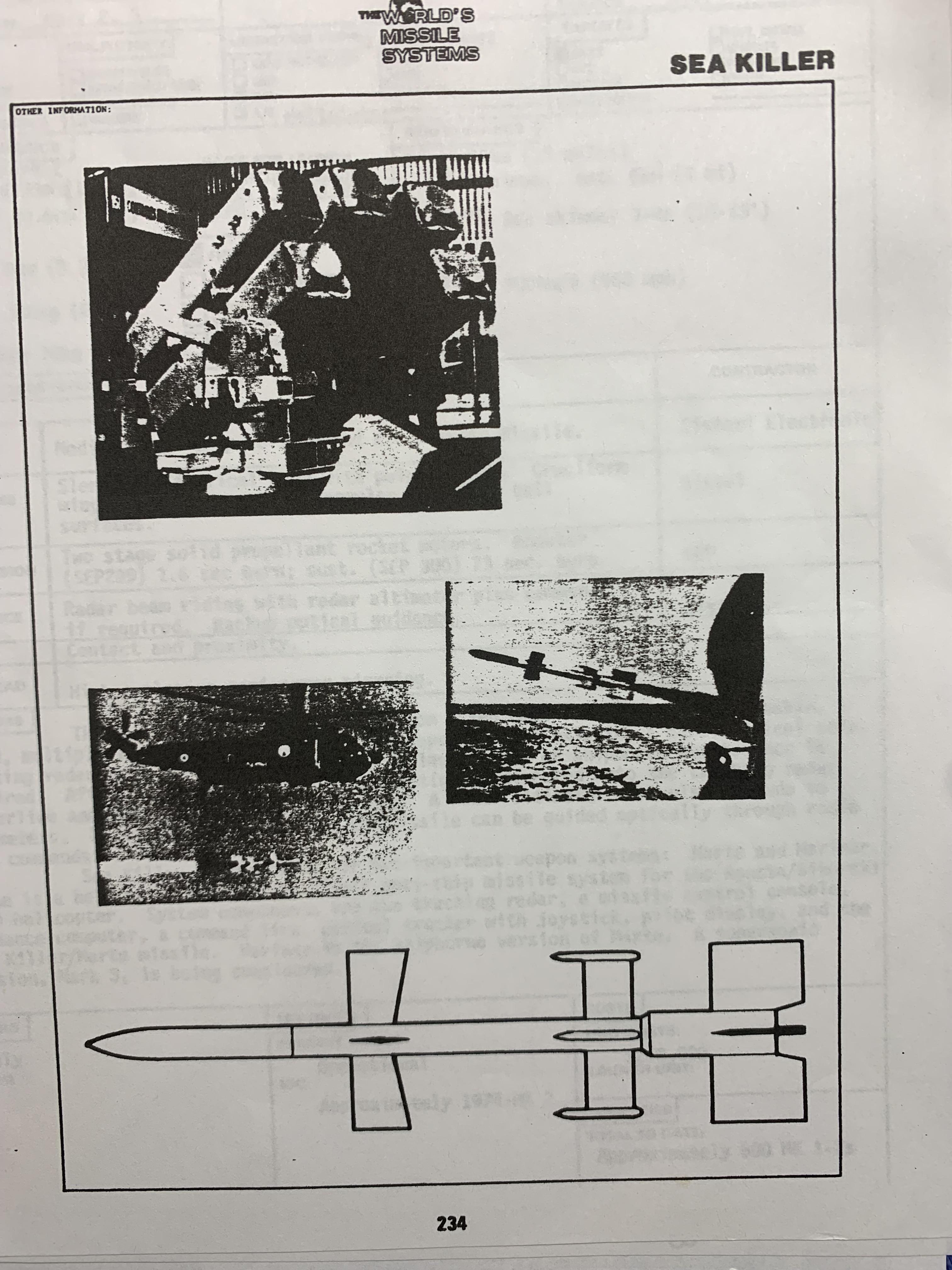

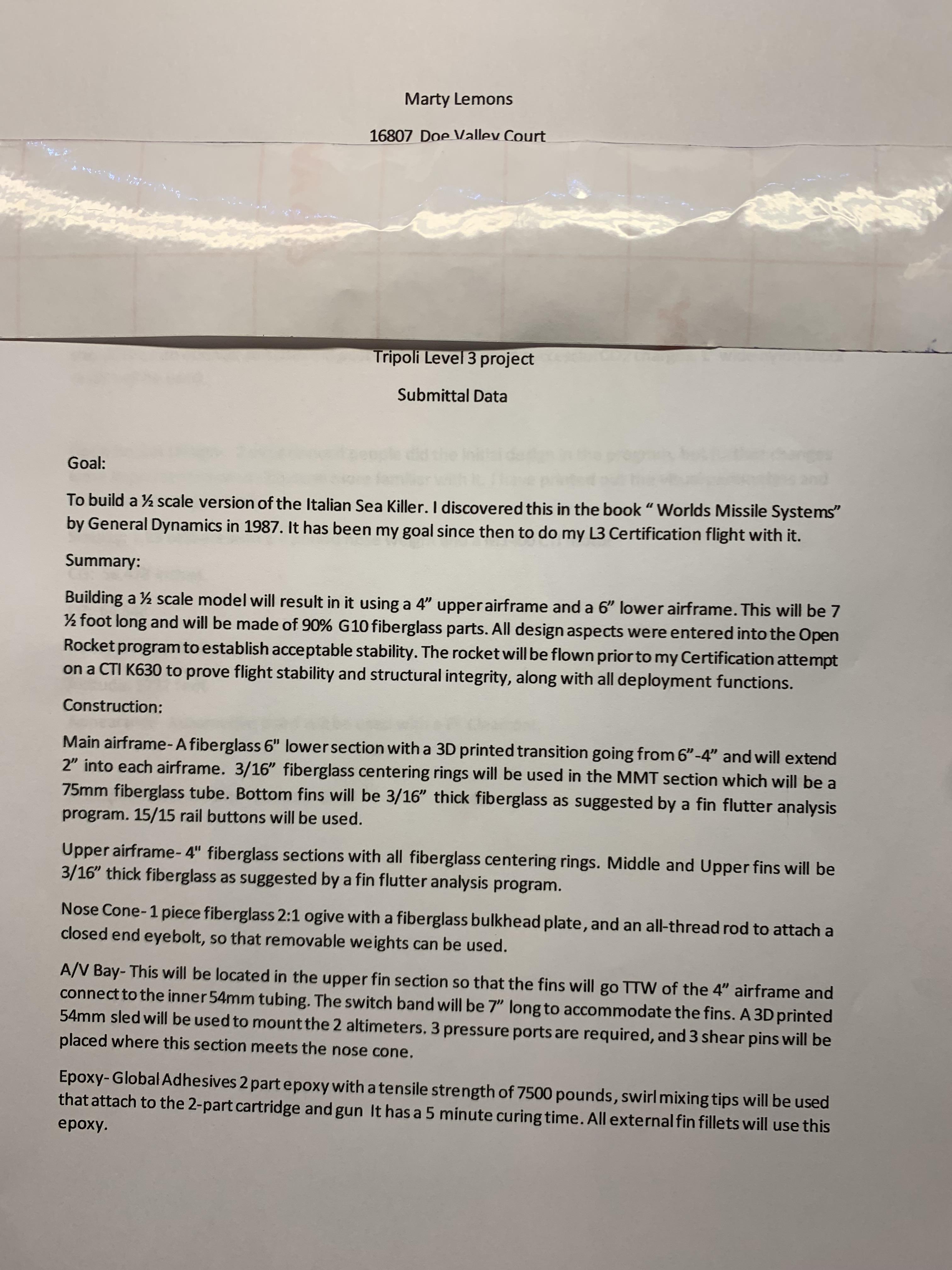

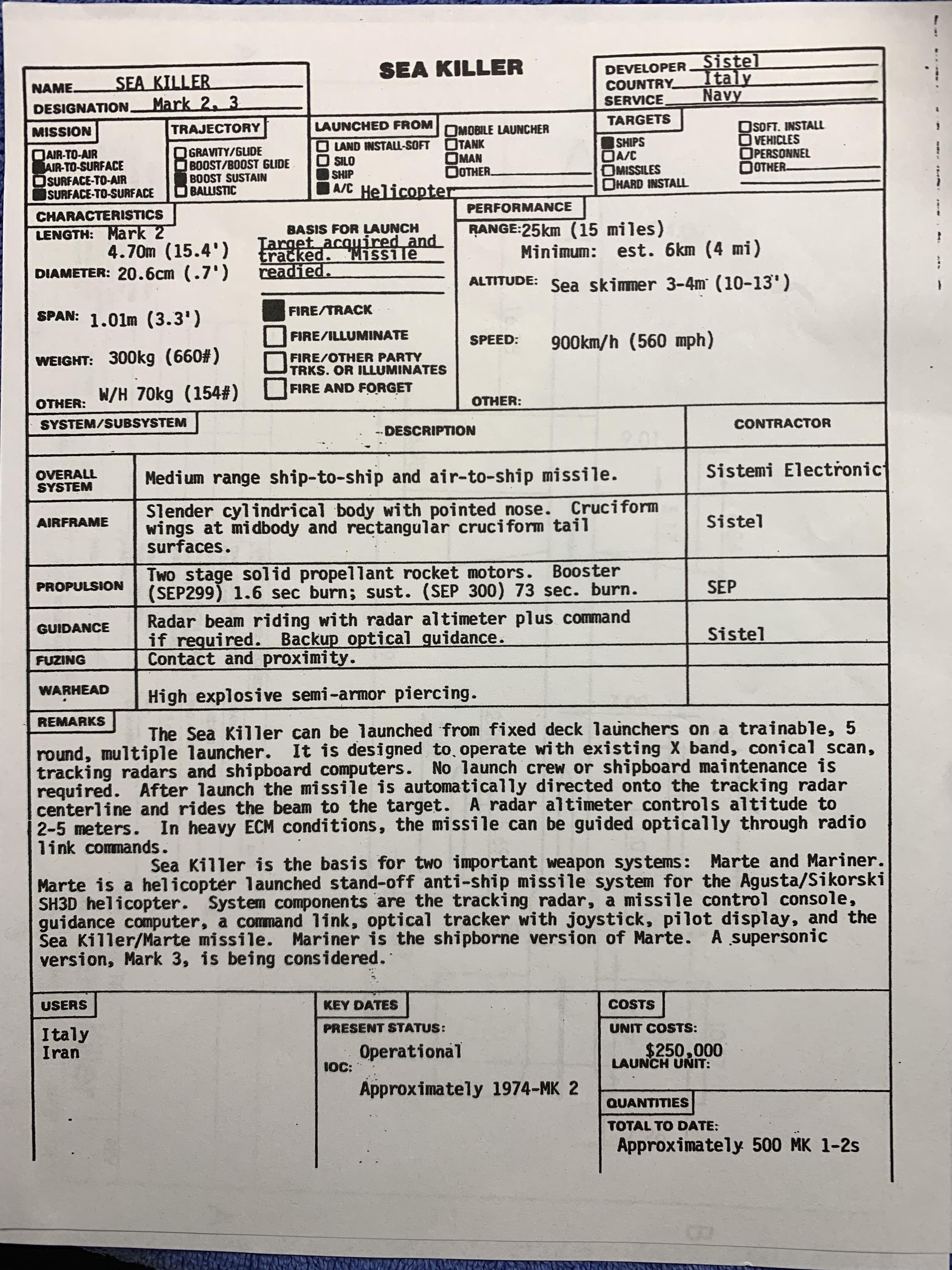

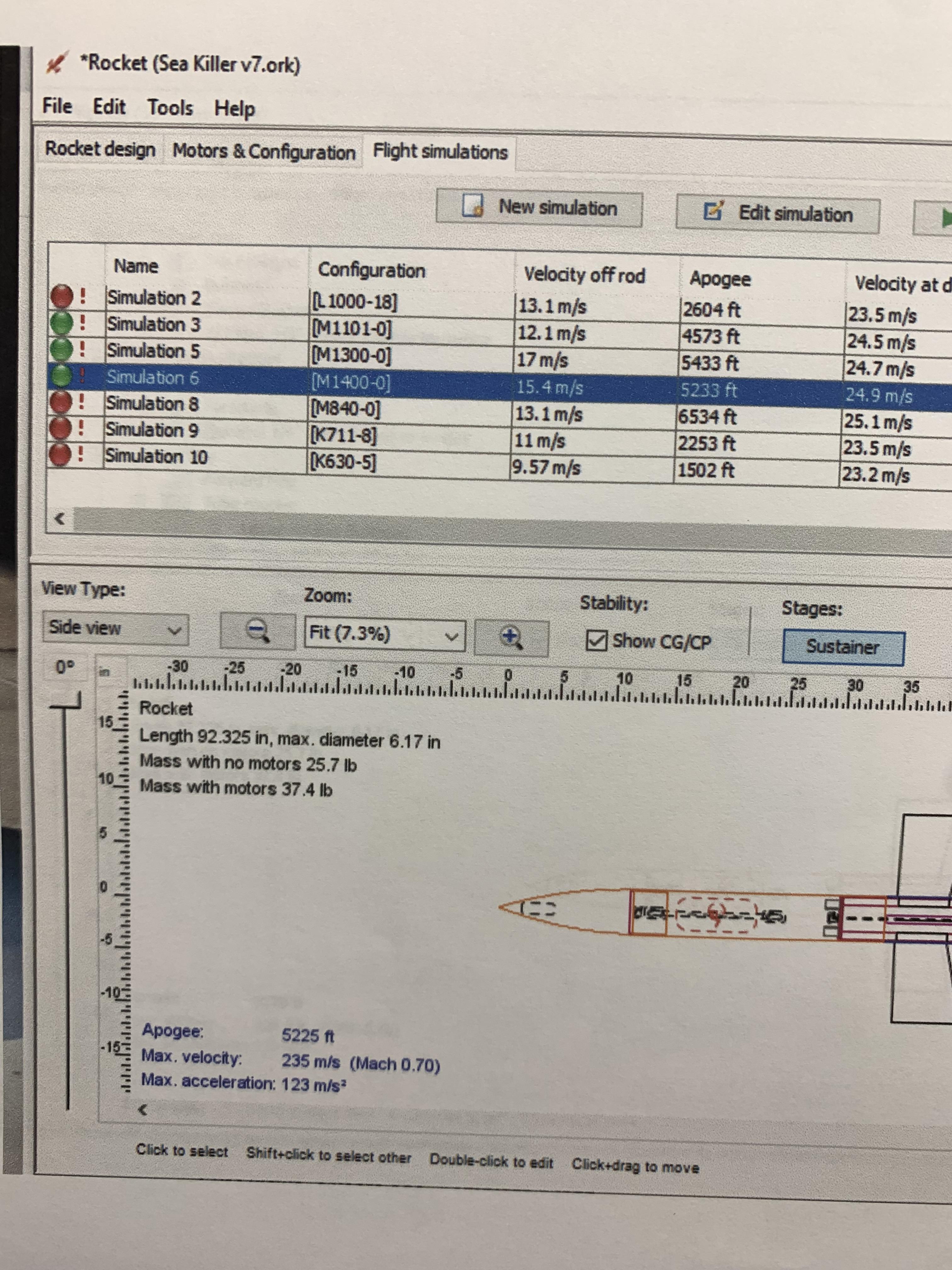

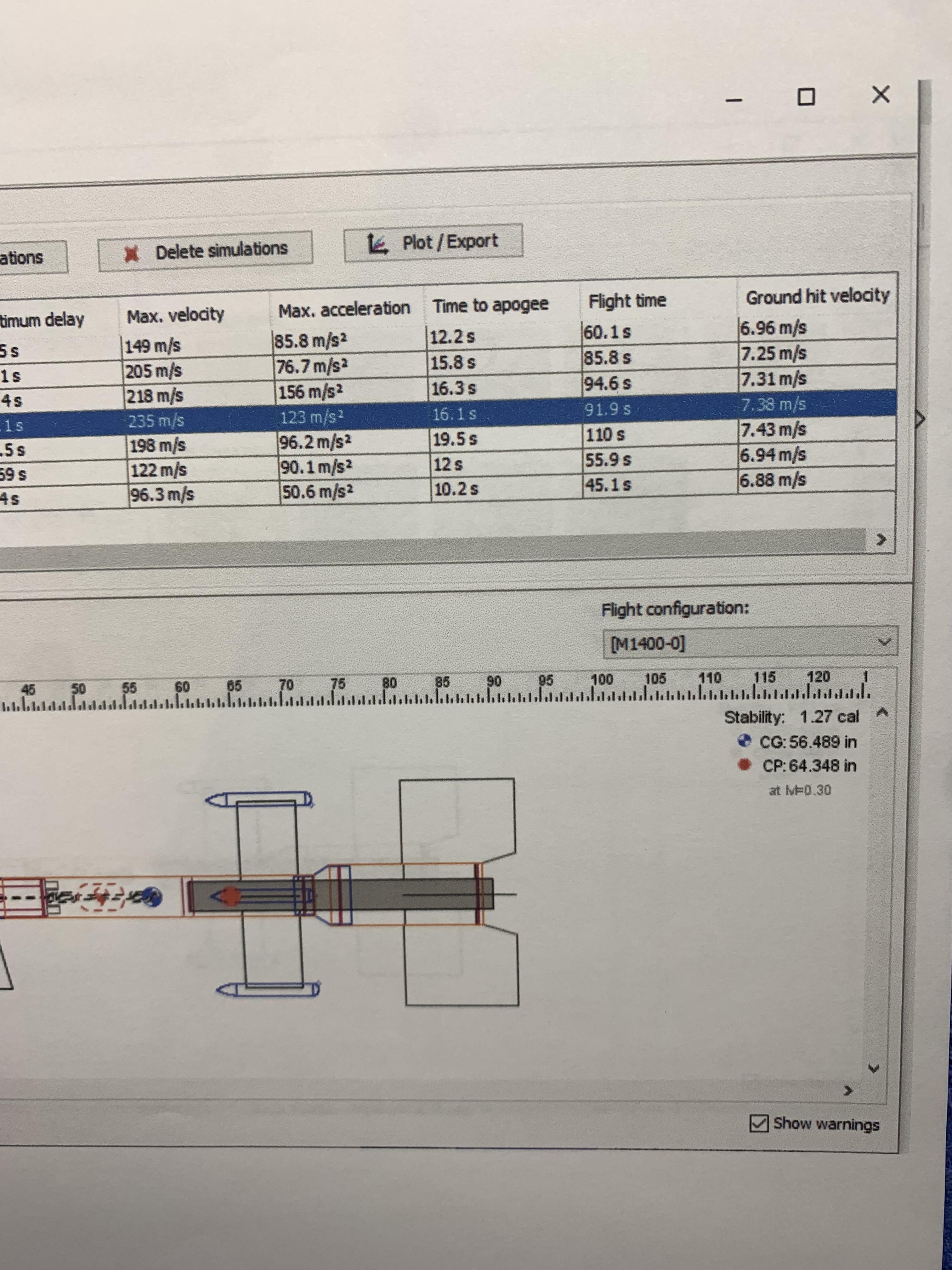

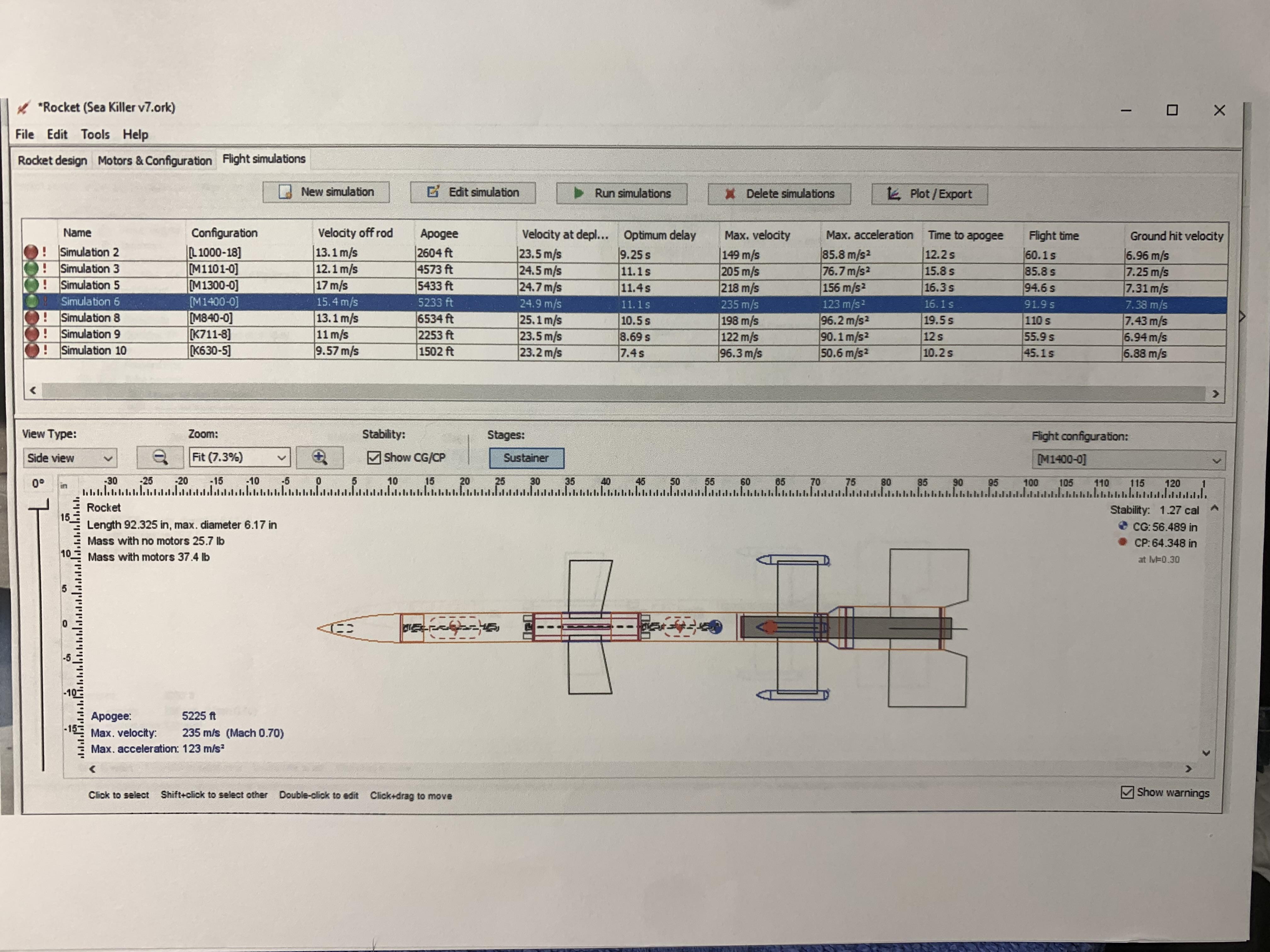

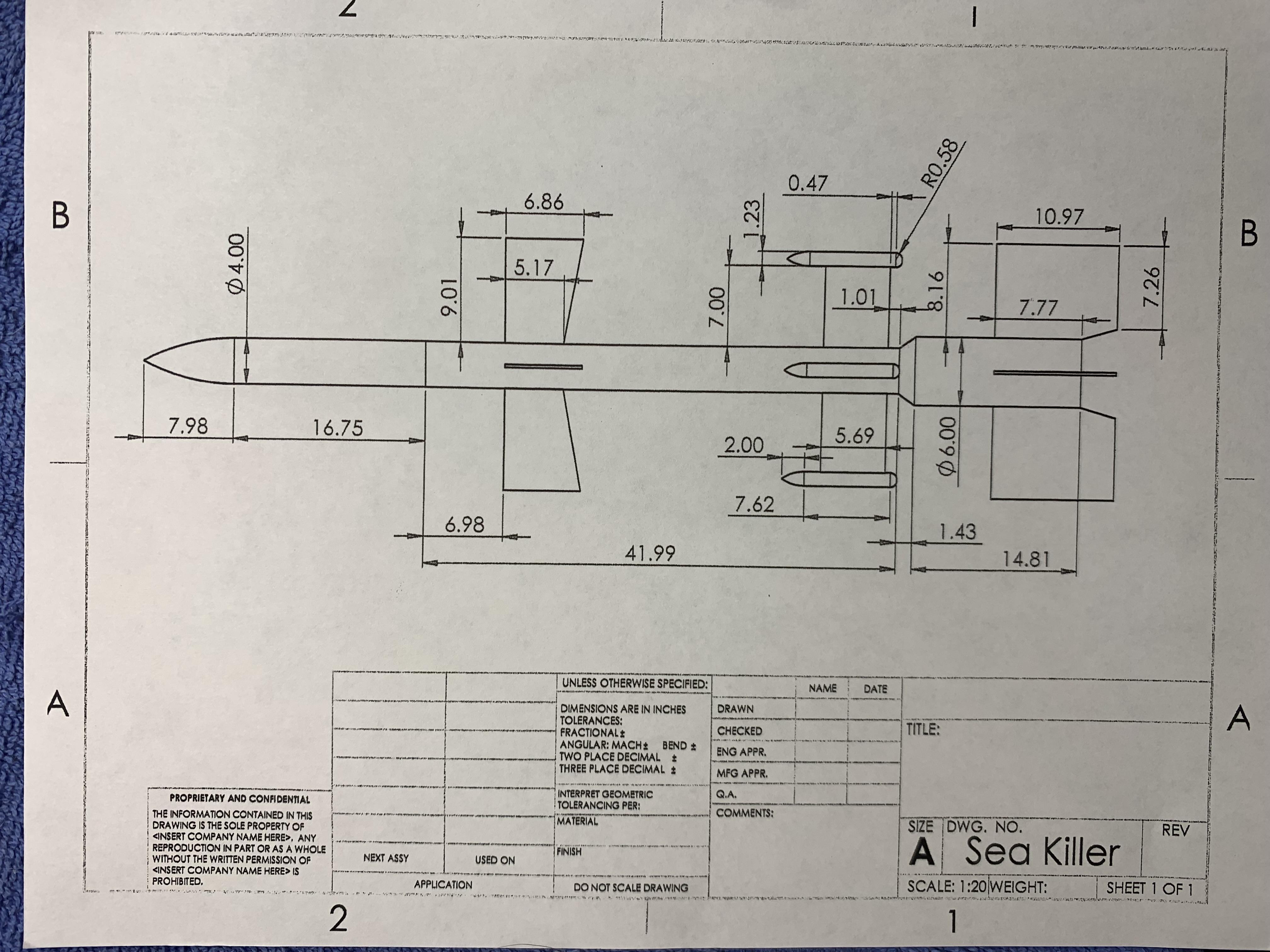

Since I have to finger peck every letter out due to having all the nerves in my hands destroyed, I'm posting some pictures and submittal data of the rocket I first saw back in 1987. Out of all the old HPR magazines I have, I've never found anyone who has done one of these. I've had the goal for the past 36 years to build this, as it's simply the coolest rocket I've ever seen.. Time and money are my 2 biggest obstacles. Several members have done the initial drawings and OR work for me. Chuck @cwbullet got me hooked up with 2 of the Legendary TAP members. Tom Binford, @Rocketjunkie, who was setting off "O" motors back in the Desert in 1992, and Alan Whitmore, Chairman of TRA Motor Testing fame will ensure success for me, as they've about done it all. So here's something to read and look over, Note: the forward fins were reduced about 25%