ECayemberg

Well-Known Member

- Joined

- Jan 21, 2009

- Messages

- 2,877

- Reaction score

- 849

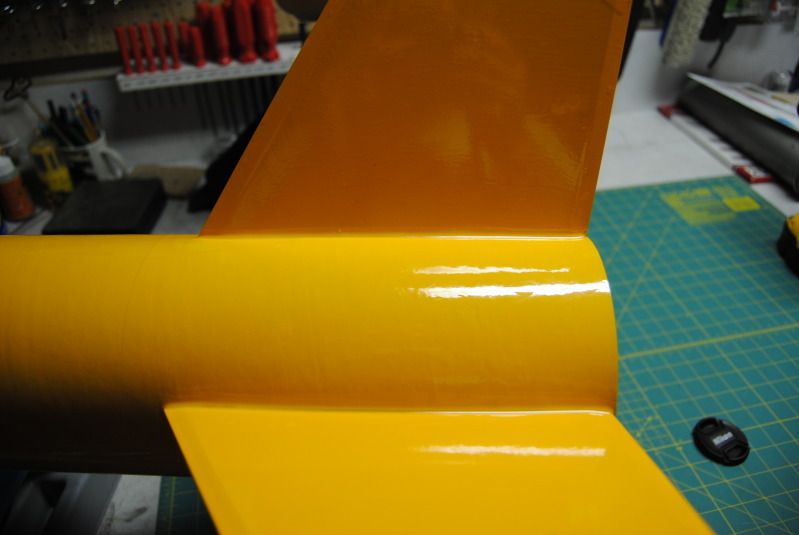

Prelude: I knew after seeing Loc's newest kit, the Big Cletus, that I had to have one! Love 5.5" Loc airframe, love the Loc PNC-5.38L, and love Magnum style fins. After Mark posted in his Warlock thread that the Cletus was available, a phone call to Loc took care of my want. Like the other cardboard rockets I build in the winter, this one will again be covered in heat shrink film; namely Ultracote/Oracover, Ultracote Supreme (ie: supremely clearance priced), and Black Monokote for one fin. Mark aka Stickershock23 provided the decals. This build will be very quick, very simple, and hopefully enjoyable. Speak up if I go too fast or mess up along the way!

Initially, I had full intentions of building the rocket completely stock; as Loc now provides most notably: a generous length of tubular nylon recovery harness, rail buttons, and a quality chute. The stock kit is somewhere in between a Minie Magg and an I-roc; 47" in length, 38mm mount, and 1/4" aircraft ply fins. However, fate intervened and I was "forced" to modify the stock kit just a bit.

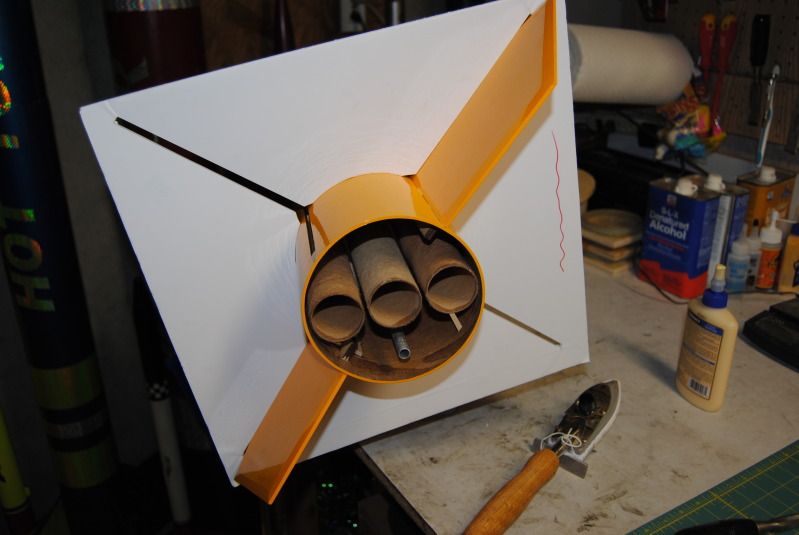

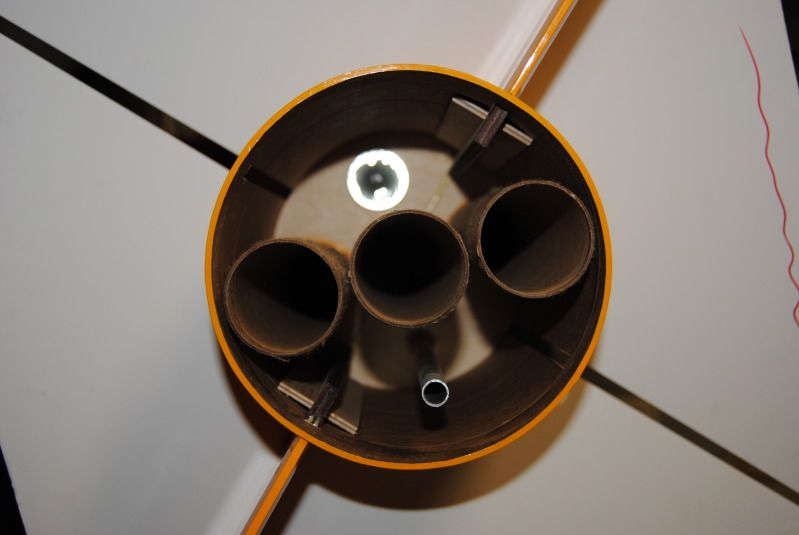

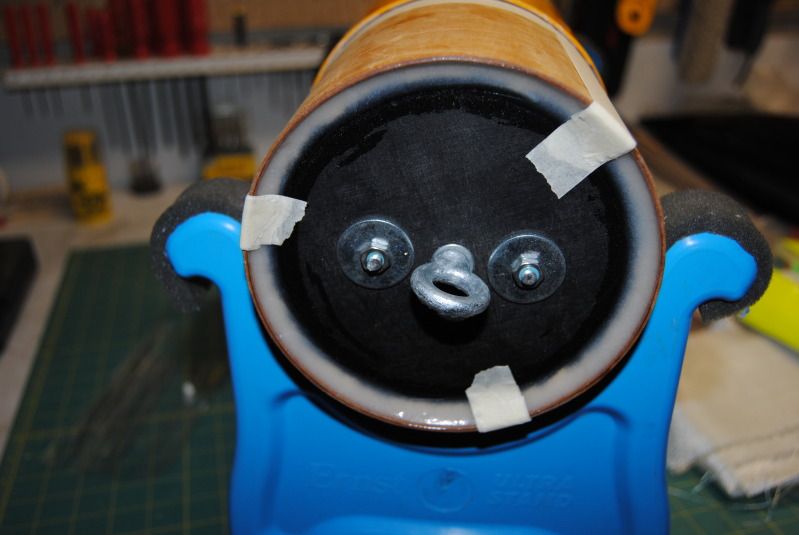

Discoveries: the Big Cletus arrived dressed nicely in the heavy duty box, standard for the several 5.5" airframe orders I've placed in recent years. Upon unboxing, I was surprised to find an "extra" 15" length of 38mm motor mount included: fate moment #1. Within a few days of the Cletus arriving, Justin generously provided me with a grab bag of goodies; upon unboxing the goodies, I discovered several centering rings cut for 5.5" airframe, and holding a trio of 38mm mounts in line: fate moment #2. Upon inspecting the fins, it dawned on me that these fins not only look a lot like Loc Magnum fins (one of my faves), but they also closely resemble the Estes #K-55/1255 Goblin fins. Checking a few dimensions, I discovered I'd need an additonal 13" of 5.5" airframe and a corresponding coupler to arrive at the correct 60" upscaled length of the Gobling. As fate had it, I have a 14" length of airframe and a coupler on hand. I'd be a fool to ignore all these signs; therefore the project quickly transformed into a 3*38mm equipped 4.19X upscale of the classic Goblin.

