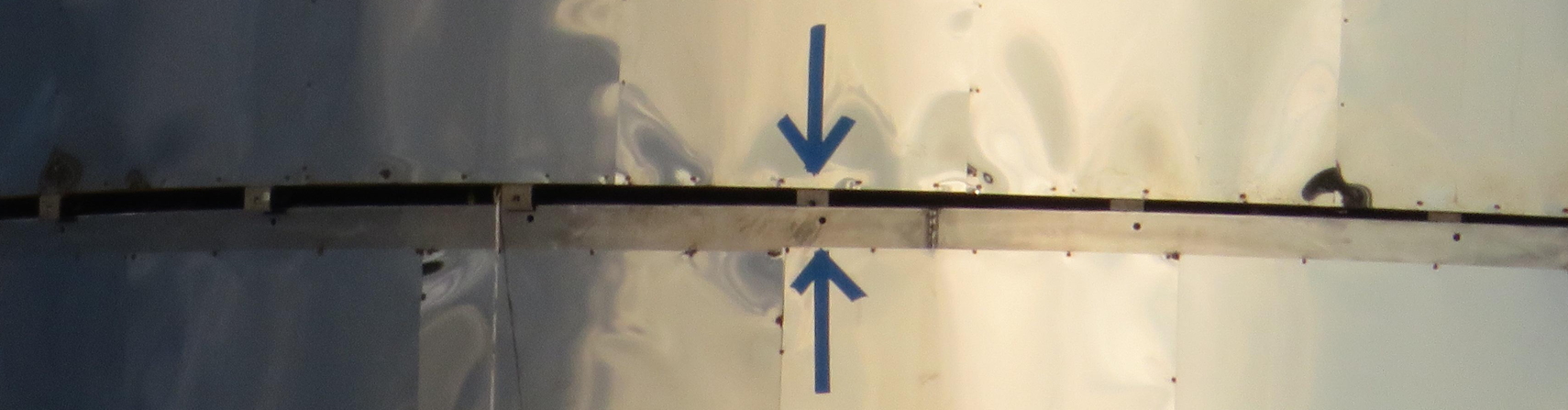

Really close call on fairing catch test:

https://twitter.com/SpaceX/status/1082469132291923968

Tony

screen shot:

https://twitter.com/SpaceX/status/1082469132291923968

Tony

screen shot:

Yeah, it's photoshopped. Look at the lack of reflections on the base of the stand, not to mention the color. But still funny.I am not sure if this is photoshopped, but it is from Elon's twitter, and I would not put it past him to actually have this sign there

Really close call on fairing catch test:

https://twitter.com/SpaceX/status/1082469132291923968

Tony

screen shot:

View attachment 370985

Yeah, it's photoshopped. Look at the lack of reflections on the base of the stand, not to mention the color. But still funny.

Tony

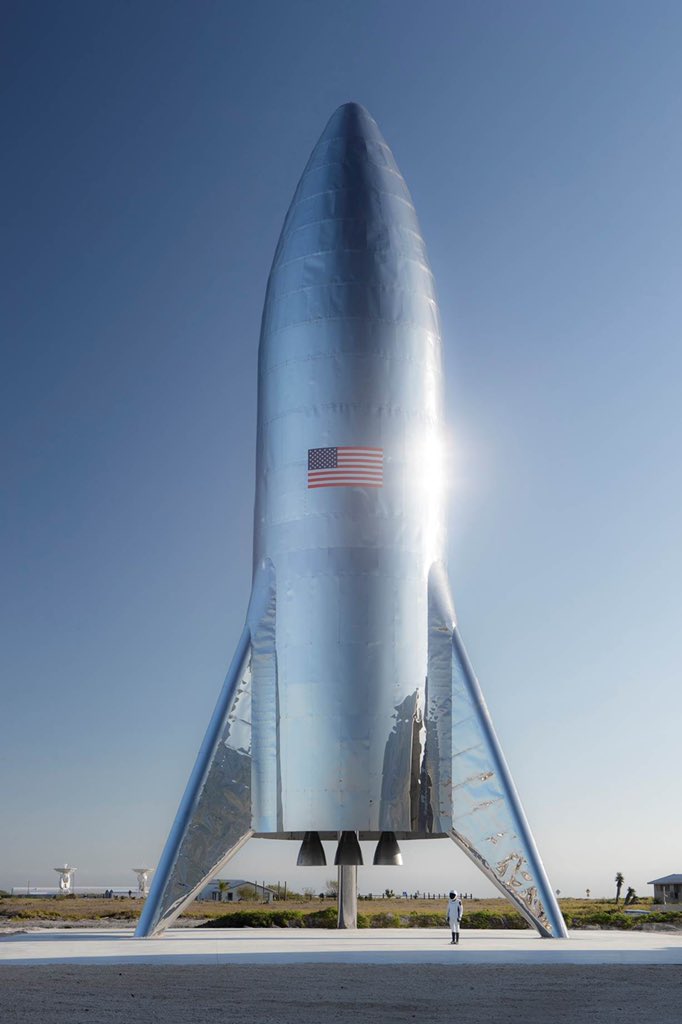

They'll need to improve manufacturing processes to get a perfectly smooth and shiny surface like the renderings. I'm sure that's in process, but it's a lot of work. I'd be curious HOW they intend to do that, since mechanical fasteners (as shown here) obviously have issues and welding tends to distort very thin sheet like this. Maybe the real Starship sheeting will be thicker?

I'm also curious how much work will be needed to return the surface to its mirror finish after a flight. Every time I've gotten stainless really hot, it's turned all sorts of fun colors. If they have to polish/buff that out, it'll be a turnaround nightmare.

Realize that this "hopper" is NOT built like the real BFS/Starship will be built. After all, the main body was literally built by a Water Tank construction company. ...

Oh, some other work being dome. I mean, done.

I saw another pic where those brown-ish rectangular things turned out to be attachment points for a curved ladder.

...

They have radically changed the design from using composites to "heavy metal" (A special alloy of stainless steel). Composite tanks are gone.I thought we’ve already seen pictures of composite tanks of this size being floated out to sea for full scale pressure testing. I sort of assumed they’d drop those tanks inside the Test Big Elon Daddy.

The announcer mentioned that they didn't have a parachute on the fairing so they wouldn't even try to catch the fairing this time. Probably was already planned that way before the near catch earlier this week.

West coast only. They won't need any other ships until and unless they work out how to catch the fairings reliably. Have to admit that upon seeing the video of the "close call", I was unimpressed at the crudeness they are apparently using for this. "Mr Steven" had to make a near 90 degree turn, shortly before trying to catch the fairing, indicates they may not be doing very much automation-enhanced or computer-asssited coordination. If it's all manual, no wonder they haven't caught anything.Do they have a "Mr. Steven" out west? Or is Mr. Steven west only and that's where they do their attempts?

Enter your email address to join: