Cory

Well-Known Member

Recently received approval from two TAPs and started working on my L3 project. I have made some good early progress over the last couple of weekends and figured it was time to get a build thread going to document the journey. HERE is a link to the Flikr album that will be updated as I go along and will contain the same pictures as here plus many more. This is an Ultimate Wildman kit and the cert attempt will be with an Aerotech M2500 (98/10240). The current goal is to fly on or before Kloudburst in April at the rocket pasture.

[url=https://flic.kr/p/2aXndfU]

[url=https://flic.kr/p/2aXndum]

All recovery harnesses and components were purchased from Ted over at ONEBADHAWK and was a pleasure as always to deal with. I will give more detail later, but safe to say these custom harnesses are the best gear I have yet put into a rocket.

[url=https://flic.kr/p/2aXncZy]

[url=https://flic.kr/p/2cC1ESA]

Started the fun off with the obligatory parts bath.

[url=https://flic.kr/p/2aXneTU]

Decided the MMT was as good a place as any to start and so mixed up the first batch of ROCKETPOXY for this build. This was my first time using the flange type Aeropack, but especially with a motor case on hand, the installation was not difficult. After the AP was in place and the Y-Harness attached to the forward CR via two U-bolts- the MMT was ROCKETPOXIED in place.

[url=https://flic.kr/p/2cC1Efy]

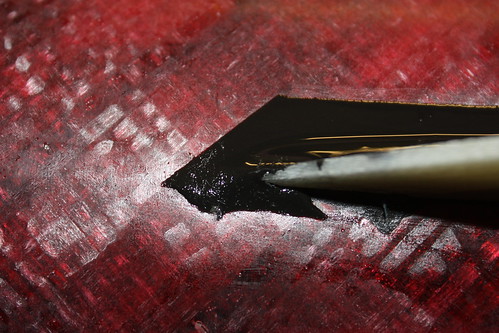

After prepping the fin root with 100 grit, I notched it with a hacksaw. Not really sure if this is necessary or better, but trying to follow the advice I have seen given multiple times hear and heard in person – DO WHAT HAS WORKED IN THE PAST ON CERT ATTEMPTS, NOT THE TIME TO TRY SOMETHING NEW!- I have had great success with fin roots prepped this way.

[url=https://flic.kr/p/2dDDb8m]

[url=https://flic.kr/p/2dDDae7]

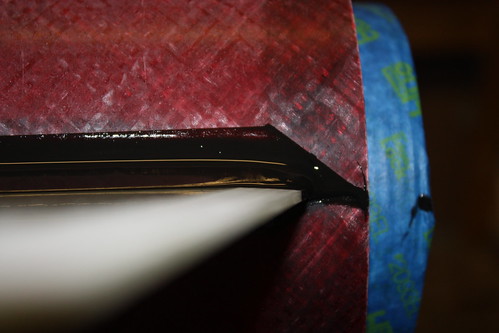

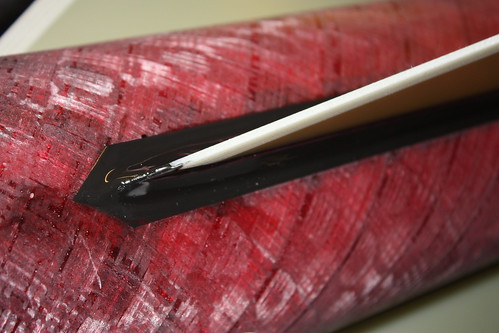

Using the good ole’ double butter method-coupled with trusty Estes fin alignment jig and the first fin is attached! I had previously used the Dremel to notch the fin root to allow injection of the internal fillets.

[url=https://flic.kr/p/2ckt8SZ]

[url=https://flic.kr/p/2dDDbFW]

[url=https://flic.kr/p/2aXyUFm]

[url=https://flic.kr/p/2aXyVnG]

I have no idea why all the text after the first picture is linked to Flikr - Sorry.[/url][/url][/url][/url][/url][/url][/url][/url][/url][/url][/url][/url]

[url=https://flic.kr/p/2aXndfU]

[url=https://flic.kr/p/2aXndum]

All recovery harnesses and components were purchased from Ted over at ONEBADHAWK and was a pleasure as always to deal with. I will give more detail later, but safe to say these custom harnesses are the best gear I have yet put into a rocket.

[url=https://flic.kr/p/2aXncZy]

[url=https://flic.kr/p/2cC1ESA]

Started the fun off with the obligatory parts bath.

[url=https://flic.kr/p/2aXneTU]

Decided the MMT was as good a place as any to start and so mixed up the first batch of ROCKETPOXY for this build. This was my first time using the flange type Aeropack, but especially with a motor case on hand, the installation was not difficult. After the AP was in place and the Y-Harness attached to the forward CR via two U-bolts- the MMT was ROCKETPOXIED in place.

[url=https://flic.kr/p/2cC1Efy]

After prepping the fin root with 100 grit, I notched it with a hacksaw. Not really sure if this is necessary or better, but trying to follow the advice I have seen given multiple times hear and heard in person – DO WHAT HAS WORKED IN THE PAST ON CERT ATTEMPTS, NOT THE TIME TO TRY SOMETHING NEW!- I have had great success with fin roots prepped this way.

[url=https://flic.kr/p/2dDDb8m]

[url=https://flic.kr/p/2dDDae7]

Using the good ole’ double butter method-coupled with trusty Estes fin alignment jig and the first fin is attached! I had previously used the Dremel to notch the fin root to allow injection of the internal fillets.

[url=https://flic.kr/p/2ckt8SZ]

[url=https://flic.kr/p/2dDDbFW]

[url=https://flic.kr/p/2aXyUFm]

[url=https://flic.kr/p/2aXyVnG]

I have no idea why all the text after the first picture is linked to Flikr - Sorry.[/url][/url][/url][/url][/url][/url][/url][/url][/url][/url][/url][/url]

[url=https://flic.kr/p/Q8DMMZ]

[url=https://flic.kr/p/Q8DMMZ]

[url=https://flic.kr/p/Q8DMYv]

[url=https://flic.kr/p/Q8DMYv]

[url=https://flic.kr/p/2cv9KQZ]

[url=https://flic.kr/p/2cv9KQZ]

[url=https://flic.kr/p/2dPgZjj]

[url=https://flic.kr/p/2dPgZjj]