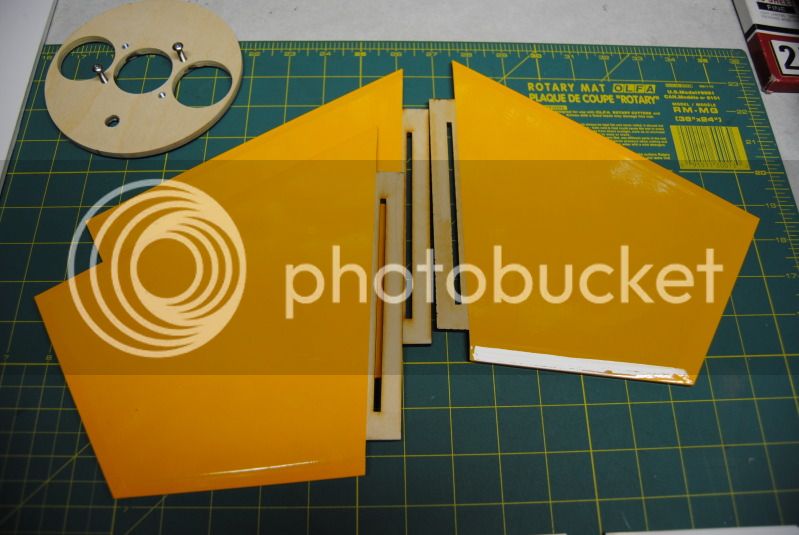

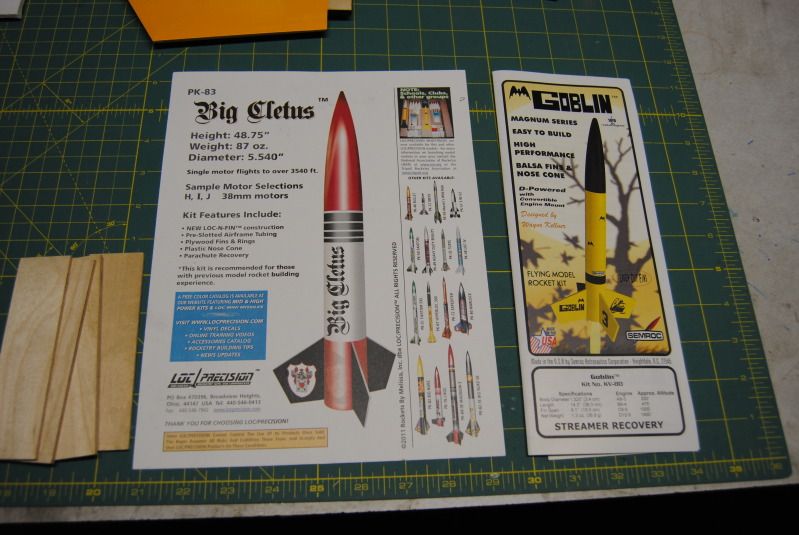

Thus, we have the parts on the table: on the middle and right are the stock components; on the left the extra airframe, coupler, centering rings, and a Semroc Goblin for inspiration:

It should be noted that some new features were present in this kit, namely laser cut fin slots and fins. Quality stuff!

-Eric-

Initially, I had full intentions of building the rocket completely stock; as Loc now provides most notably: a generous length of tubular nylon recovery harness, rail buttons, and a quality chute. The stock kit is somewhere in between a Minie Magg and an I-roc; 47" in length, 38mm mount, and 1/4" aircraft ply fins. However, fate intervened and I was "forced" to modify the stock kit just a bit.

Discoveries: the Big Cletus arrived dressed nicely in the heavy duty box, standard for the several 5.5" airframe orders I've placed in recent years. Upon unboxing, I was surprised to find an "extra" 15" length of 38mm motor mount included: fate moment #1. Within a few days of the Cletus arriving, Justin generously provided me with a grab bag of goodies; upon unboxing the goodies, I discovered several centering rings cut for 5.5" airframe, and holding a trio of 38mm mounts in line: fate moment #2. Upon inspecting the fins, it dawned on me that these fins not only look a lot like Loc Magnum fins (one of my faves), but they also closely resemble the Estes #K-55/1255 Goblin fins. Checking a few dimensions, I discovered I'd need an additonal 13" of 5.5" airframe and a corresponding coupler to arrive at the correct 60" upscaled length of the Gobling. As fate had it, I have a 14" length of airframe and a coupler on hand. I'd be a fool to ignore all these signs; therefore the project quickly transformed into a 3*38mm equipped 4.19X upscale of the classic Goblin.

Thus, we have the parts on the table: on the middle and right are the stock components; on the left the extra airframe, coupler, centering rings, and a Semroc Goblin for inspiration:

It should be noted that some new features were present in this kit, namely laser cut fin slots and fins. Quality stuff!

-Eric-