RocketHunter

Well-Known Member

- Joined

- Jun 15, 2013

- Messages

- 390

- Reaction score

- 3

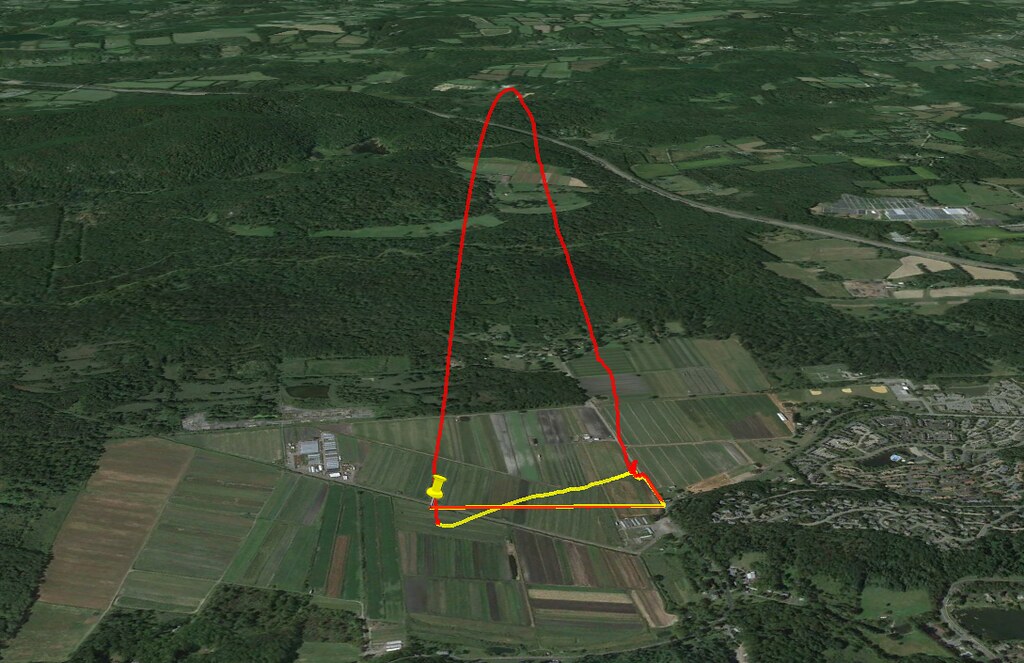

For a while now I have been looking into options for a fiberglass rocket that is both very durable but still light/efficient enough to get close to our 5,000' waiver on level 1 motors. With crops and large ditches, our field is not exactly ideal, so tracking and dual-deploy is a must.

For a while, I considered scratch-building my own 54mm rocket with a 38mm hole, or converting a formula 54 to dual deploy and 38mm MMT. Both these options, however, ended up being pretty costly after I factored in the parts necessary to make the conversions, along with recovery components which are not included in the kit. FWFG is not cheap!

I then, at first just for fun, looked at the wildman blackhawk 38. It is a bit of an extreme performer, but with a slimline retainer on the back and the added weight of dual deploy and tracking, openrocket predicts it will stay under 5,000' on small-to mid I's, and comfortably reach 1-2,000 on midsize H motors. Being fiberglass, durability of course is superb. What really pushed me into buying it was the completeness of the kit - kevlar shock cord, parachute, av-bay lids, beveled fins, fin guides, proline epoxy for gluing everything, and filament wound everything. Assembling these parts individually not only would have taken much more work, but cost much more as well. It really is a great kit.

Everything laid out. The beveled fins are a work of art, super strong too at an 1/8''.

With the fin guides, attaching the fins all at once is as easy as pie, and they are guaranteed to be perfectly straight. After roughing up the body tube and fins with 80 grit sandpaper, I cleaned them off with acetone and glued the fins on with the included proline. I wrapped a rubber band around the fins to hold them all securely down at once, and it worked well.

Next up was fillets. I absolutely love the Proline for doing fillets. The thick, gloopy epoxy pulls out and settles into a nice fillet surprisingly easily, yet holds its position and never drips. Additionally, it dries very quickly, solidifying enough to move on to the next set of fillets in under two hours, meaning it is easy to get all three sets done in a single day.

All taped up, I used a 3/4'' tube to form the fillet radius.

I pull the tape off immediately after shaping the fillet, as the small edge left by the tape then settles down on its own and you're left with a very smooth edge.

I will be deviating from the build instructions in two ways, First, I am going to try doing a tip-to-tip layup with 3k twill carbon fiber and aeropoxy laminating resin. The extra strength is completely unnecessary, but it is a skill I would like to learn. Second, I am going to be trying a unique av-bay design to hopefully allow me to accommodate an AIM XTRA for GPS tracking and dual deployment duties, along with either an AIM USB or RRC2+ for backup. More on that later.

For a while, I considered scratch-building my own 54mm rocket with a 38mm hole, or converting a formula 54 to dual deploy and 38mm MMT. Both these options, however, ended up being pretty costly after I factored in the parts necessary to make the conversions, along with recovery components which are not included in the kit. FWFG is not cheap!

I then, at first just for fun, looked at the wildman blackhawk 38. It is a bit of an extreme performer, but with a slimline retainer on the back and the added weight of dual deploy and tracking, openrocket predicts it will stay under 5,000' on small-to mid I's, and comfortably reach 1-2,000 on midsize H motors. Being fiberglass, durability of course is superb. What really pushed me into buying it was the completeness of the kit - kevlar shock cord, parachute, av-bay lids, beveled fins, fin guides, proline epoxy for gluing everything, and filament wound everything. Assembling these parts individually not only would have taken much more work, but cost much more as well. It really is a great kit.

Everything laid out. The beveled fins are a work of art, super strong too at an 1/8''.

With the fin guides, attaching the fins all at once is as easy as pie, and they are guaranteed to be perfectly straight. After roughing up the body tube and fins with 80 grit sandpaper, I cleaned them off with acetone and glued the fins on with the included proline. I wrapped a rubber band around the fins to hold them all securely down at once, and it worked well.

Next up was fillets. I absolutely love the Proline for doing fillets. The thick, gloopy epoxy pulls out and settles into a nice fillet surprisingly easily, yet holds its position and never drips. Additionally, it dries very quickly, solidifying enough to move on to the next set of fillets in under two hours, meaning it is easy to get all three sets done in a single day.

All taped up, I used a 3/4'' tube to form the fillet radius.

I pull the tape off immediately after shaping the fillet, as the small edge left by the tape then settles down on its own and you're left with a very smooth edge.

I will be deviating from the build instructions in two ways, First, I am going to try doing a tip-to-tip layup with 3k twill carbon fiber and aeropoxy laminating resin. The extra strength is completely unnecessary, but it is a skill I would like to learn. Second, I am going to be trying a unique av-bay design to hopefully allow me to accommodate an AIM XTRA for GPS tracking and dual deployment duties, along with either an AIM USB or RRC2+ for backup. More on that later.

Skipping to the ending, here it is, nearly 100% complete and painted:

Skipping to the ending, here it is, nearly 100% complete and painted: