dixontj93060

Well-Known Member

- Joined

- Feb 19, 2009

- Messages

- 13,083

- Reaction score

- 45

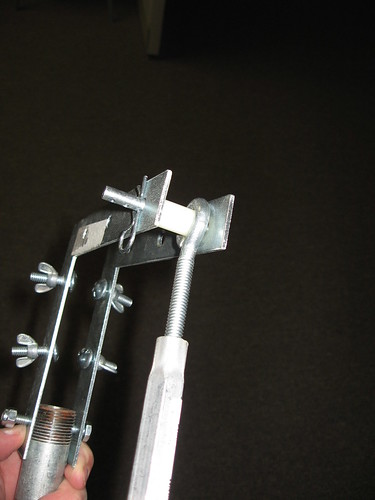

This pad has been in use for nearly three years now, but I never posted its design. I was motivated to do so when I saw a few members contemplating dropping nearly $50 on an adjustable rail bracket. Thus I wanted share this design as an option. I believe it provides a full range of tilt and swivel adjustments that I have seen on much more expensive alternatives. I have used it to launch 4" rockets on J motors. I believe the design, when assembled fully is capable of supporting K motors. Price for the whole pad was a bit over $20 and now, likely adjusted for inflation, still around $30.