The laundry/epoxy/sanding room has been busy this month. We decided to attend Airfest and both Sharon and I have several projects that need to be done before the big road trip.

It started with the Wild child when the expanding foam escaped containment in the fincan. Sorry, no pics. we were much to busy cleaning up.

This week we have stuck fins in the Wild Thang and my new X-Celerator, with the Super Duper Dark Jart soon to follow. I was running external fillets today and looked around my work area, quite a collection! I posed a pic. so I can remember what all is there:

Left to right:

1 qt. Rocketpoxy

1 pt. Proline 4500

squeeze bottles of Rocketpoxy

1 qt. West systems 105/205 (behind the goof off)

syringe of Hammerhead 5 min.

Great Planes 30 min.

JB weld (behind the Great Planes)

Microballons filler

Milled fiberglass filler

Chopped carbon

All of which has seen use this month.

Sharon used West Systems with some chopped carbon fiber to inject fillets in her Wild Thang and then again with the microballons for small fillets:

The edge of the W is so close to the BT that a larger fillet would flow through. So she just poured some WS with microballons in and let it settle. No wet finger or other tool to smooth, just leveled it and let it set:

We do have a handy curing oven right next to the epoxy room, called a garage:

Today the thermostat is set for 107* while just outside the sunshine is cooking along at 110*:

I'm slowly getting the hang of this new Rocketpoxy, mainly by ignoring all the advise given on TRF and developing my own technique. First, don't try to do more than one set of external fillets at a time, regardless of how thick you think it is, it will still flow if you turn your rocket, even after an hour from mixing with the room temp. at 76*.

Don't bother letting it set up for 30 min. either, it just makes it harder to work with, and it will still flow, unless you have a handy garage like mine. Nothing flows after a few minutes in there, even West systems. If you're not used to it, it can even stop the blood flowing in your circulatory system. :y:

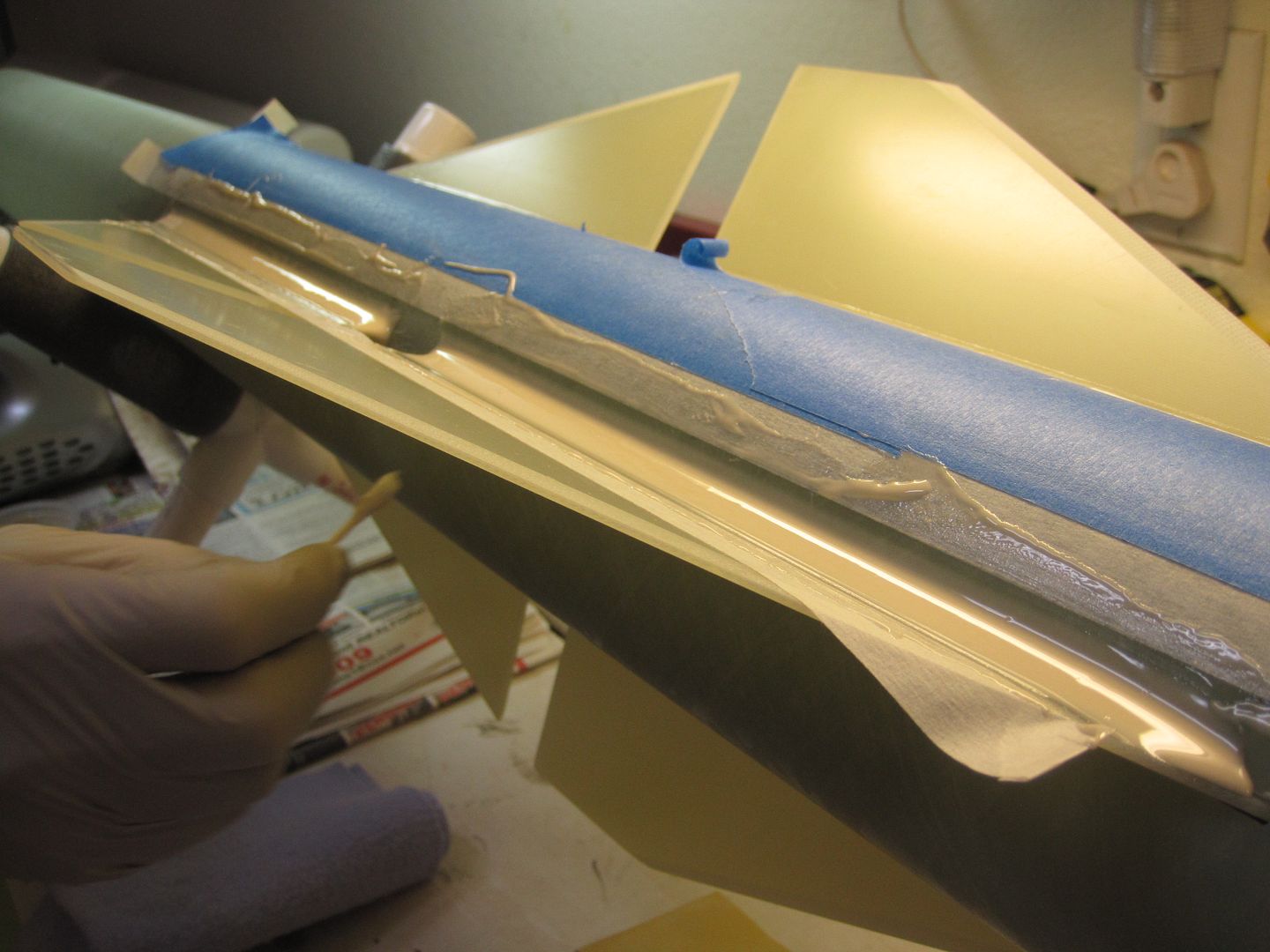

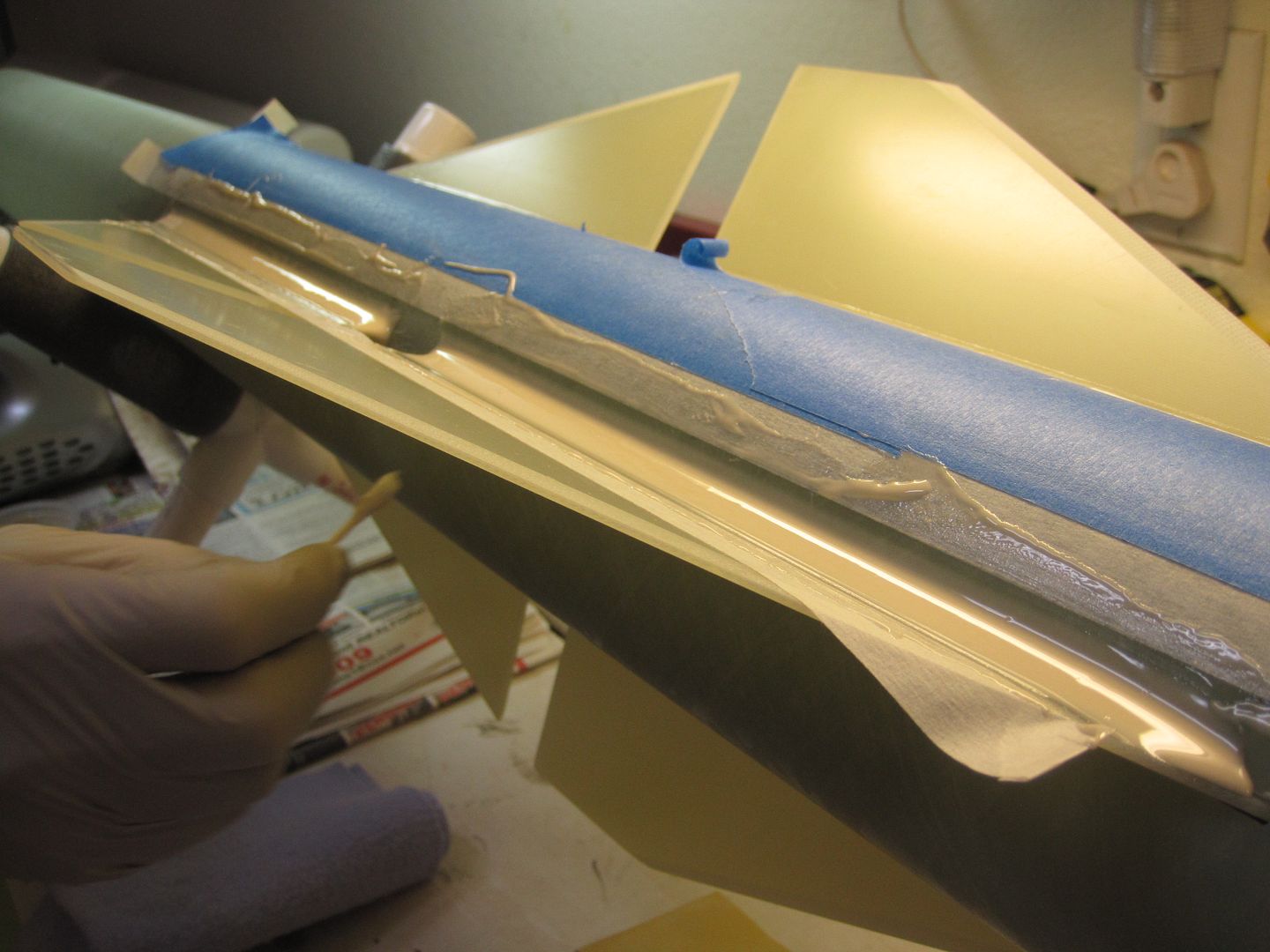

Here is the second set of fillets I did today, using 60 grams for all four fins:

I'm getting pretty good results now, but in my opinion it can't beat the Proline for a smooth fillet.

We were sticking on Aeropac retainers and I decided to finish up a tube of JB Weld. After two retainers were finished, there was some left, so Sharon used it to attach 1/2" kevlar to the MMT of her new Jart:

The X-Celerator is held together mostly with Rocketpoxy, with JB weld on the retainer and some Hammerhead on the upper CR to hold it in place for fitting fins. I talked to CJ this week and he convinced me to not inject my inner fillets. I double buttered the roots and stuck them in twice, set it out in the oven for an hour and did the next set. Sharon is going to try this method on the new Jart later today, then follow up with some Rocketpoxy fillets tinted black so it can go mostly naked with a little future floor wax to seal the nifty new Stickershock stickers she got from Mark. I'm painting the X-Celerator and her Wild Child, and her Wild Thang this weekend. Have to start early or the paint will dry before it can get from the rattlecan to the rocket. But it does speed up the curing process, and as you all know, "It's a dry heat".

It started with the Wild child when the expanding foam escaped containment in the fincan. Sorry, no pics. we were much to busy cleaning up.

This week we have stuck fins in the Wild Thang and my new X-Celerator, with the Super Duper Dark Jart soon to follow. I was running external fillets today and looked around my work area, quite a collection! I posed a pic. so I can remember what all is there:

Left to right:

1 qt. Rocketpoxy

1 pt. Proline 4500

squeeze bottles of Rocketpoxy

1 qt. West systems 105/205 (behind the goof off)

syringe of Hammerhead 5 min.

Great Planes 30 min.

JB weld (behind the Great Planes)

Microballons filler

Milled fiberglass filler

Chopped carbon

All of which has seen use this month.

Sharon used West Systems with some chopped carbon fiber to inject fillets in her Wild Thang and then again with the microballons for small fillets:

The edge of the W is so close to the BT that a larger fillet would flow through. So she just poured some WS with microballons in and let it settle. No wet finger or other tool to smooth, just leveled it and let it set:

We do have a handy curing oven right next to the epoxy room, called a garage:

Today the thermostat is set for 107* while just outside the sunshine is cooking along at 110*:

I'm slowly getting the hang of this new Rocketpoxy, mainly by ignoring all the advise given on TRF and developing my own technique. First, don't try to do more than one set of external fillets at a time, regardless of how thick you think it is, it will still flow if you turn your rocket, even after an hour from mixing with the room temp. at 76*.

Don't bother letting it set up for 30 min. either, it just makes it harder to work with, and it will still flow, unless you have a handy garage like mine. Nothing flows after a few minutes in there, even West systems. If you're not used to it, it can even stop the blood flowing in your circulatory system. :y:

Here is the second set of fillets I did today, using 60 grams for all four fins:

I'm getting pretty good results now, but in my opinion it can't beat the Proline for a smooth fillet.

We were sticking on Aeropac retainers and I decided to finish up a tube of JB Weld. After two retainers were finished, there was some left, so Sharon used it to attach 1/2" kevlar to the MMT of her new Jart:

The X-Celerator is held together mostly with Rocketpoxy, with JB weld on the retainer and some Hammerhead on the upper CR to hold it in place for fitting fins. I talked to CJ this week and he convinced me to not inject my inner fillets. I double buttered the roots and stuck them in twice, set it out in the oven for an hour and did the next set. Sharon is going to try this method on the new Jart later today, then follow up with some Rocketpoxy fillets tinted black so it can go mostly naked with a little future floor wax to seal the nifty new Stickershock stickers she got from Mark. I'm painting the X-Celerator and her Wild Child, and her Wild Thang this weekend. Have to start early or the paint will dry before it can get from the rattlecan to the rocket. But it does speed up the curing process, and as you all know, "It's a dry heat".