Holy Balls, it's September! Time for another quick update; telling the story with more photos and few words.

This past week the bulk of work needed to make the two stager ready was completed with a slight sigh of relief. I do need to complete a bit of work on the transition and upper booster airframe however.

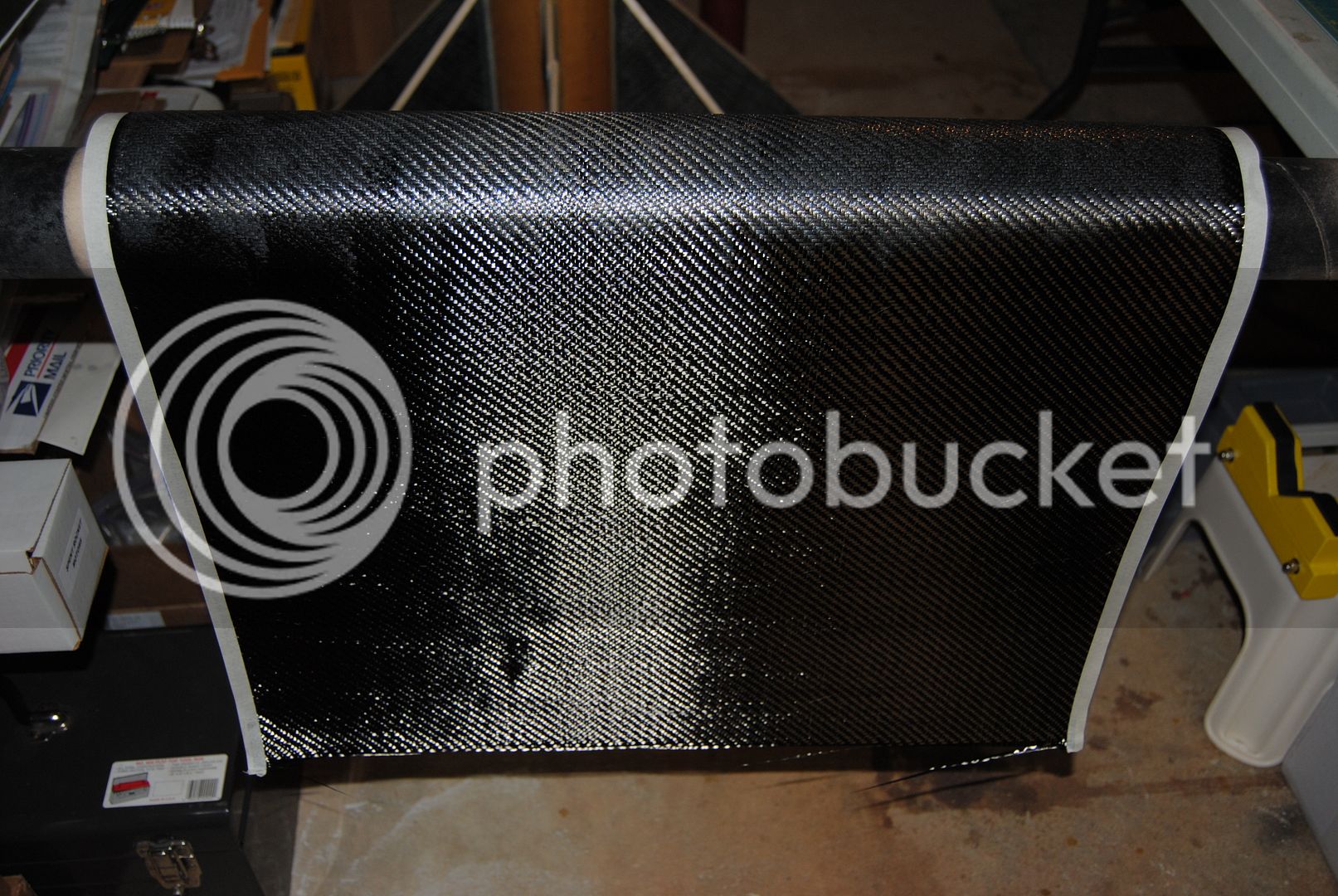

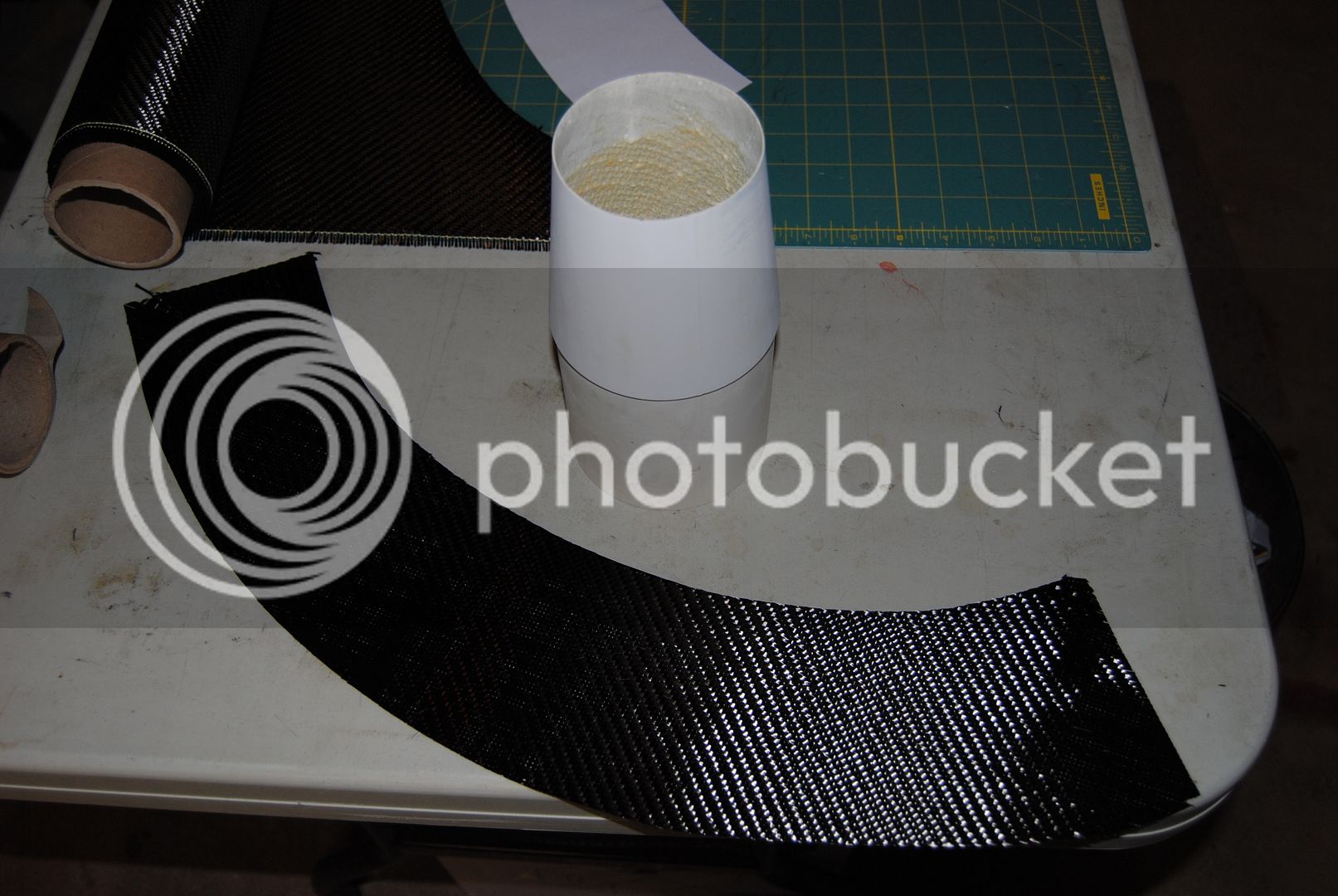

