TheNewGuy

Well-Known Member

- Joined

- Apr 24, 2017

- Messages

- 48

- Reaction score

- 1

Previous thread with general questions about the kit: Blackhawk 38 Questions

I'm currently working on a Wildman Blackhawk 38. So far I've epoxied the fins to the lower airframe (will post pics later), and attempted painting. I'm also working on a 3D printed electronics bay for the coupler, and my own Arduino based GPS tracker. The altimeter will be a Raven 3.

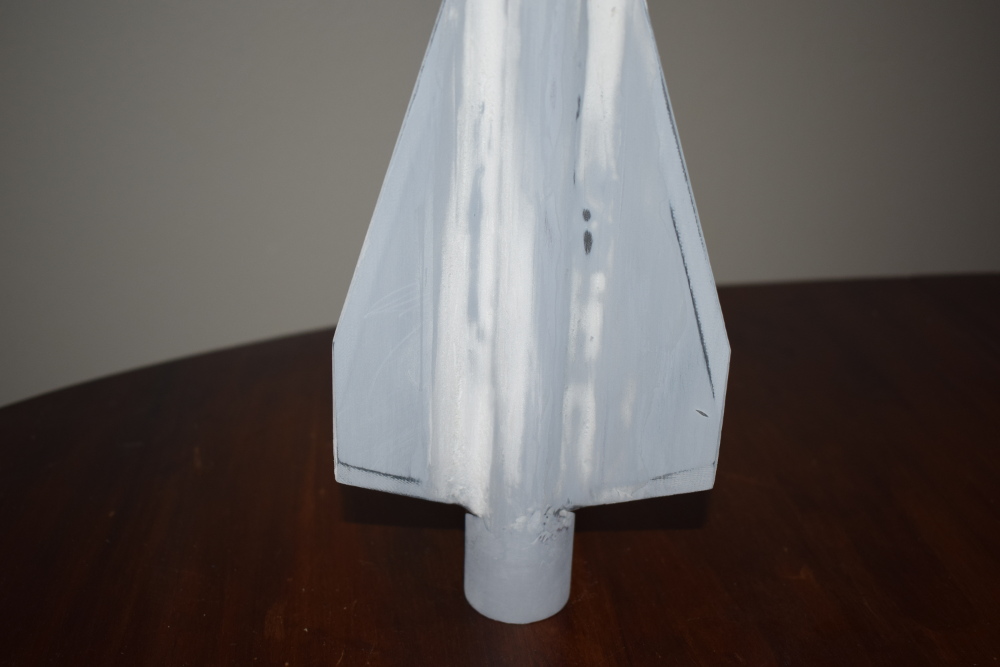

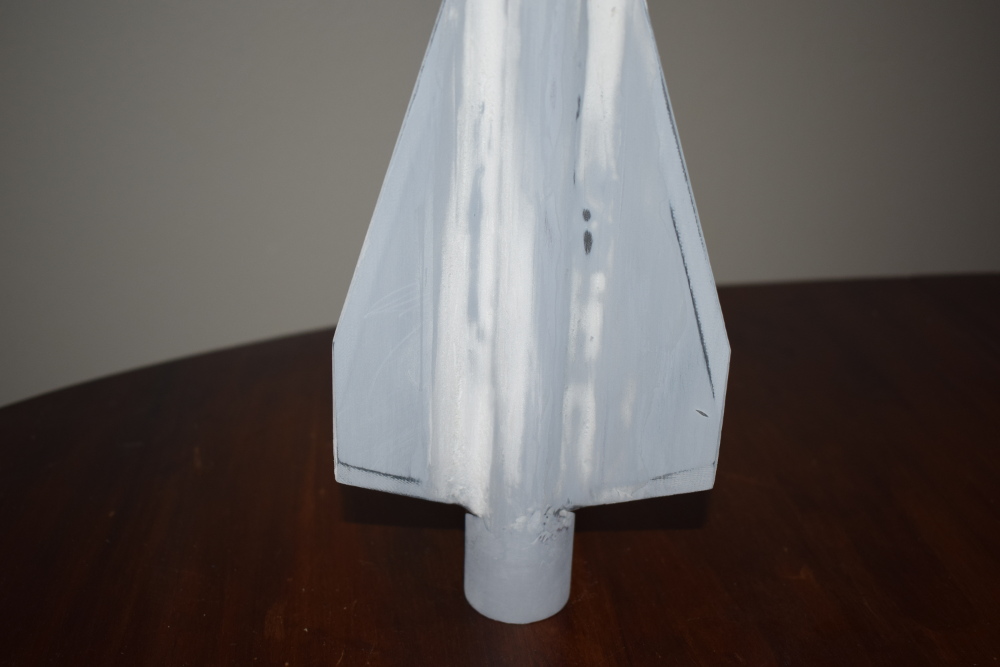

The fillets on the booster section were ok, but not great. I pulled the masking tape off too late, and on others I completely forgot to put the masking tape all together.

After a ton of sanding, I had fillets that structurally sound, but are not perfect at all.

So I went ahead and sprayed primer on everything (the last pic below shows everything I'm using). I let it dry for about 17 hours, then sprayed black paint on the nose cone and payload tube.

Here is where things started to go down hill.

After letting both parts sit for 15 minutes, I do a check of the parts and see drips on both payload tube and nose cone. Nose cone is really bad, payload tube only has one drip at the top (see pictures below).

I went to home depot and got 800 grit sandpaper, and started sanding away at the nose cone. I started to realize that the drips are only becoming more and more pronounced, as well as the primer starting to show through the black paint in certain areas.

Question: What's the best way to fix the nose cone and payload tube?

When painting the rocket, I put some plastic sheets on the wall and floor in the corner of my kitchen. Now, anytime I walk in my kitchen the bottoms of my socks are black. I've tried cleaning it up with cleaner and even acetone, but with no luck.

I'm going to spray another coat of primer, and hope it stays.

Overall, I'm really excited to fly this rocket, but not enthusiastic about the way finishing is going. Advice is much appreciated.

Introduction

I'm currently working on a Wildman Blackhawk 38. So far I've epoxied the fins to the lower airframe (will post pics later), and attempted painting. I'm also working on a 3D printed electronics bay for the coupler, and my own Arduino based GPS tracker. The altimeter will be a Raven 3.

Painting

Painting has not been fun.The fillets on the booster section were ok, but not great. I pulled the masking tape off too late, and on others I completely forgot to put the masking tape all together.

After a ton of sanding, I had fillets that structurally sound, but are not perfect at all.

So I went ahead and sprayed primer on everything (the last pic below shows everything I'm using). I let it dry for about 17 hours, then sprayed black paint on the nose cone and payload tube.

Here is where things started to go down hill.

After letting both parts sit for 15 minutes, I do a check of the parts and see drips on both payload tube and nose cone. Nose cone is really bad, payload tube only has one drip at the top (see pictures below).

I went to home depot and got 800 grit sandpaper, and started sanding away at the nose cone. I started to realize that the drips are only becoming more and more pronounced, as well as the primer starting to show through the black paint in certain areas.

Question: What's the best way to fix the nose cone and payload tube?

When painting the rocket, I put some plastic sheets on the wall and floor in the corner of my kitchen. Now, anytime I walk in my kitchen the bottoms of my socks are black. I've tried cleaning it up with cleaner and even acetone, but with no luck.

Lower Airframe

I've been trying to fill in some of the waves and lines in my fillets with HobbyLite Filler, but I'm not fond of this filler at all. It's really hard to apply to the rocket, and I'm not 100% confident it's going to stay on the primer.I'm going to spray another coat of primer, and hope it stays.

Overall, I'm really excited to fly this rocket, but not enthusiastic about the way finishing is going. Advice is much appreciated.

Pictures

Last edited by a moderator: