I like to fly little rockets fast, but I hate building little rockets because it is frustrating fitting everything in a small package. This is more a limit of my building skills than a true limitation of a 38mm tube, but it is what it is. Ive turned to 3D printing for these jobs because it provides control over tiny tolerances, is faster to iterate when a part is just not quite right, and takes advantage of my most abundant time resource (sitting at the pool with nothing to do for 90 minutes 3-5 times a week, i.e. CAD time).

The perfect project to test and illustrate all the ways 3D printing can be applied to a build is the Go Devil 38, and to stress test it, the Loki K627.

The Protagonists:

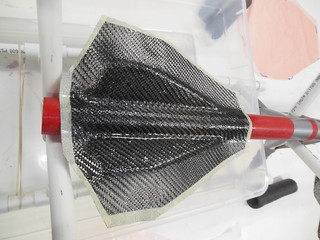

kit_motor by Chris Bender, on Flickr

kit_motor by Chris Bender, on Flickr

As you can see the booster is basically going to be all motor when loaded with the Loki 38-1200 case, but I still need to get some things into the booster. Namely these things:

- Internal Motor Retainer

- Shock cord anchor

- Swivel

- Shock Cord

- At least 2 of coupler (preferably more) and all bulkhead/ejection associated stuff

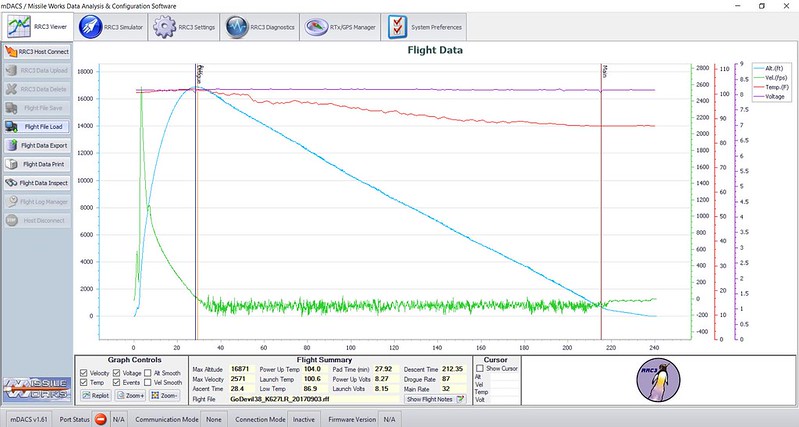

- The electronics bay will be crowded too as an RRC3 powered by a 2S 350 mAh LiPo will need to fit in there.

The payload area will only contain recovery train and the associate 30 TFR thin mill parachute that will function as the main.

The NC will hold an EggFinder mini and 2S 350 mAh LiPo

Note on build technique. I like mechanical attachment of parts whenever possible, so there will be several points where I drill and tap things that could have just been epoxied in, but that is simply personal preference. In my mind that makes it easier to fix things later, but I started this project only planning to fly this rocket once, so I dont know why that mattered to me.

The perfect project to test and illustrate all the ways 3D printing can be applied to a build is the Go Devil 38, and to stress test it, the Loki K627.

The Protagonists:

kit_motor by Chris Bender, on Flickr

kit_motor by Chris Bender, on FlickrAs you can see the booster is basically going to be all motor when loaded with the Loki 38-1200 case, but I still need to get some things into the booster. Namely these things:

- Internal Motor Retainer

- Shock cord anchor

- Swivel

- Shock Cord

- At least 2 of coupler (preferably more) and all bulkhead/ejection associated stuff

- The electronics bay will be crowded too as an RRC3 powered by a 2S 350 mAh LiPo will need to fit in there.

The payload area will only contain recovery train and the associate 30 TFR thin mill parachute that will function as the main.

The NC will hold an EggFinder mini and 2S 350 mAh LiPo

Note on build technique. I like mechanical attachment of parts whenever possible, so there will be several points where I drill and tap things that could have just been epoxied in, but that is simply personal preference. In my mind that makes it easier to fix things later, but I started this project only planning to fly this rocket once, so I dont know why that mattered to me.

Last edited: