- Joined

- Dec 7, 2009

- Messages

- 3,554

- Reaction score

- 2,811

I saw one of the new long burn Aerotec's motors a couple of weeks ago,

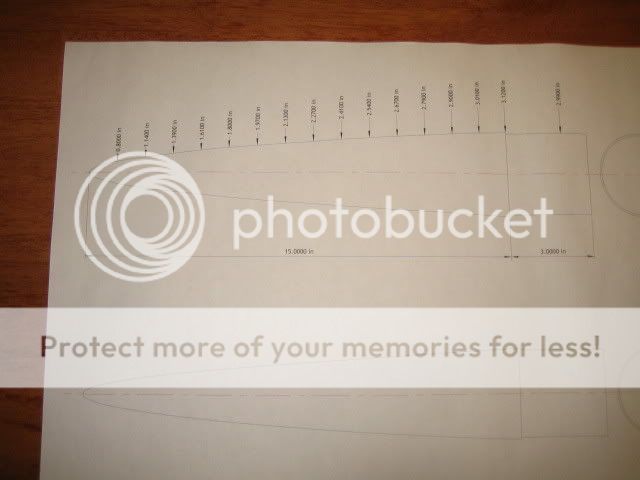

75mm M650, and was able to order one. So now I need to build something special for it. The plan is to make a 3" rocket the same way I did my 54mm min dia rocket https://www.rocketryforum.com/showthread.php?t=23810

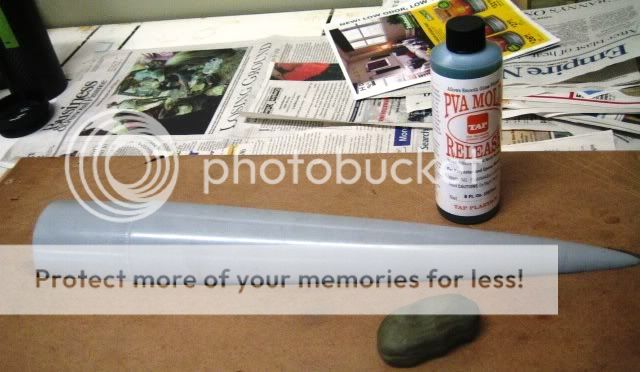

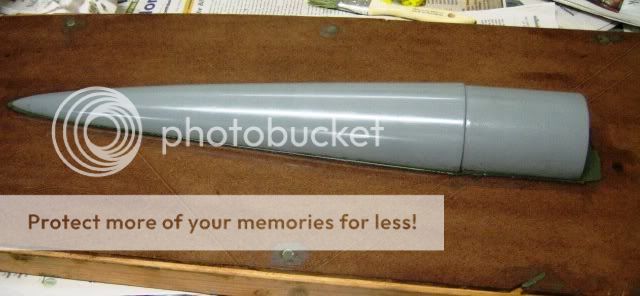

I'm strating on the first of 2 tube layups today. I'm going with 5 wraps of 5.7 oz carbon. The rocket should be about 64" long when done. If there is any step, that was not clear, in the 54mm build thread that you want to see or know more about let me know.

Tony

75mm M650, and was able to order one. So now I need to build something special for it. The plan is to make a 3" rocket the same way I did my 54mm min dia rocket https://www.rocketryforum.com/showthread.php?t=23810

I'm strating on the first of 2 tube layups today. I'm going with 5 wraps of 5.7 oz carbon. The rocket should be about 64" long when done. If there is any step, that was not clear, in the 54mm build thread that you want to see or know more about let me know.

Tony