Zeroignite

Well-Known Member

- Joined

- Nov 1, 2013

- Messages

- 1,014

- Reaction score

- 2

Epoxy can be kinda nasty stuff. Getting it on the skin is definitely not good for you, plus it just feels icky. In parts or mixed, it sticks to any surface it comes into contact with, and can be hard to remove from unwanted places. Epoxy is also a key adhesive for rocketry.

So, here's how I do it in a way that's basically guaranteed to not leave any mess.

This is for small-batch 1:1 structural epoxy. Things will be different if you're mixing several ounces of the laminating stuff.

You need nitrile gloves, aluminum foil, and something to mix with. It's also good to have paper towels and isopropanol in easy reach, since that's one of the few things that can clean off epoxy goop.

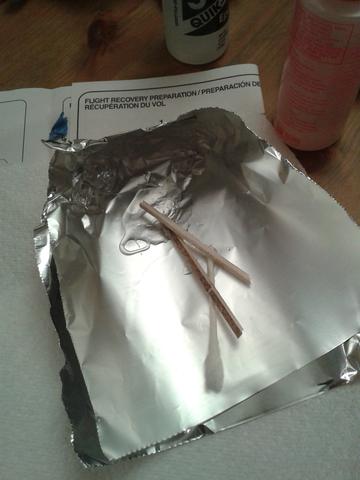

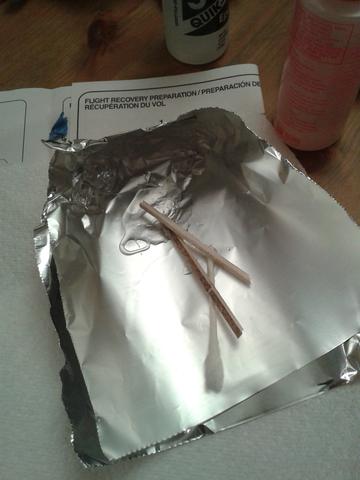

Take some aluminum foil and fold it in half. I like to pinch one corner up into a little boat. For a stir stick, cutting the head off a q-tip gives an even mix and can be a handy applicator.

Put a glove on one hand (likely your dominant side). This hand only comes into contact with places or things epoxy is supposed to get on, and nothing else. Putting the glove on one hand only serves as a useful reminder not to touch anything you shouldn't.

The other hand is free, and should never contact the epoxy at any time.

Put down equal parts of your epoxy of choice. I personally have a lot better success getting the mix ratio right when the resin and hardener come separately, rather than using those single-unit syringe dispensers. In either case, hold the container upside-down for a while first, so the air bubble inside inside floats up and away from the nozzle.

Mix.

How you apply depends on what you're doing. Headless q-tip is pretty great for precise application, but don't underestimate just using a finger when laying down fillets. In any case, remember: glove is for epoxy only, not-glove is never near epoxy. If it starts to gel at all, stop and make another batch --- better to waste a bit then to mess up a project.

Once you're done, put everything you used for application and masking down into the mix boat.

Then, using the gloved hand, pick up the foil and everything else, crumpling it together as you do so.

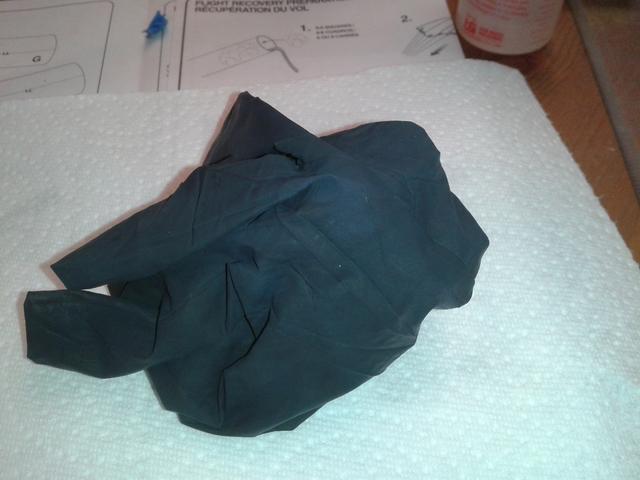

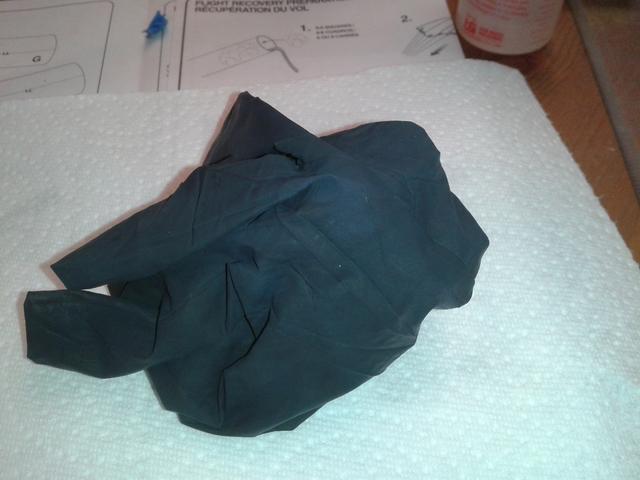

With the clean hand, grab the glove by the cuff and fold it inside-out, moving downwards. Best I can describe the action is it's similar to rolling on a condom.

Once it's folded over completely, the epoxy is entirely contained within a little nitrile baggie! No mess, no drip, no fumes, no skin contact.

So, here's how I do it in a way that's basically guaranteed to not leave any mess.

This is for small-batch 1:1 structural epoxy. Things will be different if you're mixing several ounces of the laminating stuff.

You need nitrile gloves, aluminum foil, and something to mix with. It's also good to have paper towels and isopropanol in easy reach, since that's one of the few things that can clean off epoxy goop.

Take some aluminum foil and fold it in half. I like to pinch one corner up into a little boat. For a stir stick, cutting the head off a q-tip gives an even mix and can be a handy applicator.

Put a glove on one hand (likely your dominant side). This hand only comes into contact with places or things epoxy is supposed to get on, and nothing else. Putting the glove on one hand only serves as a useful reminder not to touch anything you shouldn't.

The other hand is free, and should never contact the epoxy at any time.

Put down equal parts of your epoxy of choice. I personally have a lot better success getting the mix ratio right when the resin and hardener come separately, rather than using those single-unit syringe dispensers. In either case, hold the container upside-down for a while first, so the air bubble inside inside floats up and away from the nozzle.

Mix.

How you apply depends on what you're doing. Headless q-tip is pretty great for precise application, but don't underestimate just using a finger when laying down fillets. In any case, remember: glove is for epoxy only, not-glove is never near epoxy. If it starts to gel at all, stop and make another batch --- better to waste a bit then to mess up a project.

Once you're done, put everything you used for application and masking down into the mix boat.

Then, using the gloved hand, pick up the foil and everything else, crumpling it together as you do so.

With the clean hand, grab the glove by the cuff and fold it inside-out, moving downwards. Best I can describe the action is it's similar to rolling on a condom.

Once it's folded over completely, the epoxy is entirely contained within a little nitrile baggie! No mess, no drip, no fumes, no skin contact.

Last edited by a moderator: