HighFlight

Member

- Joined

- Sep 29, 2014

- Messages

- 20

- Reaction score

- 0

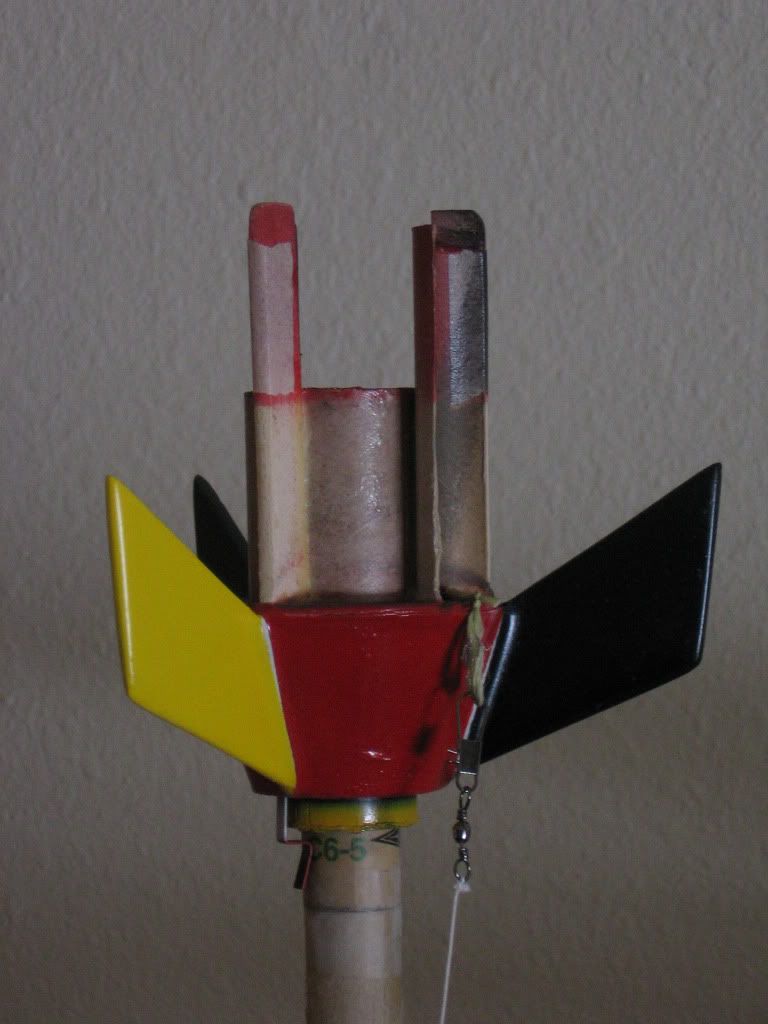

I've got a project in mind for a 2-stage rocket, but without the booster stage. What I mean is, the booster motor would stick out the back of the motor mount by about half the length of the motor, and the 2nd stage motor would kick the booster out, which would fall to the ground, but there would be no reusable booster stage tube & finset that I would have to go find.

Would the upper stage motor char the inside of the motor tube too much?

I did find this thread regarding a motor inside a tube

https://www.rocketryforum.com/showthread.php?63316-Simple-finless-rocket-in-flight

Seems like in the configuration I am intending, the thrust would not be reduced significantly? Has this been done?

Would the upper stage motor char the inside of the motor tube too much?

I did find this thread regarding a motor inside a tube

https://www.rocketryforum.com/showthread.php?63316-Simple-finless-rocket-in-flight

Seems like in the configuration I am intending, the thrust would not be reduced significantly? Has this been done?