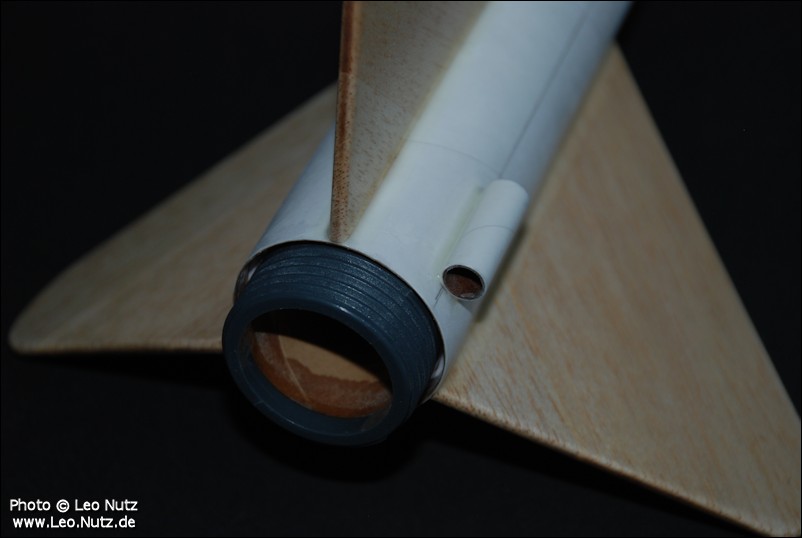

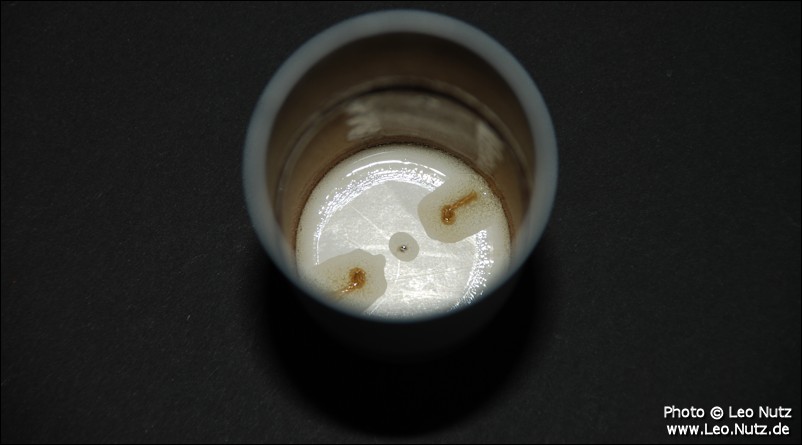

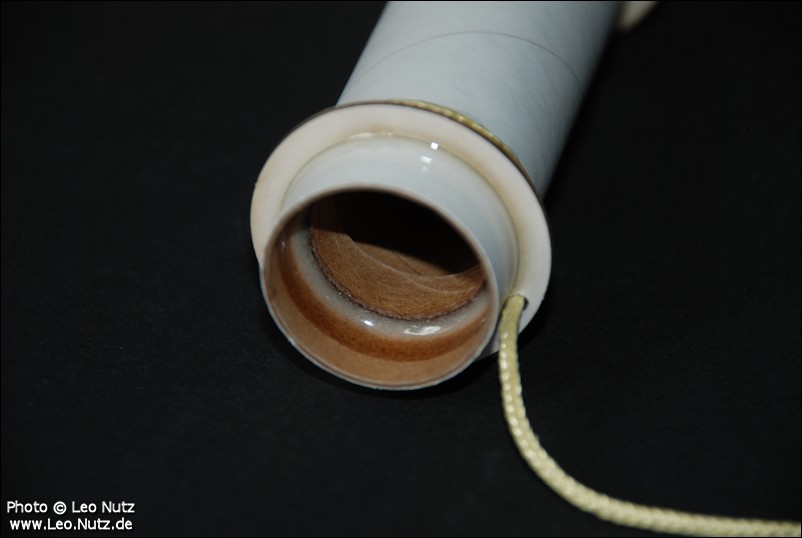

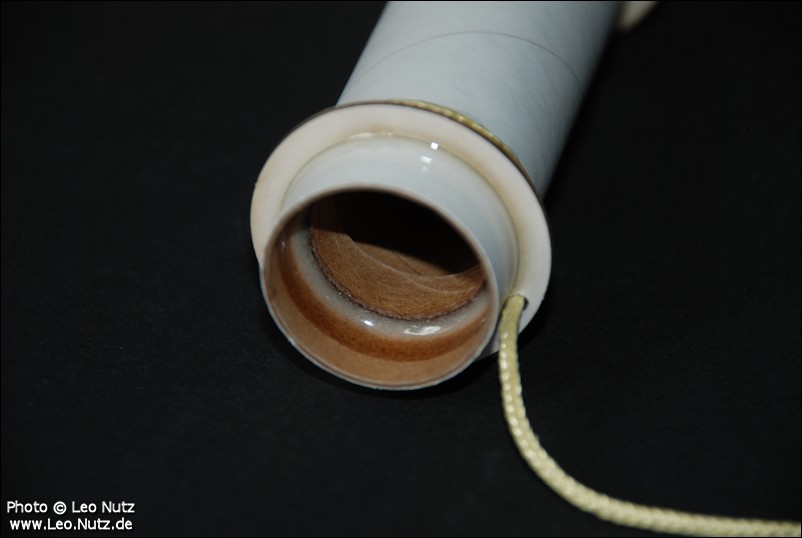

I don't understand why Estes didn't provide an engine block with the kit so I made my own:

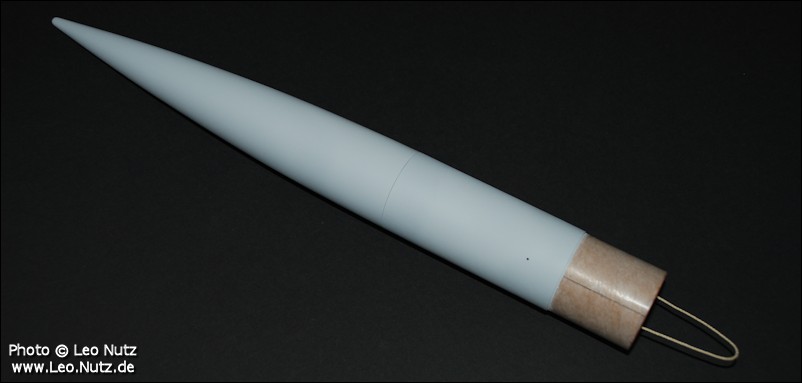

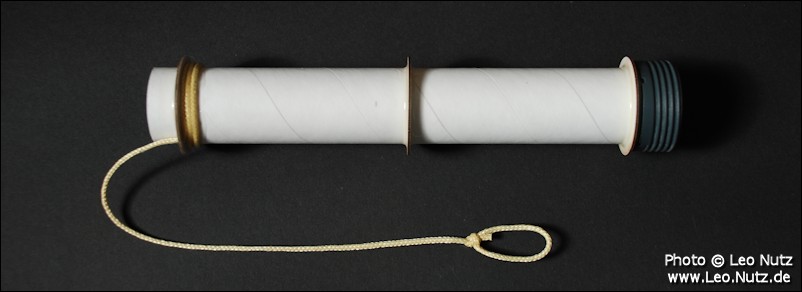

The completed engine mount was then glued inside the lower body tube:

End of part one.

It reminded me a little of the old Estes Renegade #1271 with the red and black color scheme.

My present scratch built rockets have the same colors. I have found that this combo is easiest to see in the sky and on the ground.

I haven't seen a build thread of this rocket so I thought I'd post one.

My version will be built as dual deploy and have a compartment for GPS tracker.

It will also be flown for the most part on CTI 29 1-3 grain reloads and maybe on some occasions with Estes F engines.

This rocket will also be my workhorse next to my Estes Ascender dual deploy 2-Stage when I'm flying rockets in the USA.

This thread will also document the flights.

I started off by sanding the fins and rounding the leading edges. They were also strengthened with CA glue:

I assembled the engine mounted with epoxy and slightly deviated from the plans concerning parts placements.

Since I'm not going to use the Estes trifold shock cord holder I went and mounted a Kevlar shock cord to the engine mount:

I don't understand why Estes didn't provide an engine block with the kit so I made my own:

The completed engine mount was then glued inside the lower body tube:

End of part one.