dixontj93060

Well-Known Member

- Joined

- Feb 19, 2009

- Messages

- 13,083

- Reaction score

- 45

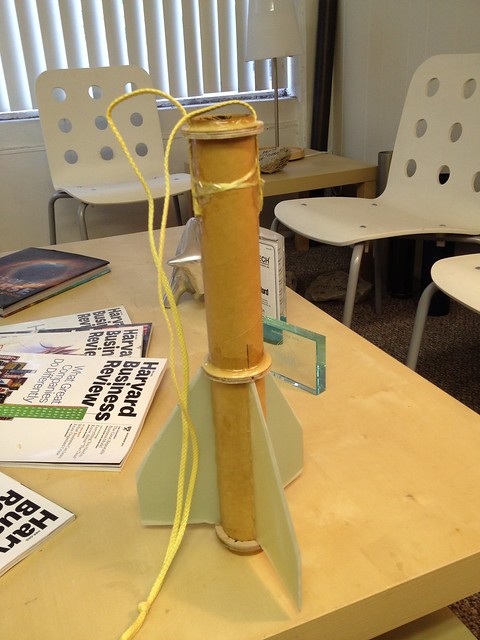

Well after viewing Dan Patell's nice two-stage Formula 54 build it got me back to a project I have had on the "back burner" for some time. I purchased a Blackhawk 29 from Wildman when they first came out. I didn't so much purchase it as a stand alone rocket, but really I thought it would be a sweet sustainer in a two-stage build, not unlike a Loki Dart. And then seeing the Formula 54 fin profile, I thought it would look nice as the booster. So now officially resurrected I pulled the Blackhawk 29 out of the build pile and am assembling extra parts for my bins to do the booster.

Last edited: