bill2654

Well-Known Member

- Joined

- Sep 1, 2010

- Messages

- 2,542

- Reaction score

- 14

I see them referred to as wire size but what would something this small be used for? I also saw some very expensive sets.

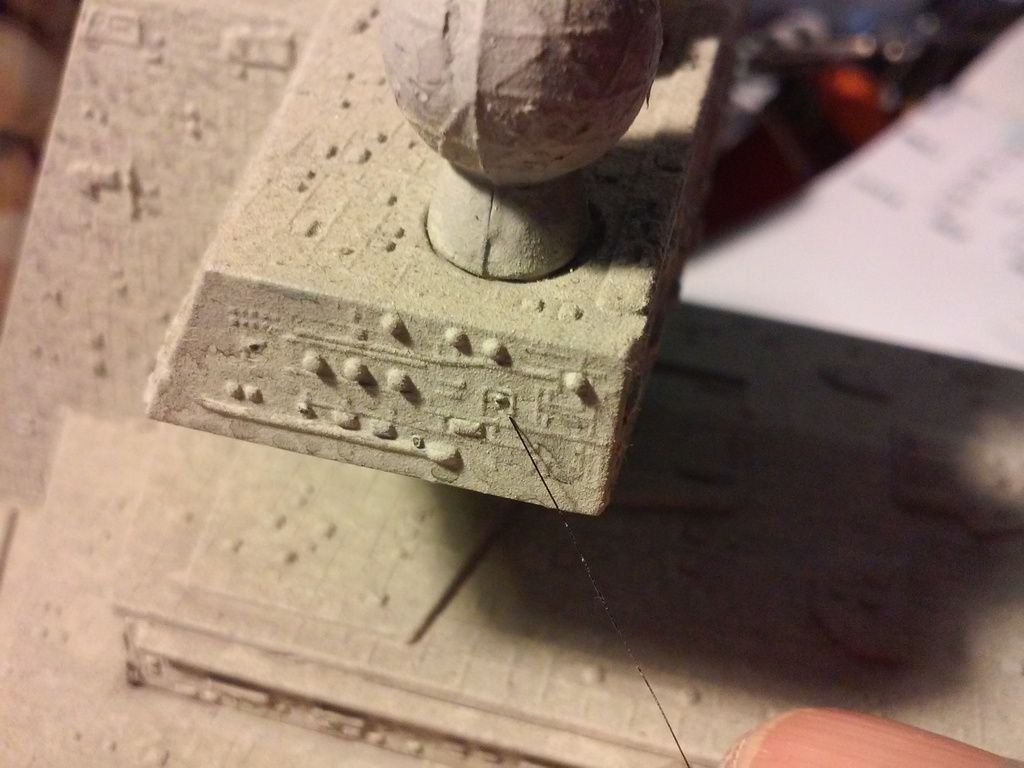

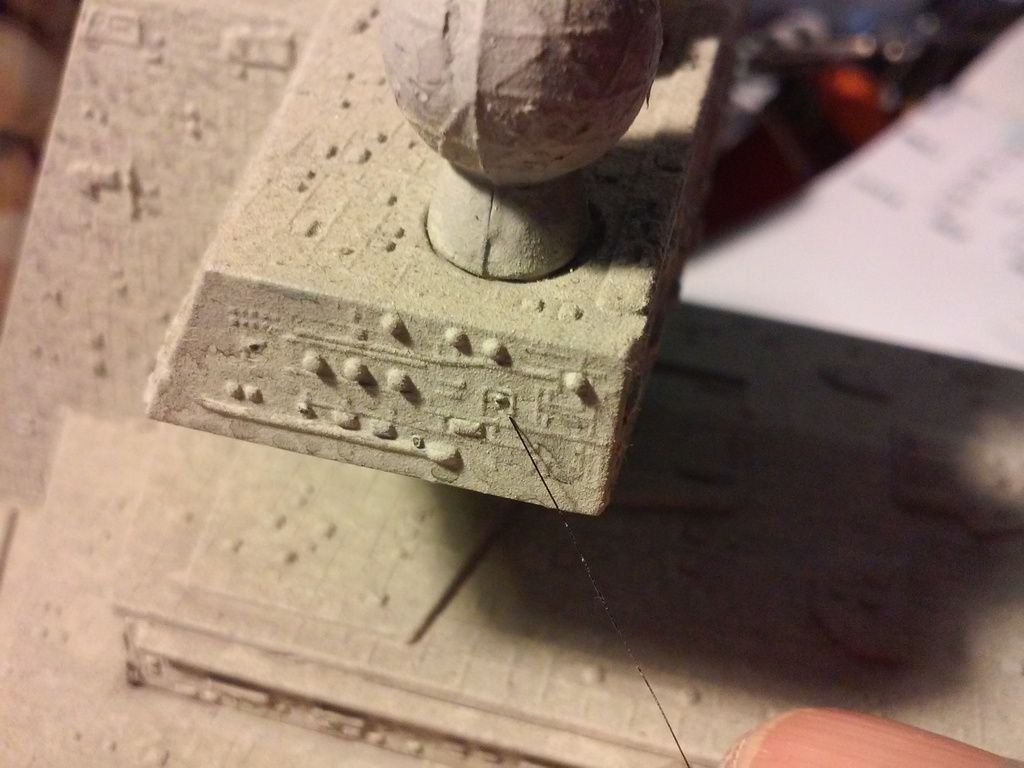

Circuit boards

Circuit boards

About 20 years ago I used similar tiny drill bits for an AMT/ERTL fiber optic Star Destroyer model kit.

The kit had a LOT of fiber optic cable basically about the size of human hairs and they provided a really cheap tiny drill bit and motorized drill for you to pretty much drill hundreds of holes. After a few dozen drilled holes, the cheap bit broke (of note was that it was set into plastic...offset is more like it) and I ordered 3 more at about $5 each directly from the company and after those quickly broke, I found a set of drills like the one you have above. Things got a lot easier after that.

I still have the kit and actually took it out to show some guests about a month ago...they were quite impressed, so it was almost worth the work.

Took some pics since I still had it out; however I don't have a good low-light camera and I also didn't want to burn any of the old sealed interior bulbs, so I used 6V instead of higher (12V really used to put on a show!).

Here's a pic of one of my hairs pointing at one of the drilled holes (which has a fiber optic strand glued into it). There are a bunch of other holes in the pic; however they're tricky to spot.

I also have the Enterprise and Deep Space Nine station fiber optic kits; however after this one was so much work, I never started the others (I'm saving that for retirement when I have more time).

Wow Ken, that Star Destroyer lighting is impressive!

I've used these small bits before when I was planking wood ship models.

Drill a small hole then drive in small nail to hold down the plank ends.

Enter your email address to join: