Agreed. I wasn't disagreeing with you at all - it's a legit problem that shops do this. My point was that it would be easy enough to use an appropriate impact wrench to remove the lug nuts -and- to install them if it's designed to only spin them until they bottom out without applying a few hundred pounds of force to the lug nuts. Then you could just set it down and torque to spec without going through the hassle of bottoming the lug nut.Yeah, but you still have to torque it to spec after. I don't bring my car to tire shops anymore after having someone basically weld the rim to the hub with a few too many uggaduggas, I drop off the rims and tires now. My point is it's common for tire shops to zap the wheels on with an impact and ignore the torque spec completely leading to needing a breaker bar to get the wheel back off.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

What I did today -instead- of Rocketry.

- Thread starter Charles_McG

- Start date

Help Support The Rocketry Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

KC3KNM

Probably Wrong

Oh yeah, absolutely. I've got a similar setting on my Flex impact that's super handy. I recently had an argument with my girlfriend's brother and father about not using an impact to torque wheels down, so I'm a little touchy still, sorry. "Torque specs don't mean ****" was about where we got with that.Agreed. I wasn't disagreeing with you at all - it's a legit problem that shops do this. My point was that it would be easy enough to use an appropriate impact wrench to remove the lug nuts -and- to install them if it's designed to only spin them until they bottom out without applying a few hundred pounds of force to the lug nuts. Then you could just set it down and torque to spec without going through the hassle of bottoming the lug nut.

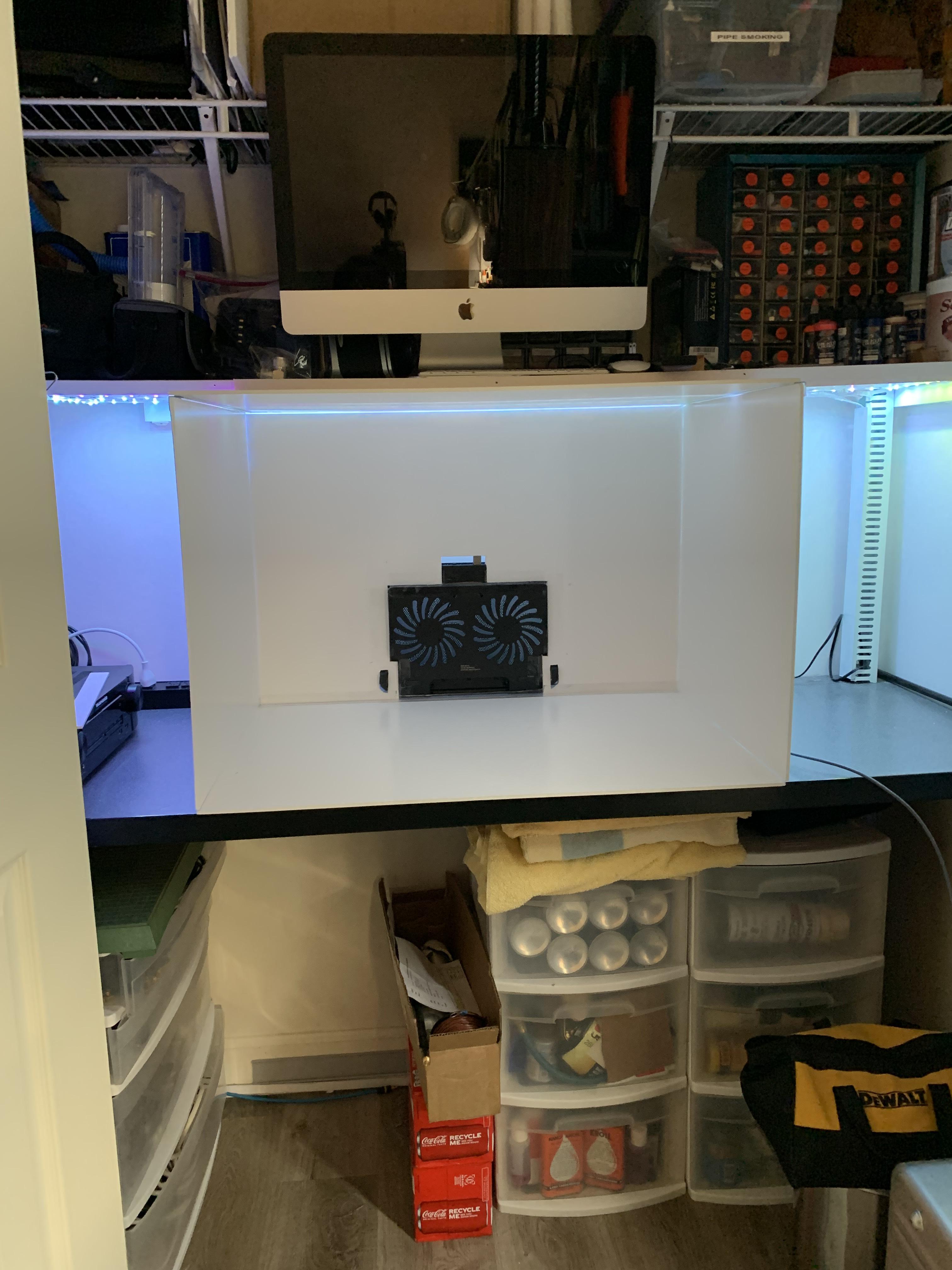

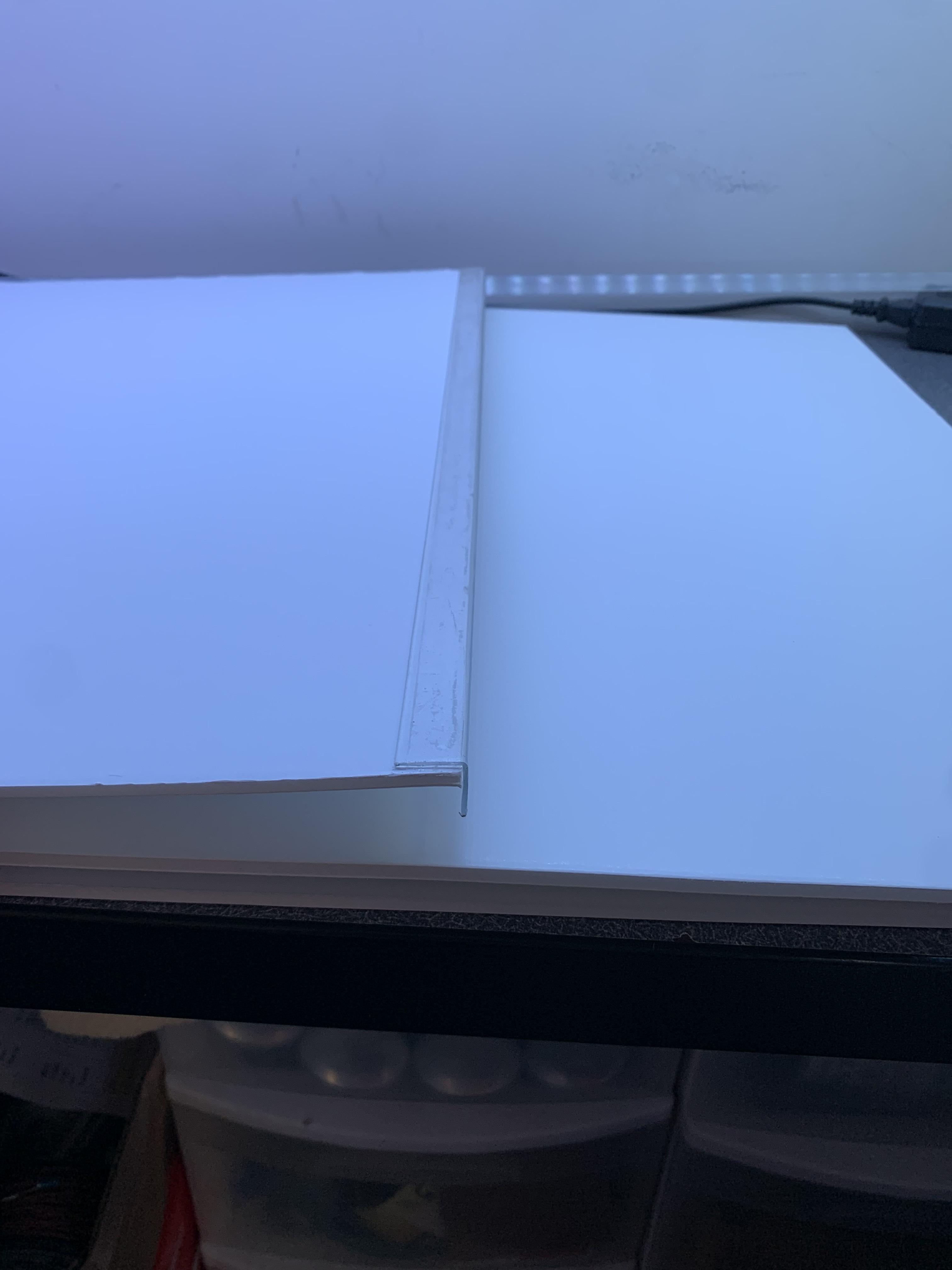

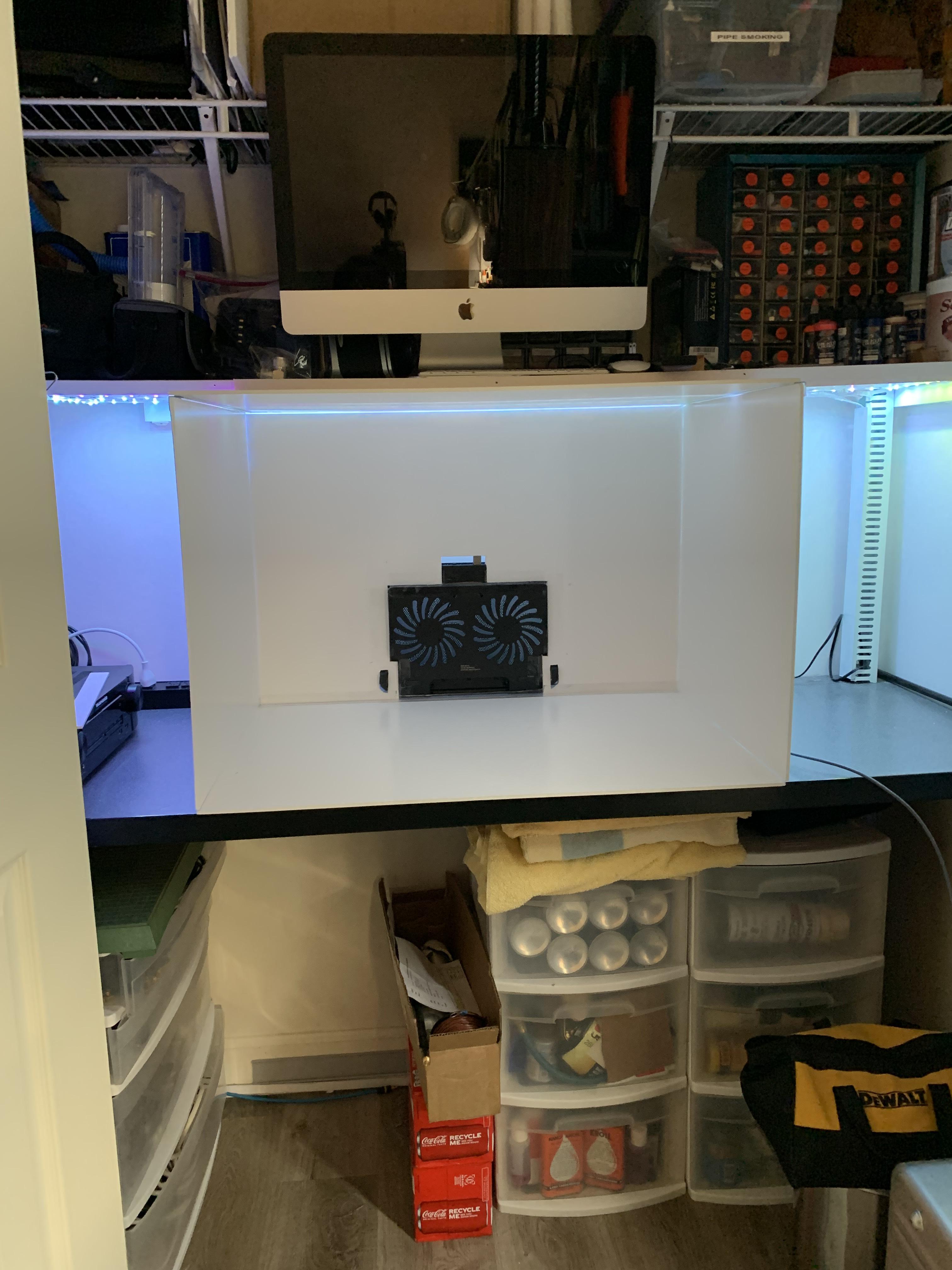

I removed the 16-in LED strip light that was under the Shelf and over top of the tanker desk that I was not using, as it did not put out enough light for the desk. so it will now go into the portable airbrush spray booth that I just put together.

Cape Byron

Rocket kits from the Land of Oz

Plugged the flat tire and pumped it up. Seems to be holding pressure. I hope it's okay, they're Michelins, not even a year old.

Also bought a proper x-form lug wrench and found a 3' piece of pipe just the right diameter to use as an OOOMPH! with the wrench. Tried to remove one of the lug nuts on the tire that's now on the axle. The pipe was needed to get enough leverage...I appreciate the guy who replaced the tire, but apparently he didn't understand that "proper torque" doesn't mean "tighten until you'd need Superman to loosen it."

That insanity really gets me. For one, you're running the risk of yielding or cracking the lug nut. For two, I've been where you were and it's NOT fun. You can limit the torque on an impact wrench, there is no reason for that kind of malarkey. Made your day nearly as fun as mine!

What's behind it? Will you be painting that wall? The pleated filter will stop most of the paint, nearly all, but not necessarily absolutely all, I would think. I would expect the fan to need cleaning once in a while, and some paper on the wall behind couldn't hurt.

now need to get a pleated filter to put in front of the fan and a light.

And now and then the nuts don't break free before the lugs break off. I wouldn't mind the overtorquing quite so much if they'd just take the extra moment to put a dab of grease on the threads.My point is it's common for tire shops to zap the wheels on with an impact and ignore the torque spec completely leading to needing a breaker bar to get the wheel back off.

KC3KNM

Probably Wrong

That carries the added risk of contaminating the mating surfaces between the lugnut and rim, plus from my understanding the torque specs are typically defined by manufactures for dry threads. It's probably fine if you're conscious about it and check in on your lugs from time to time, but I've always heard that refered to as a big no-no. I've never had an issue with locked up lugs when torqued to spec, but I swap them at least once a year for snows so maybe they don't get a chance to really seize up over time.And now and then the nuts don't break free before the lugs break off. I wouldn't mind the overtorquing quite so much if they'd just take the extra moment to put a dab of grease on the threads.

When I've changed my own, I've never abided by the torque spec, since I don't have a torque wrench. I routinely put on a little schmere, or a few drops of oil, or a shot of WD-40, then tightened with my tire star to bottomed plus one good pull. They've never seized, never loosened up on their own, or had any other trouble. I'm not saying it's right, but it has always worked for me.

rharshberger

Well-Known Member

I know that where I buy my tires they use the impact wrench Torque Stick (Stix?) to torque to 100 ft/lbs then use a click type torque wrench to final torque to manufacturers spec. Never had a problem on mine. Lugnuts should be clean and dry before tightening with zero lubricant or anti seize, if anything a bit of threadlocker is allowed, lubricants on a high vibration fastener even propwrly torqued will loosen over time.

rharshberger

Well-Known Member

Depending on how strong you are you may or may not be over torqueing the lug and uneven torqueing is as bad as over/under torqueing. Uneven torque puts one lug under higher tension than the rest which can lead to failure, lug nuts should be evenly torqued. A decent torque wrench will cost less than I motor. I use the Tekton brand sold by Amazon and when they have been checked with a calibration tester (at work, I dont own one) they were consistently within 3-4% of the set value which is good.When I've changed my own, I've never abided by the torque spec, since I don't have a torque wrench. I routinely put on a little schmere, or a few drops of oil, or a shot of WD-40, then tightened with my tire star to bottomed plus one good pull. They've never seized, never loosened up on their own, or had any other trouble. I'm not saying it's right, but it has always worked for me.

Last edited:

I've got a partial roll of brown paper I used to cover my build table when I assembled subwoofers so I'm cutting a piece of that off taping it to the top brace under the Shelf and going to let it hang down to protect the wall from any overspray that might be ejected out the back.What's behind it? Will you be painting that wall? The pleated filter will stop most of the paint, nearly all, but not necessarily absolutely all, I would think. I would expect the fan to need cleaning once in a while, and some paper on the wall behind couldn't hurt.

