George why not just start a build thread?

Well, I'm torn between a separate build thread, and the "groupthink" in this thread. Of course, a separate build thread could be a "GroupBuild" thread.

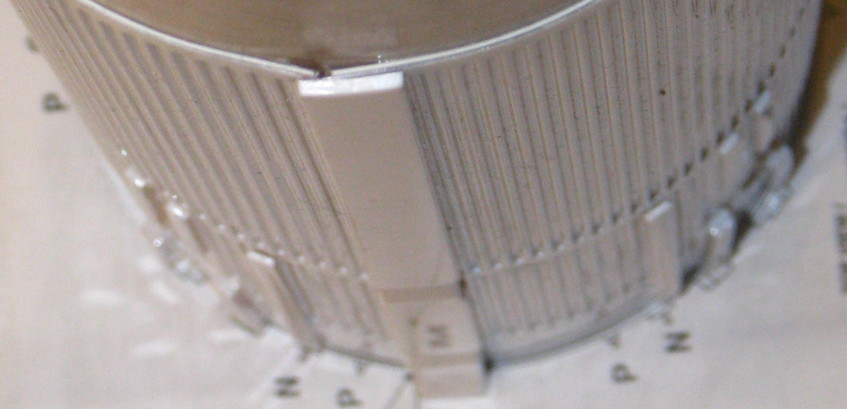

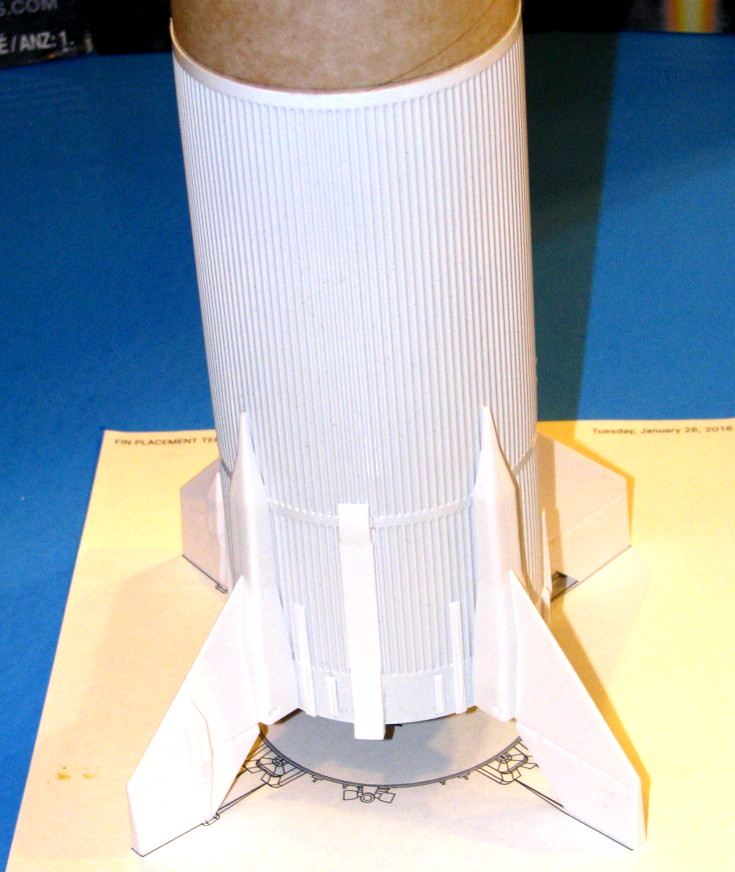

But here is an example of something of general interest. Now, for one, I should have tried to apply more adhesive along the two edges, if I had tried I'd have probably sprayed some excess into a cap to capture it in liquid form and carefully use a small brush to apply by hand. Anyway, the seam was OK at the time I applied the system tunnel. I was surprised to find that the long system tunnel was not aligned in the middle of the seam. It's aligned mostly to the seam, with only one edge touching one corrugation top on the left. I came back later to find this:

It has pried out a bit. Now perhaps if I had used an elastic bandage or something to hold the whole thing compressed. But, anyway, what I will try to do to fix it is to carefully apply a bit of CA underneath and press together.

For a future model, I might just apply the tunnel one corrugation to the left, so the tunnel can act more like an external splice. Although if I can get a better bond along the edges to begin with, it would not matter as much.

That is not the only thing but one example. So does that seem suited for a separate build thread or this thread?

But, I am taking a LOT of photos of various steps, and if I posted lots of those in this thread it could get pretty gnarly. So, perhaps a separate thread and note the occasional odd stuff here?

I would love to see you post now as you go George but if this would hurt your

Joy of the build, forget it.

Well, I never enjoy building rockets.... but you can't fly 'em if you don't build 'em (unless RTF).

Hmm, how can I phrase this.... I'm not UNenjoying this as much as other builds?

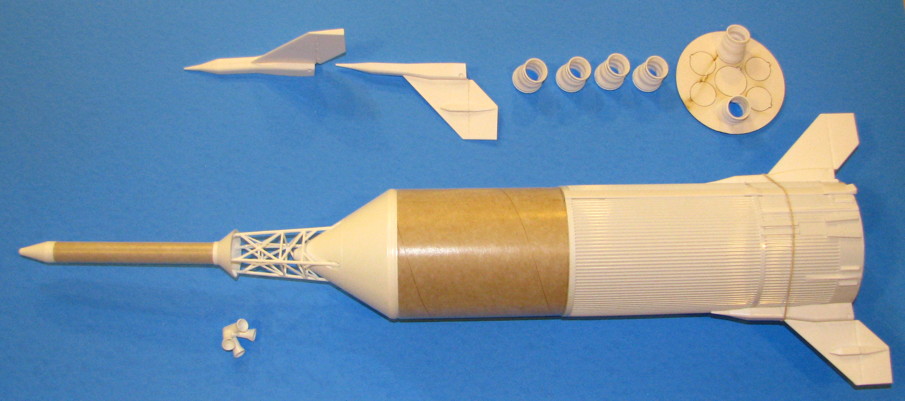

And man it sure makes a difference to be building a Little Joe-II of this size, from a kit, and not a scratch-built one.

I'm excited regardless. And on some level I am having fun building it even if it's more subconscious than anything else. There is probably only ONE other kit that I could get this excited to build, and I'm not going to say what so as not to jinx it.

And indeed right now there are some other projects that need attention.... but regardless I'm finding the time to build one anyway.

So, this is such a UNIQUE situation. Yes, I'm reliving building a 1/45 Joe much like I did in 1975. But unlike 1975... I actually know so much about the real rocket now. So I appreciate it on that level too, and can share some info most don't know as much about.

So, more of the fun in this is sharing the info. And also, I am taking the approach of building this as a "fun" model to sport fly. I'm not trying to make it judge-worthy. And so the occasional "oops", ah, no big deal. But also can learn from the first one to try to do better next time.

Likewise, not putting a lot of time into the build, I won't be as leery of simply sport flying it. I never sport fly my contest-worthy sport models (Well, my X-1 was a unique exception, a sport model I entered at NARAM for the heck of it and due to mission points and DQ's by others it moved from 5th to 1st).

I do want to note that it was Tom Beach who compiled the massive amounts of raw data starting in 1983, then shared so much of it with me in 1989 that I began to draw it up and we collaborated..... without internets or even Compuserve (I wasn't online at all till after the data project was over... we were mailing floppy disks back and forth, I'd draw mot of it, he'd review, make notes, sometimes his own tweaks to the drawing files, etc. And he made a few drawings of his own. Oh if only I had e-mail back then, Tom already did).

So, whatever level of knowledge I have about the Little Joe-II will never be as much as Tom knows.

https://georgesrockets.com/GRP/Scale/DATA/Tom.htm

- George Gassaway

- George Gassaway