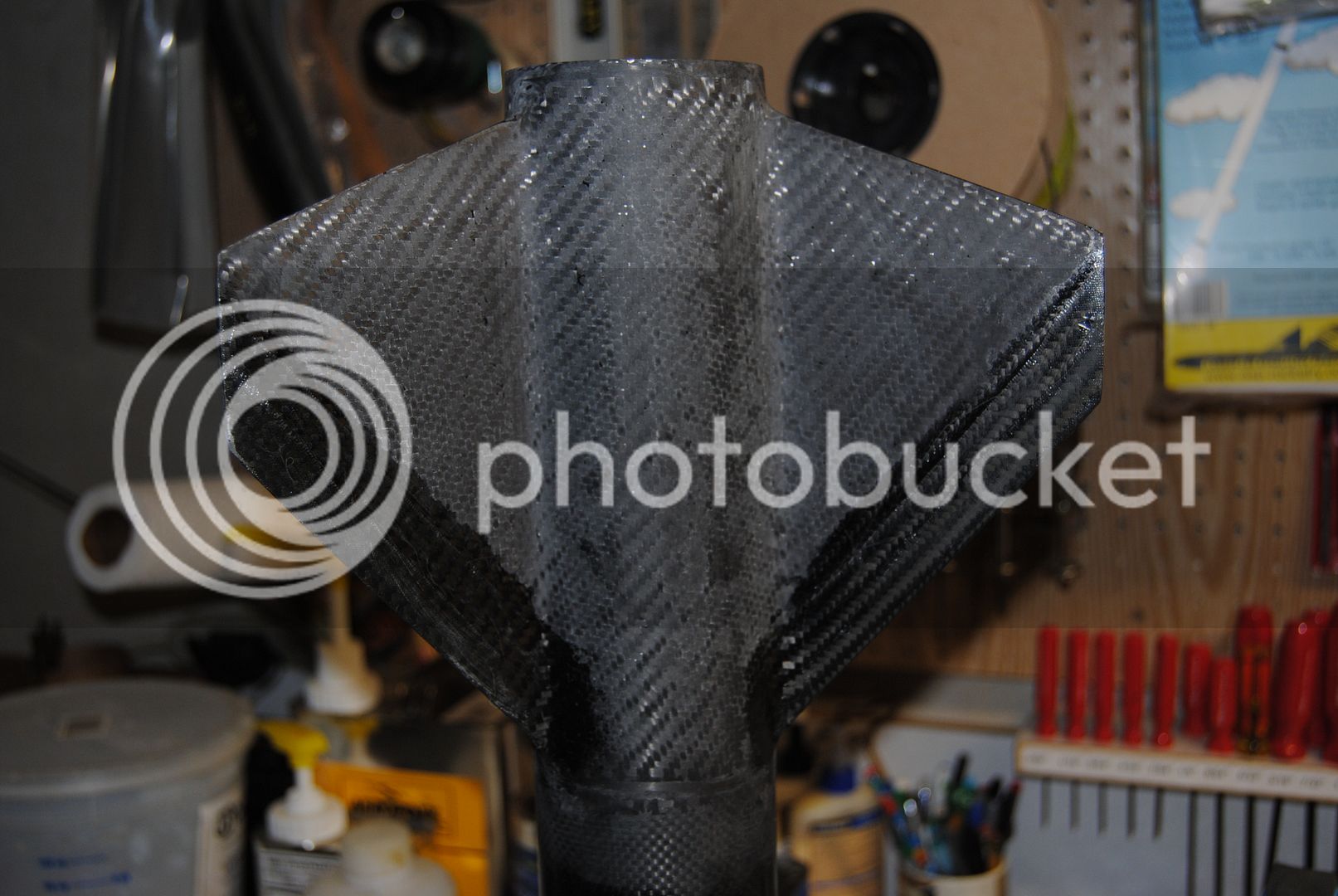

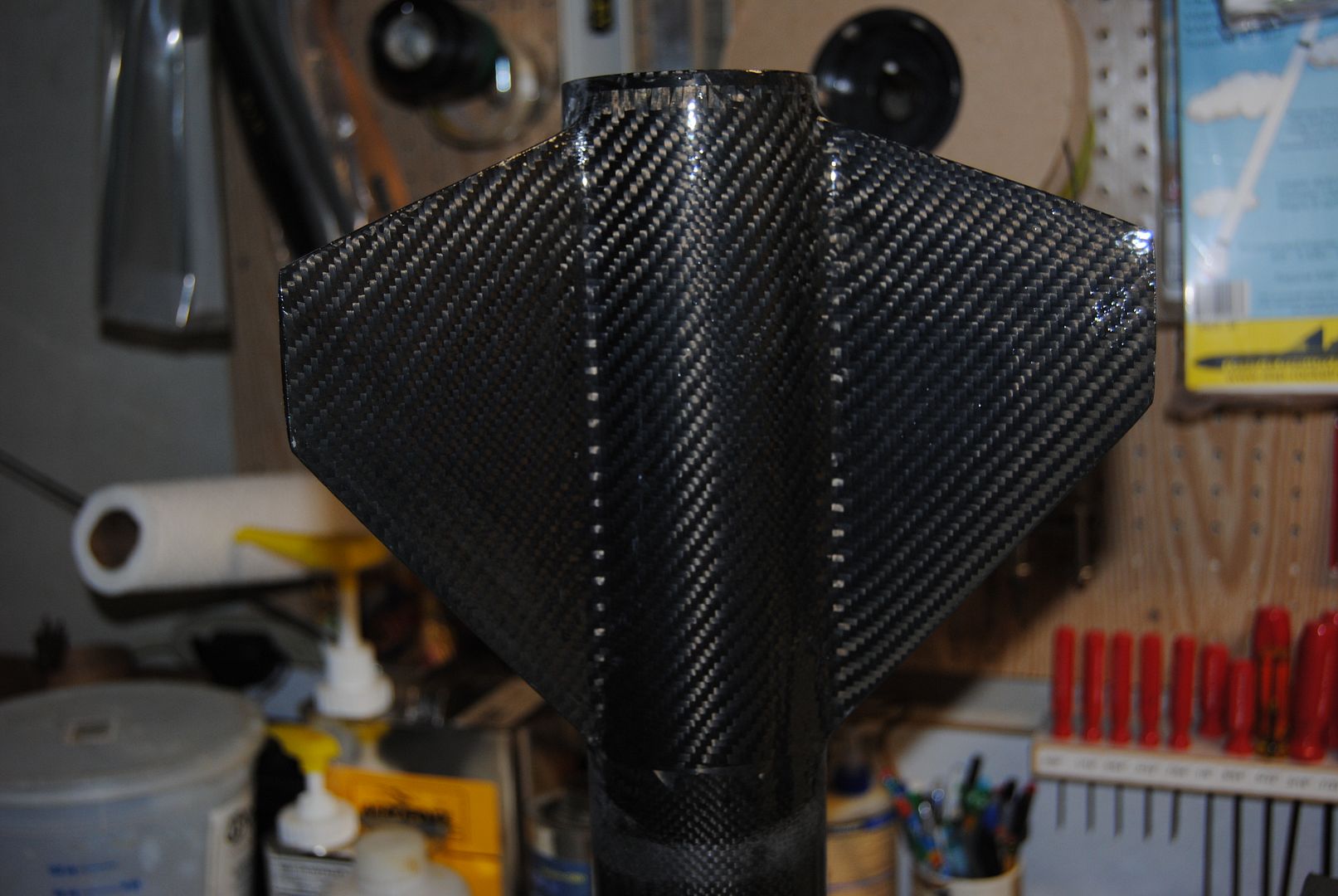

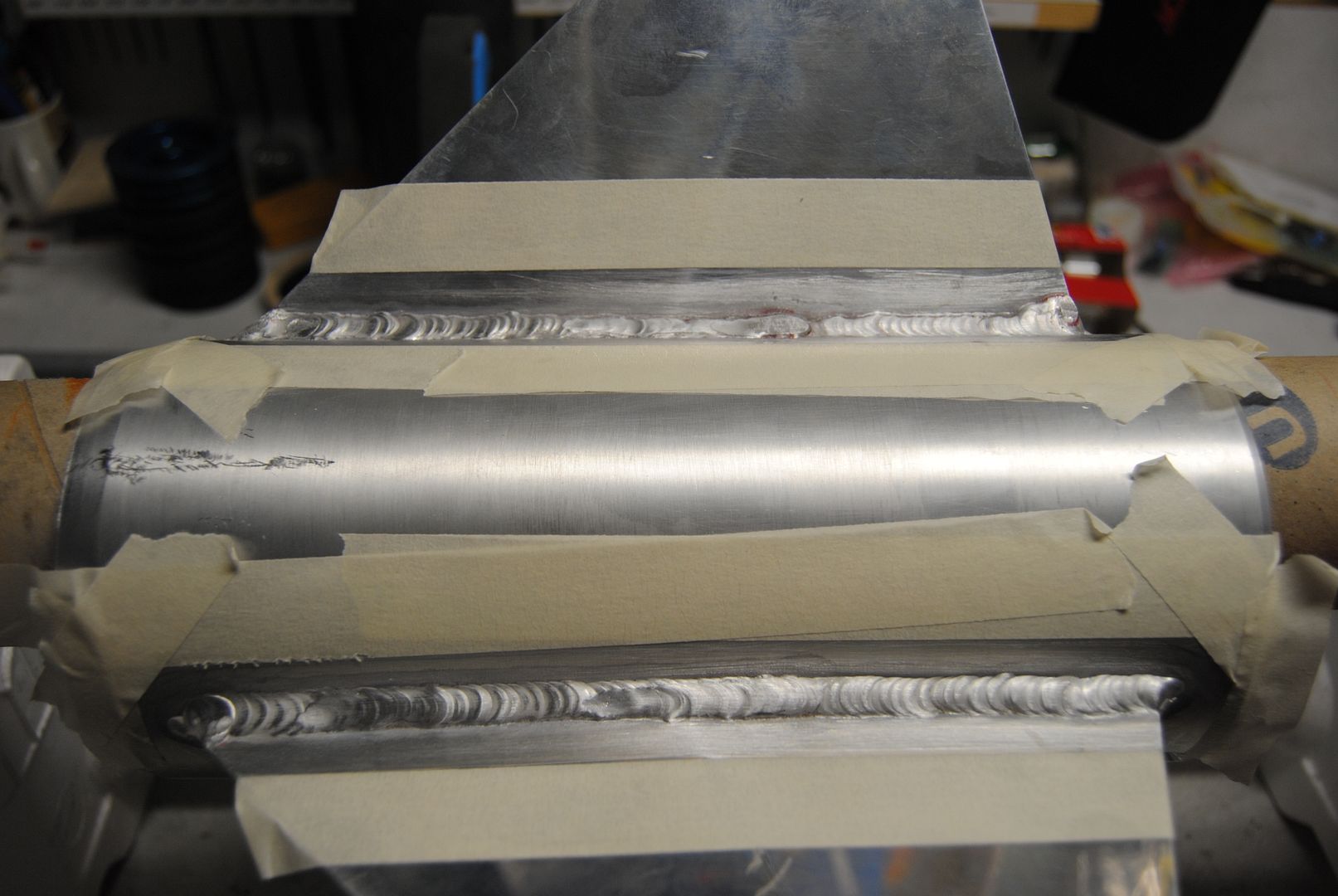

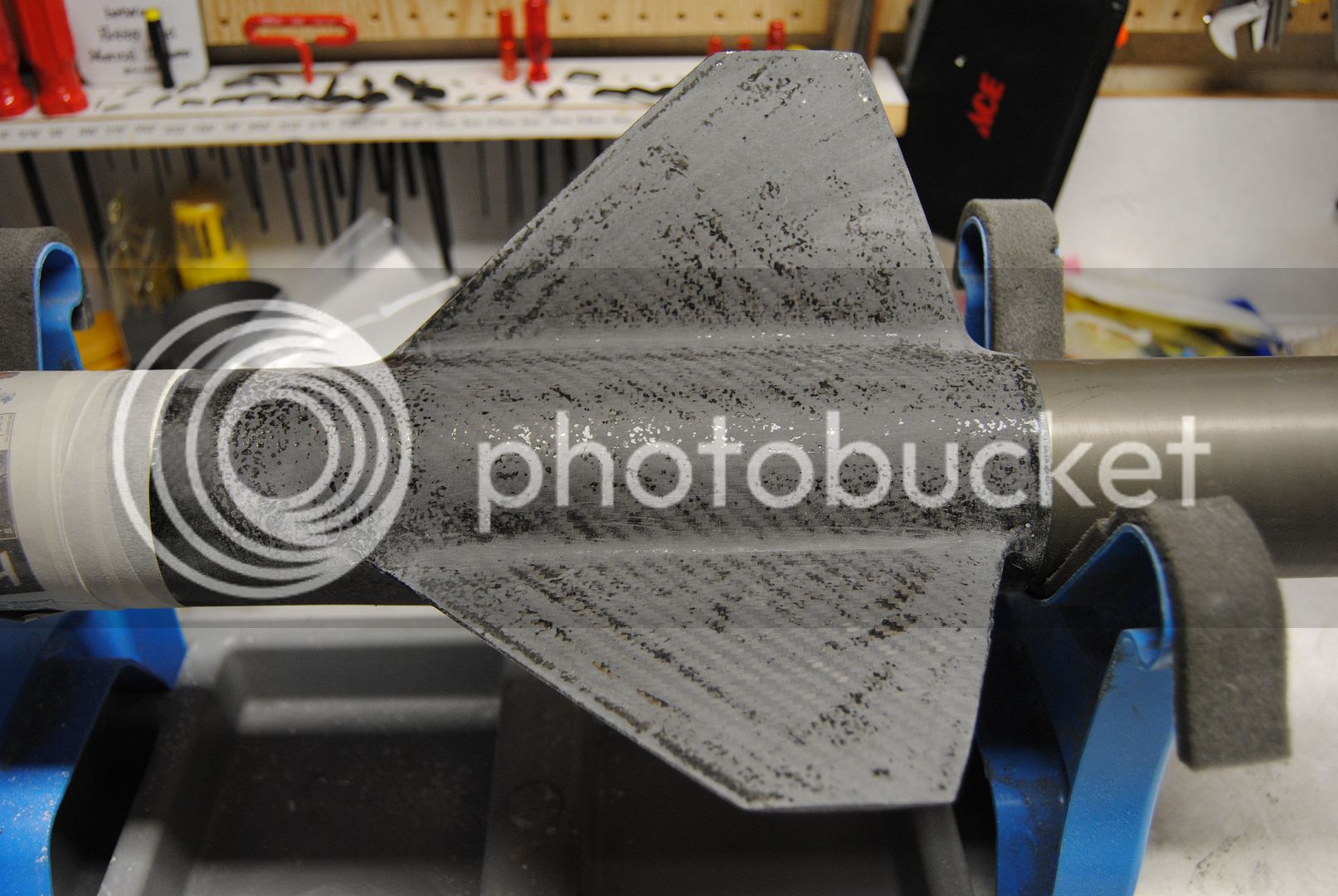

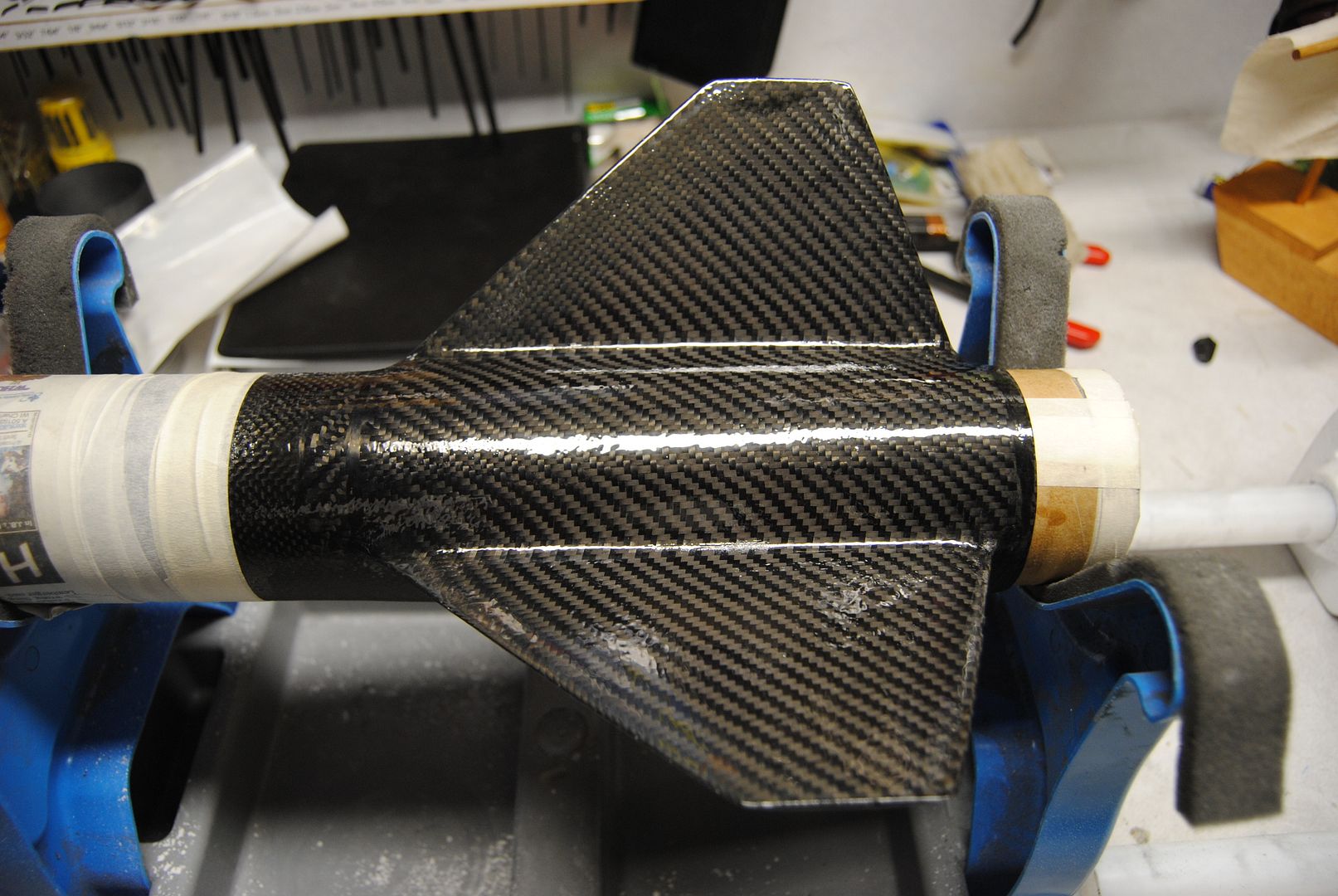

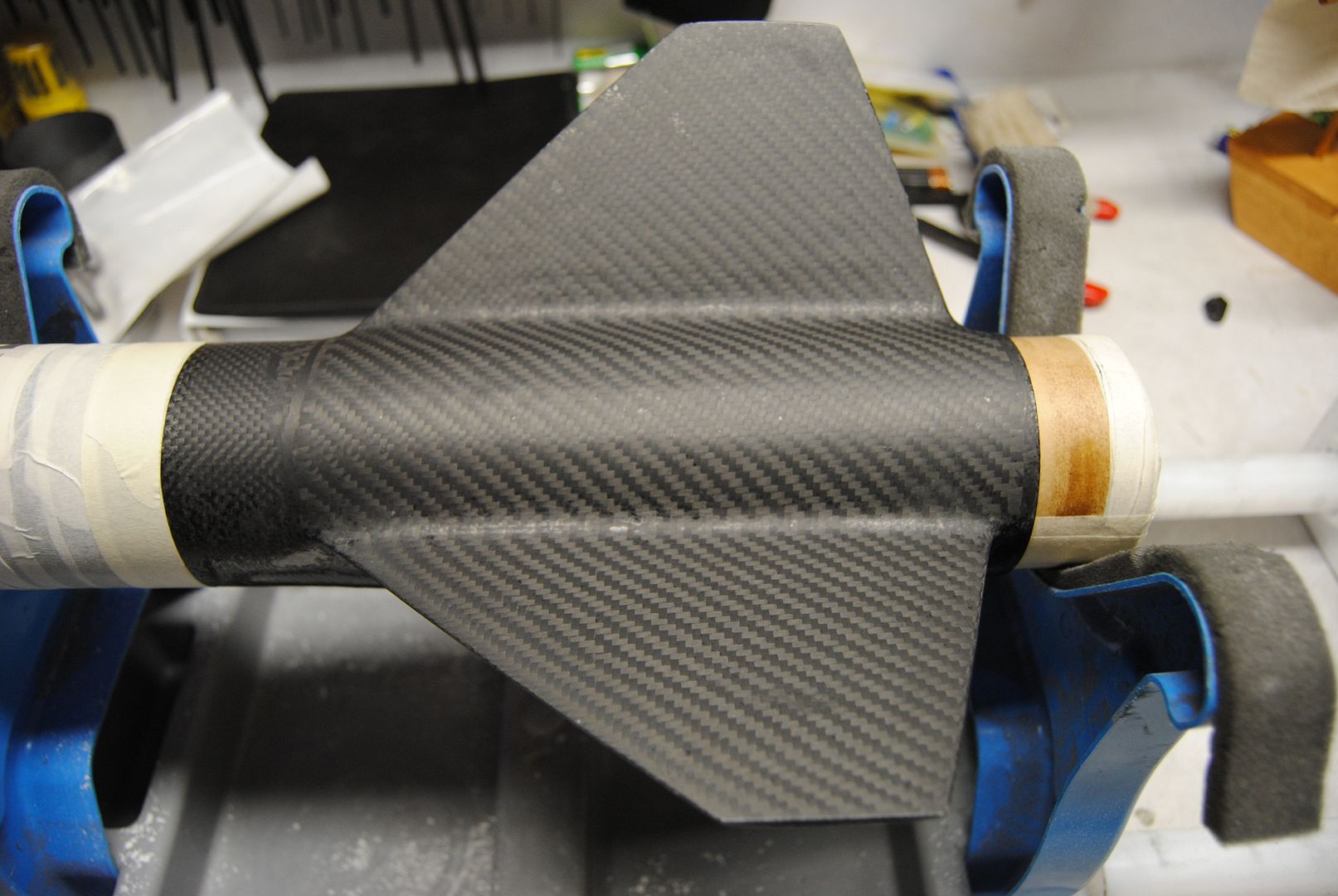

After the excess carbon was trimmed, the fins received a very light exterior sanding. The leading edges of both sustainer and booster were covered in multiple layers of 0.6oz plain weave E-glass laminated with 4461 epoxy: an important step in my opinion. Not overly pretty, but it looked like this:

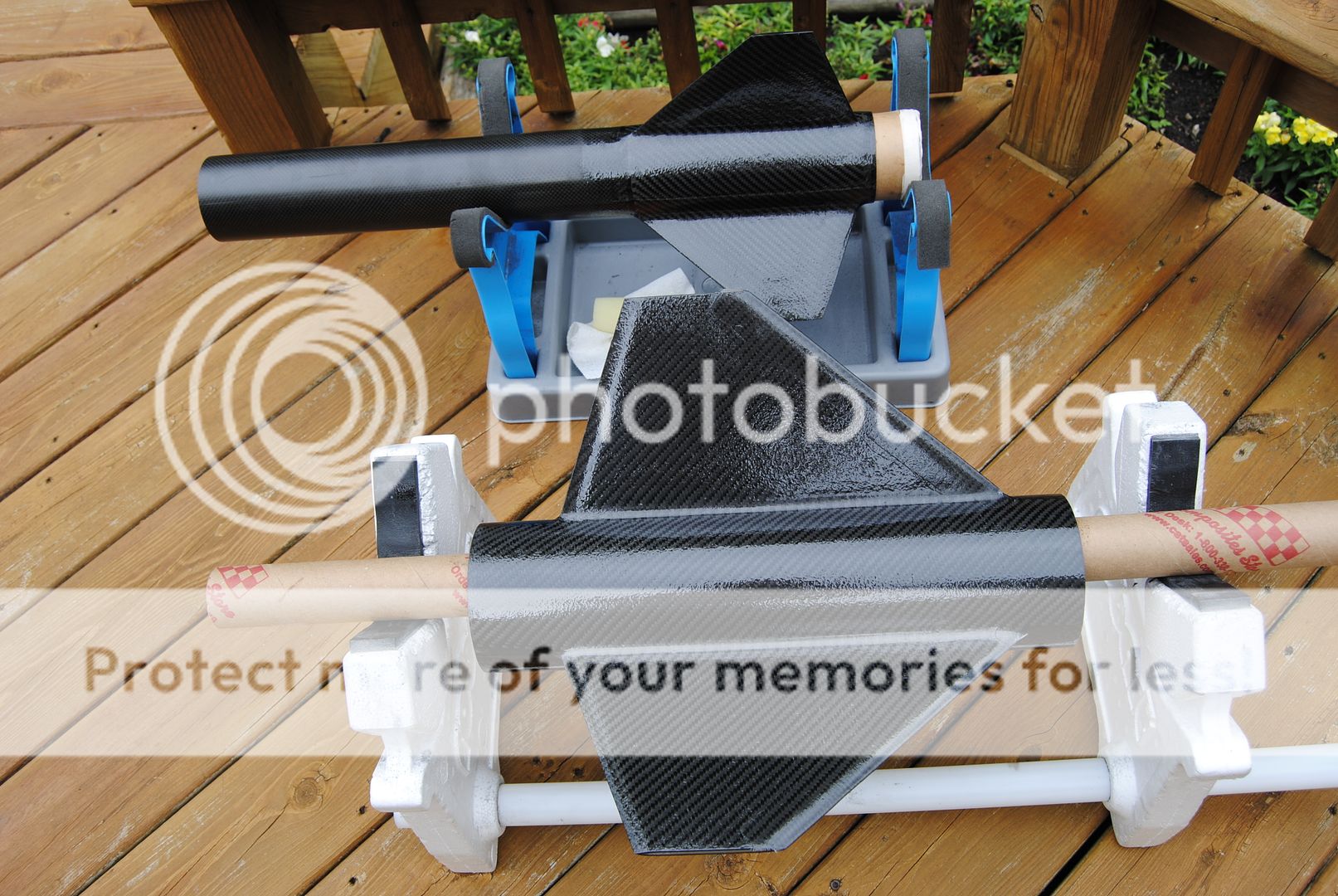

With the fin cans now functionally complete, it's time to work on the aesthetics and smooth things out a bit. The first coat of filler epoxy was lightly applied to both fin cans.

Brandon was proud and wanted to be in a photo with "his"

Hi-Flier XL:

Both components were placed outside to cure in the warm sun; wait, where did the sun go?

Tower Power

Yesterday afternoon came along and it was time to test assemble the tower. This dry run was a key step to insuring that assembly on the playa (hopefully) goes smoothly. The 16' tower was assembled in the horizontal plane much the same as we've done in the past with this tower's shorter brother. After adjusting the spacing for a 4.5" rocket, Brandon loaded the test rocket into the tower:

Tom (Dad) and I went to raise the assembly to vertical and discovered that we really needed a third person to keep the base in place. A quick call and Kevin was over to guard the foundation. With two of us lifting and one keeping the base in place, the rise to vertical was easy. Nevertheless, this is why we do a dry run in advance.

Now vertical, a trio of guy wires hold things in place. The neighbors ventured onto their back patio and asked only that we give a loud audible countdown before launching from the back yard. The Pad Manager looks things over:

For scale, a 6' ugly guy with green shorts was added to the photo field:

I'll be adding a second set of guy wires to the top set of hoops, a plywood base to the bottom, and a trio of adjustable standoffs to the base for the flight ops. Overall, assembly and the rise to vertical went very well. A huge

THANK YOU! to Tom and Kevin for helping assemble this pig on Labor Day!

Valuable lessons learned and noted from this assembly excersize; resulting in a

Launch Tower Checklist for implementation at Black Rock.

-Eric-

going to do with them(are you allowed to do internal parenthesis?)) ... plus, I can't afford to fly a 6" 2 stager, and don't have the patience to make a nosecone. a good one that is

.