Laptop cooling fan? Good idea! I made a cardboard spray paint booth and did the ol' air filter in front of fan thing as well, tho they were two cheap box fans cuz...rattle cans. I yank one of those fans and use it for the wind tunnel tooairbrush spray booth-collapsible

now need to get a pleated filter to put in front of the fan and a light.

I needed it to be a shallow of a fan as possible and that fit the bill.Laptop cooling fan? Good idea! I made a cardboard spray paint booth and did the ol' air filter in front of fan thing as well, tho they were two cheap box fans cuz...rattle cans. I yank one of those fans and use it for the wind tunnel too

dr wogz

Fly caster

continued to shovel

(We got about 10" yesterday..)

(We got about 10" yesterday..)

Had a wart removed. Above my lip, right under my right nostril, about 3 or 4 mm. Skipped lunch because I didn't want to keep flexing and stretching it. Slept away the afternoon.

Got the maple sap tubing up at home. Reconfigured a few runs that reduce overall runs of tubing from 7 to 6. Three new trees this year, now they are big enough.

Started rebuilding my MTB fork after I got done with the tubing. Lowers are primed and have one new color on it, no pictures yet. Got the crown painted as well.

Started rebuilding my MTB fork after I got done with the tubing. Lowers are primed and have one new color on it, no pictures yet. Got the crown painted as well.

- Joined

- Aug 25, 2019

- Messages

- 6,184

- Reaction score

- 4,369

Called a hardware store in Tucker to ask if they had 99% Isopropyl Alcohol and how much. Was told they had it at $26 and $36 a gallon. Drove over 45 minutes to Tucker from Covington only to find they didn't have the $26 brand. /sigh

Drove back to Covington, stopping off at the Conyers Horror Fright to pick up a 5-shelf rack. Once I was back, proceeded to work on straightening up the office/man-cave. Got a bit more room to work on rockets, now. [grin]

Drove back to Covington, stopping off at the Conyers Horror Fright to pick up a 5-shelf rack. Once I was back, proceeded to work on straightening up the office/man-cave. Got a bit more room to work on rockets, now. [grin]

That's a handy app.Fretting about the brush pile I posted about earlier really being out before I go to bed, I recalled I had this nice little plug-in for my iPhone that would let me check for "hot spots".

View attachment 557152View attachment 557153

Of course, Bonnie, our feral kitty had to check up on me...

View attachment 557154

Cape Byron

Rocket kits from the Land of Oz

That's a handy app.

Indeed. I could do with that.

Cape Byron

Rocket kits from the Land of Oz

Fun with spanners. Getting some farm gear back into service. I now have a list of parts to order in the morning.

I watched it rain again. We average about 4" a year. I'll bet we have that by the end of the month. After 20 plus years of drought, rain is a good thing. It was an all day rain. Which is the good kind around here. It gives the ground time to let it soak in. Still lots of flooded intersections and low spots. Snow level was down to 4000' last week. Now it's at about 8000'. High of 54F today. When we got here in 91 there was snow all year on Mt Charleston. I thought it was funny. I would be playing golf in July at 110F and could see snow on the mountain. It's 12000' plus some. On this side of the mountain we have a great view. The Vegas side, not so much.

https://www.thermal.com/compact-series.htmlIndeed. I could do with that.

laundry

Cape Byron

Rocket kits from the Land of Oz

Thanks for that!

Went down to the beach on the weekend to catch up with some friends. Also went to a cider distillery. They have the largest underground cider cellar in the world.

Got a behind-the-scenes tour and sampling. Very nice stuff. Loved their scrumpy cider, but bought some of their banksia cider and some apple brandy. Very smooth that brandy. They play Tibetan chimes music all the time, to keep the cider happy. Makes for a nicely different atmosphere down there!

Got a behind-the-scenes tour and sampling. Very nice stuff. Loved their scrumpy cider, but bought some of their banksia cider and some apple brandy. Very smooth that brandy. They play Tibetan chimes music all the time, to keep the cider happy. Makes for a nicely different atmosphere down there!

Similar threads

- Replies

- 2

- Views

- 169