Nathan

☢

- Joined

- Apr 19, 2012

- Messages

- 2,230

- Reaction score

- 755

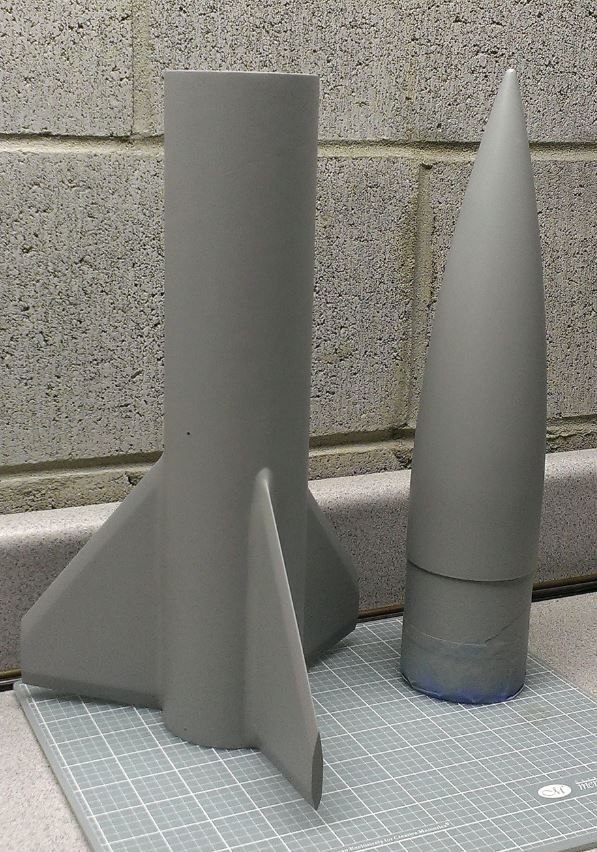

I started building a modified LOC Onyx about a week ago. It will have a 38mm motor mount, 1/4" TTW fins, and 8 oz nose weight. The only parts that I am using from the kit are the airframe tube and the nose cone. Here are some pics of what I've done so far.

I put two dowels through the tip of the nose cone to anchor the nose weight. This pic is after sanding down the dowels and smoothing it out with Bondo.

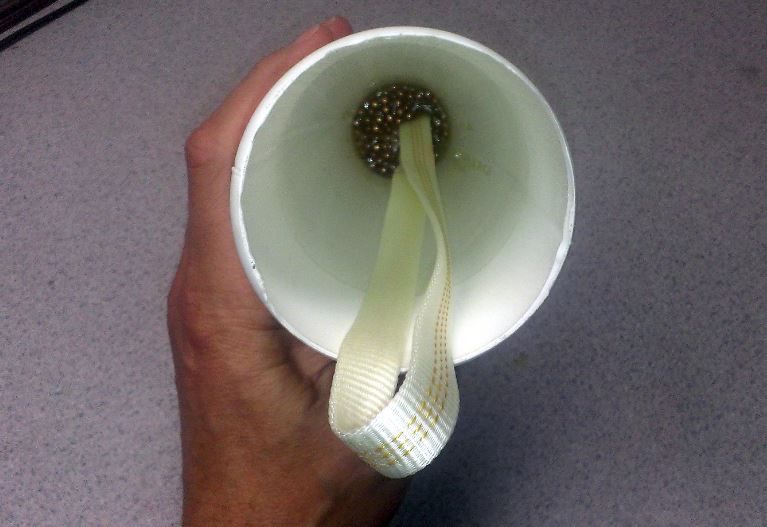

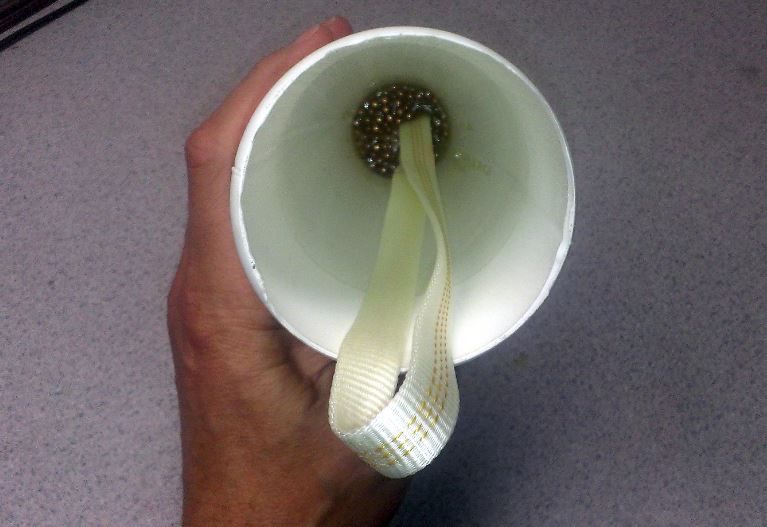

I cut the bottom off of the nose cone so that I could pour in the BBs and epoxy and also because with the big motor mount I need that extra space for the recovery system. I tied a loop of nylon strap around one of the dowels before pouring in the epoxy and BBs.

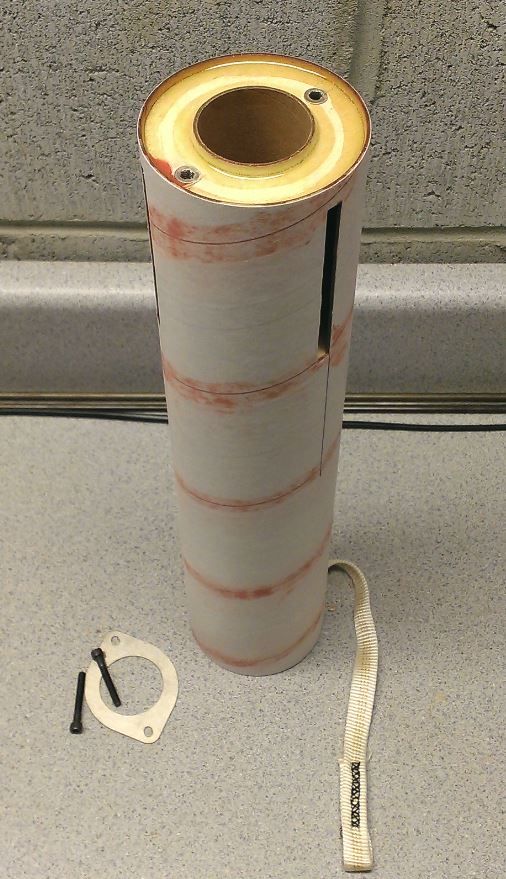

Here is the 38mm motor mount with 3 centering rings. The motor mount is the same height as a 2 grain CTI case.

I'm using an eyebolt in the upper CR as a shock cord anchor. But since my hand doesn't fit down the 3" tube I permanently attached a short nylon strap to the eyebolt, which I will cover with a Nomex sheath. My wife did a nice job sewing the loops on the nylon strap.

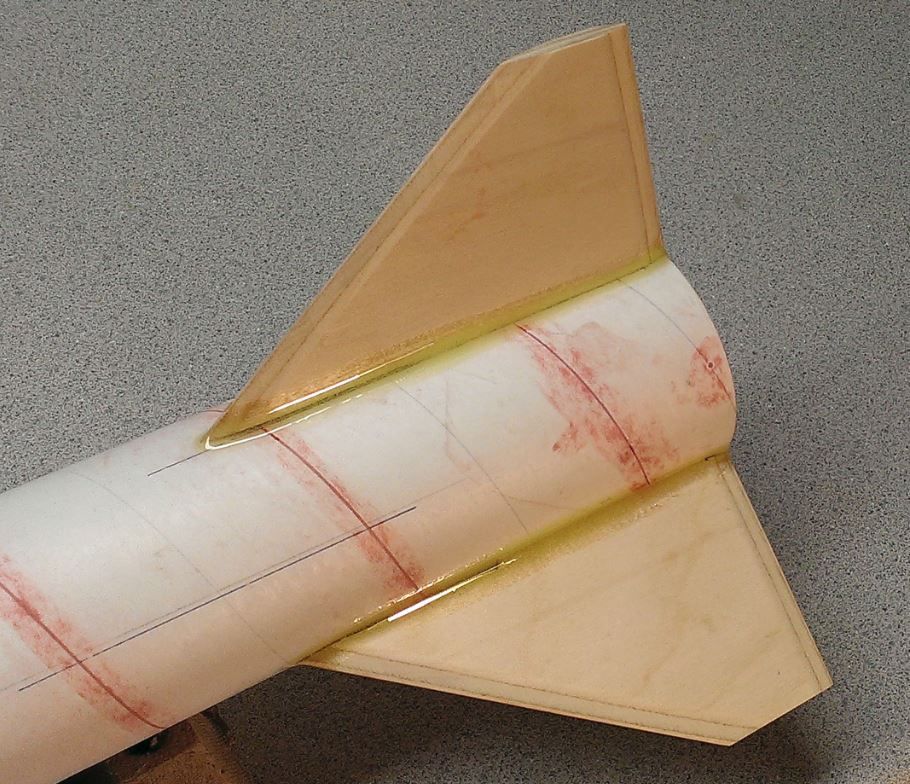

Cut slots for the TTW fins.

