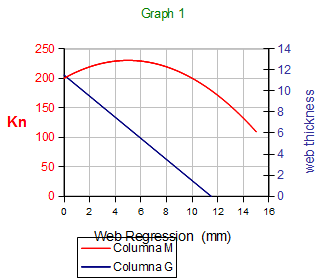

Xinc is the amount x is incremented per interval. The data table breaks the motor burn into 50 intervals so xinc should be 1/50 of your web thickness.

Stay away from PVC. Lots of people building sugar motors started with PVC casings but all seem to move to aluminum. There's a reason for that. If you overpressurize PVC it tends to shatter, creating hazardous shrapnel. Aluminum motors are designed to fail at the threads or snap ring groove creating a much less hazardous situation should you exceed the motors limits. You can get an aluminum snap ring motor for less than $50USD but the peace-of-mind, knowing that you are using a proven motor design, is priceless. One less thing to worry about. Do you know the burst pressure of the tubing you have? The alloy?

I've been where you are. Thirsty for knowledge and eager to make something fly. It is an enjoyable and exciting hobby. But always keep in mind that you are dealing with energetic materials and show the proper respect.

If I were starting out, and my goal was to fly a sugar motor, I would take it in this order:

1) Get a commercial MPR/HPR kit. Something like a LOC IV with a 38mm motor mount. It's not very expensive and assembling you first MPR/HPR kit is very educational. Not quite the same al the LPR kits you may have constructed in your younger years.

2) Get an Aerotech 29mm 40-120 motor. Again, not expensive and the hobby motors assemble in much the same manner as the HP motors should you desire to move up to commercial HP motors later on.

3) Put #1 and #2 together and FLY. It's a lot of fun and you become familiar with launching and ,more importantly,

recovering

rockets SAFELY. You also learn a lot of seemingly minor but important skills. How to calculate the proper ejection delay. How to fold and pack a parachute. Determining stability. The list goes on.

4) Optional- Move up to electronic deployment. Dual deployment with an altimeter is nice but a timer is simpler and will work for this step. This is a personal preference. I don't trust pyrotechnic delays. Even the commercial ones can vary quite a bit. Plus, I like gadgets and electronic deployment gives me some gadget-satisfaction.

5) Get a 38mm 2 or 3 grain snap ring motor. Loki motors can be used with commercial or homemade propellants. I also have some motors made by Ed Romani at Tru-Core and recommend them highly. They are research only and not anodized so the price is a bit easier on the wallet. But the workmanship is top-notch. The graphite nozzles used in snap ring motors last a long time with sugar propellants. I think that the lack of metals in the propellant combined with the lower combustion temperatures result in less erosion to the graphite. Perhaps someone more knowledgeable can confirm/refute this.

6) Melt some sugar. You've been anxious to get to this point. Time to make it happen. This is asuming that you have contacted your attorney/fire marshal/law enforcement/etc and have determined that it is legal to do so. If you have any local rocketeers with motor making experience, seek them out. Get on the Sugpro list. The most experienced sugar motor makers around the world can be found there and they are very willing to help newcomers.

7) GROUND TEST. You need to determine the thrust profile of your homemade motor in order to assure that it will SAFELY get the rocket off the rail/rod. Safety is our #1 priority.

8) Determine the local/national laws and ordinances governing rockets and proceed appropriately. In the US, a rocket meeting the FAA definition of a Class 1 Model Rocket can be launched without a waiver. Above that things get a bit more complicated. The NAR has a good reference filing for a waiver here:

https://www.nar.org/cabinet/waiverinst.html A lightly-built cardboard rocket with a 2 grain 38mm motor can be compliant with Class 1 as long as propellant weight is not exceeded. When you get to class 2 rockets, the regulatory complexity increases. There are a number of amateurs that continue on their own but I suspect that more get their TRA L2 and find an EX friendly club.

The above list is not meant to be all-inclusive. It is what I consider to be the minimum recommend steps to fly a sugar motor and an attempt to point out that the Youtube videos omit lots of important steps. I'm one of the last people that will try to discourage you from making a sugar motor but I can't stress enough the importance of doing it legally and safely. Nobody wants to start their rocketry career in the hospital or behind bars.