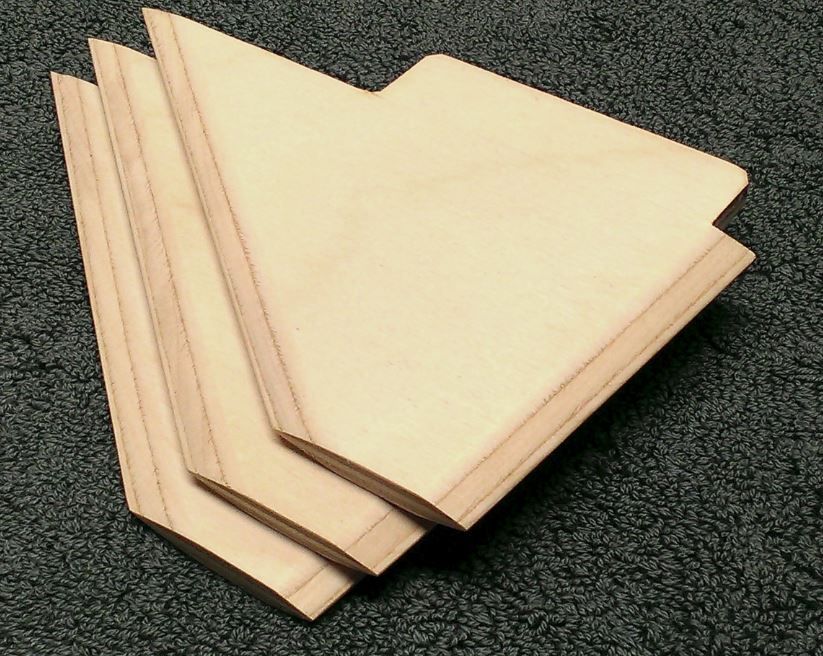

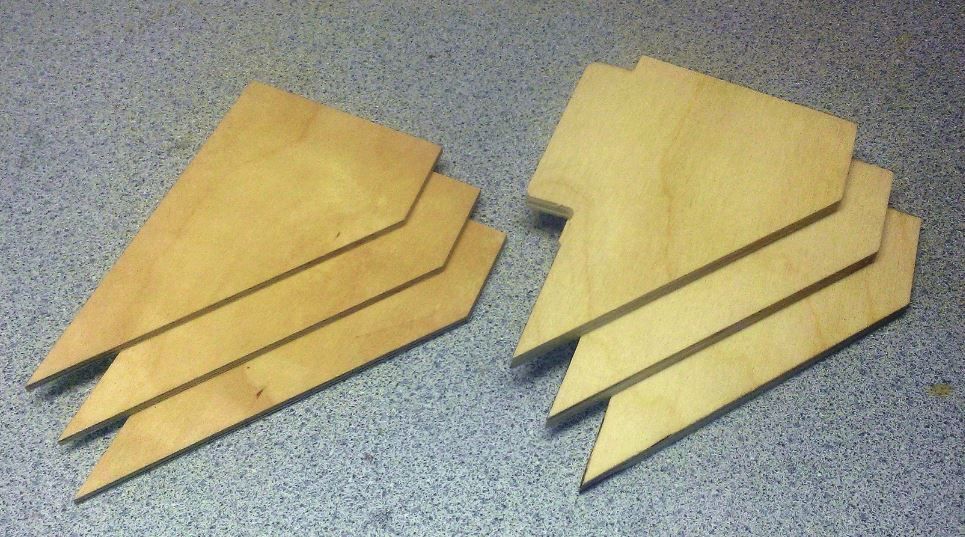

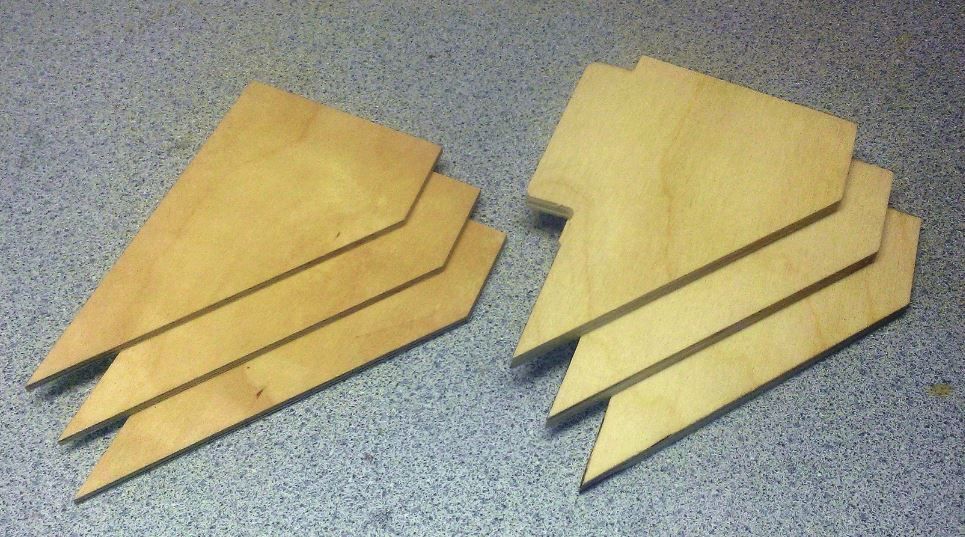

On the left are the 1/8" surface mount fins that came with the kit. On the right are the new 1/4" fins with TTW tabs, which I cut out today. They are the same shape as the original fins.

That's all I've completed so far. I'll update this thread as the build progresses.

I put two dowels through the tip of the nose cone to anchor the nose weight. This pic is after sanding down the dowels and smoothing it out with Bondo.

I cut the bottom off of the nose cone so that I could pour in the BBs and epoxy and also because with the big motor mount I need that extra space for the recovery system. I tied a loop of nylon strap around one of the dowels before pouring in the epoxy and BBs.

Here is the 38mm motor mount with 3 centering rings. The motor mount is the same height as a 2 grain CTI case.

I'm using an eyebolt in the upper CR as a shock cord anchor. But since my hand doesn't fit down the 3" tube I permanently attached a short nylon strap to the eyebolt, which I will cover with a Nomex sheath. My wife did a nice job sewing the loops on the nylon strap.

Cut slots for the TTW fins.

On the left are the 1/8" surface mount fins that came with the kit. On the right are the new 1/4" fins with TTW tabs, which I cut out today. They are the same shape as the original fins.

That's all I've completed so far. I'll update this thread as the build progresses.

Last edited: