Started my "BIG" build this week, an Ultimate Darkstar Sharon bought for me two years ago at Airfest. She just did it so she could buy her Gizmo XL and not feel guilty, but that's another story.

We will be building these over the summer, hopefully for the next Airfest in September.

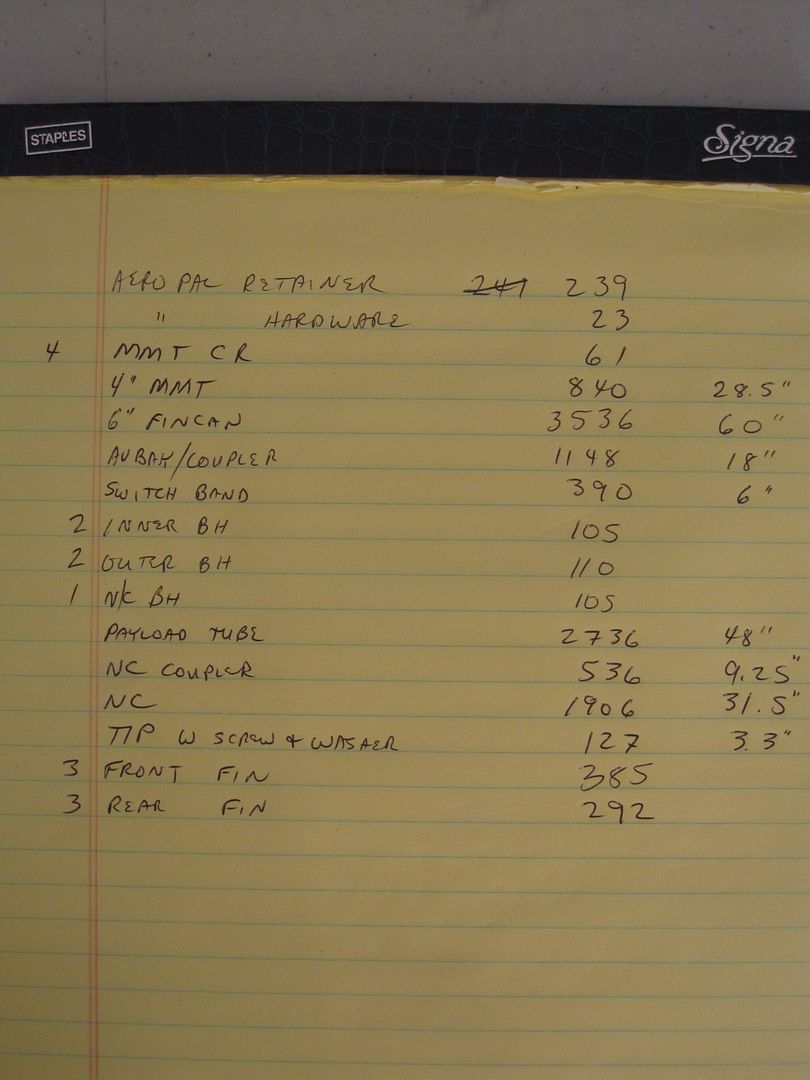

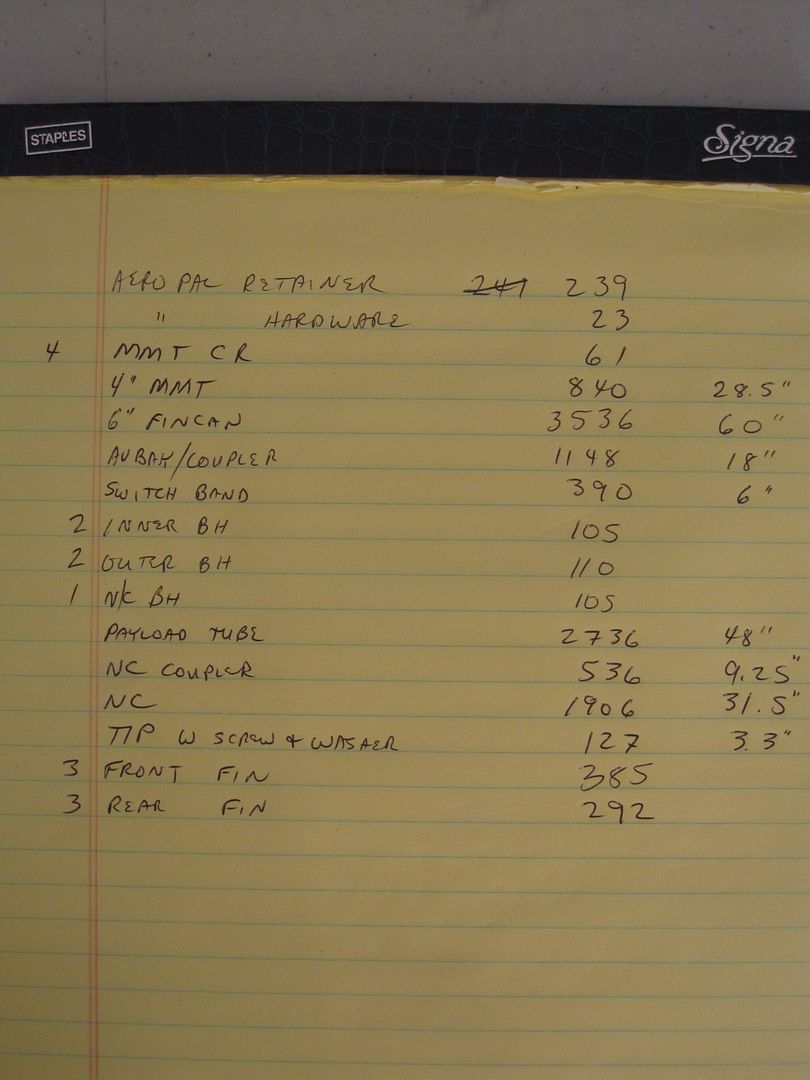

I started out by laying all the parts out and weighing them:

These numbers may change a bit, I might be trimming down the 6" switch band and 18" avbay/coupler, maybe a few other things....

About 32 lbs. without epoxy and recovery. I have a Cert. 3 XL for the main and a 24" drogue. Probably add a few more pounds of epoxy, since I plan to inject internal fillets too.

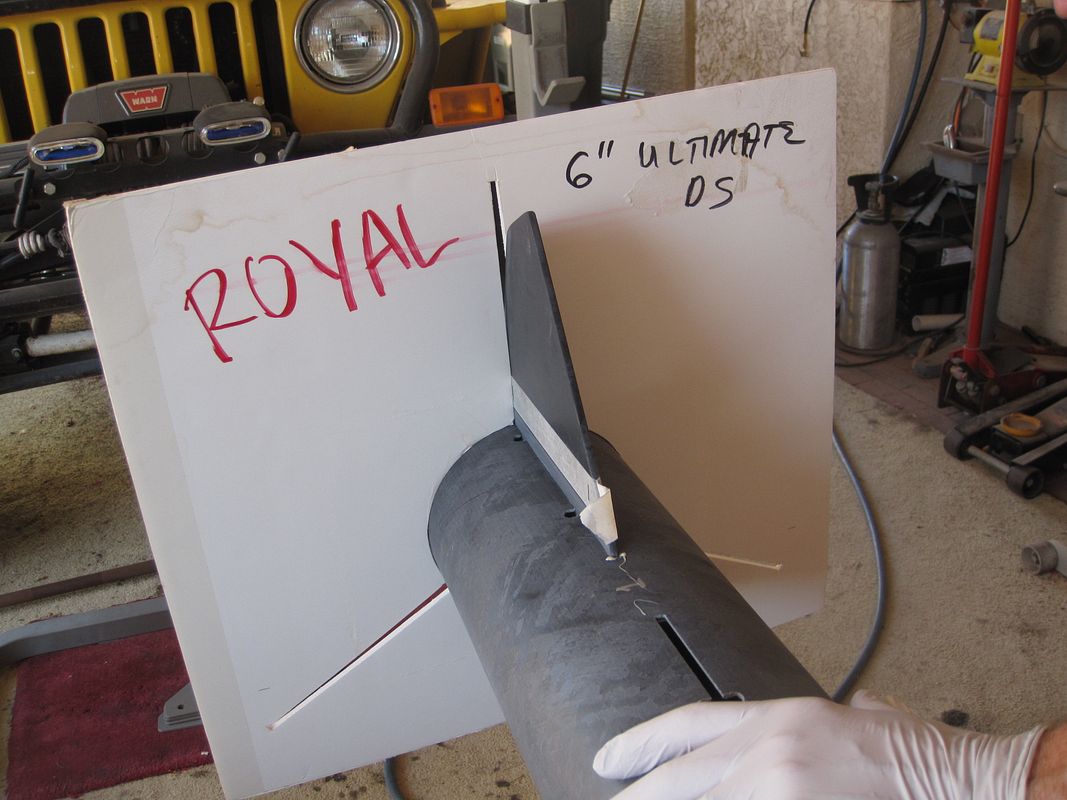

I took the motor mount tube outside to sand it down, along with the centering rings and fins to fit them on the MMT:

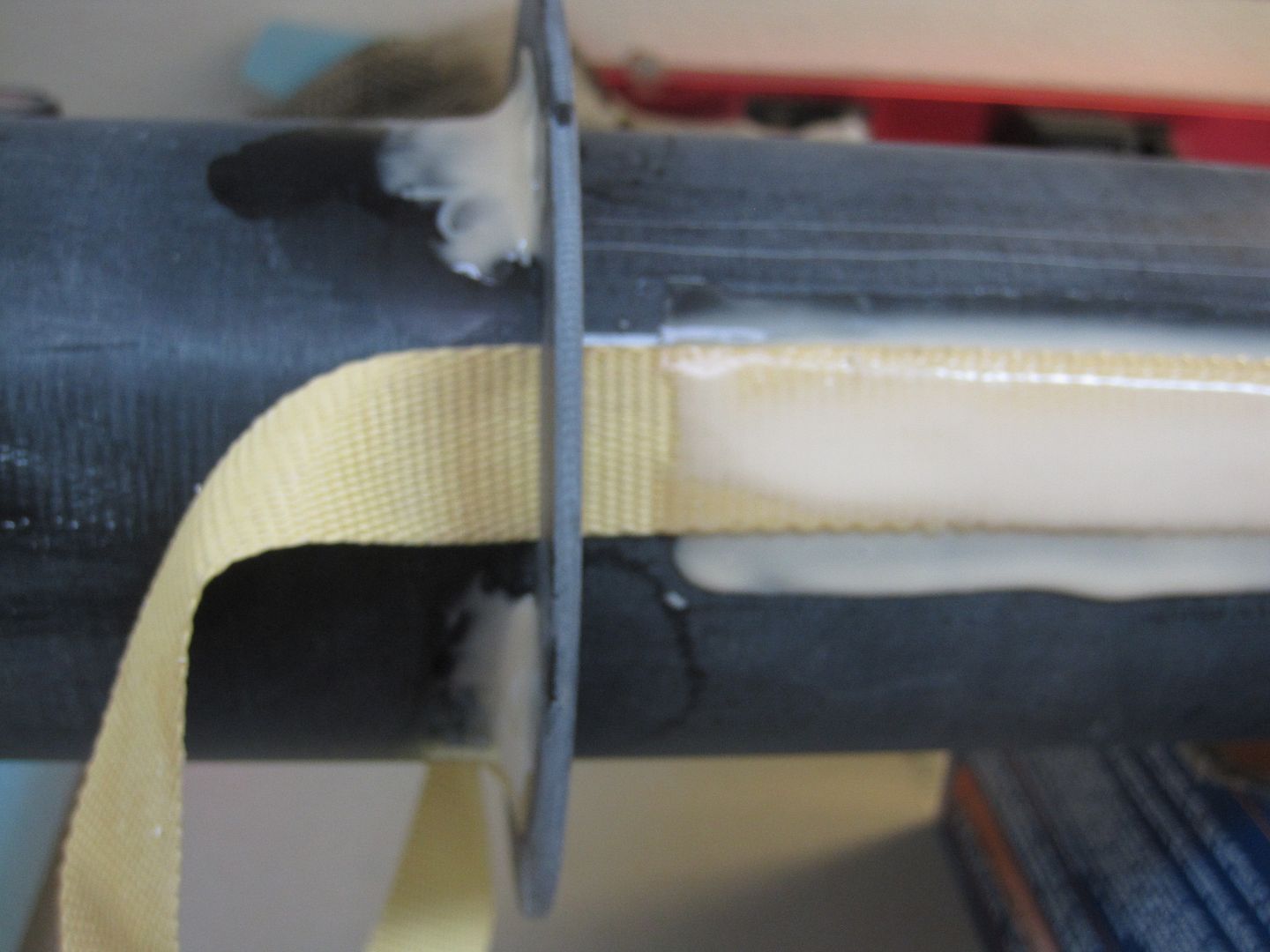

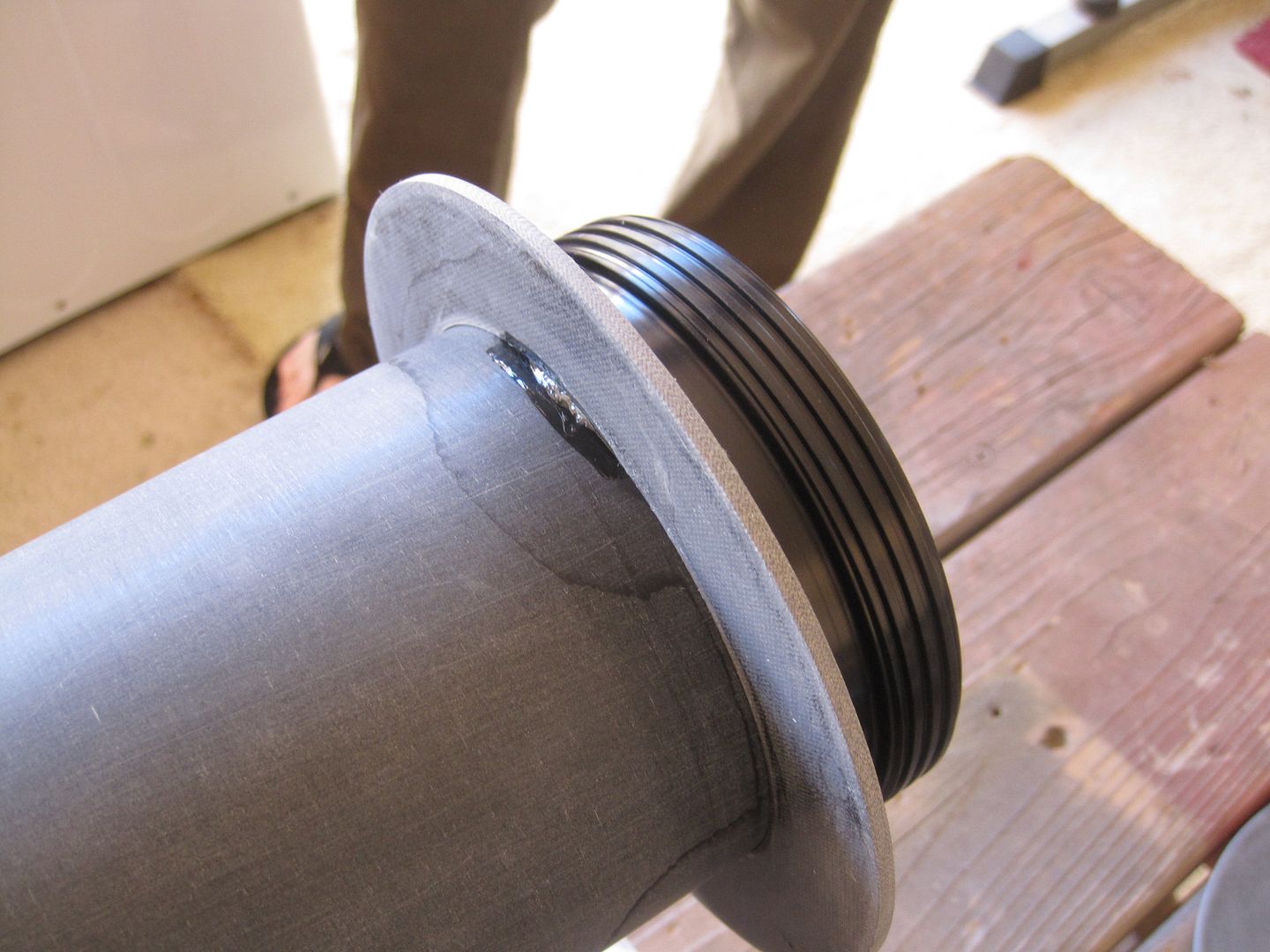

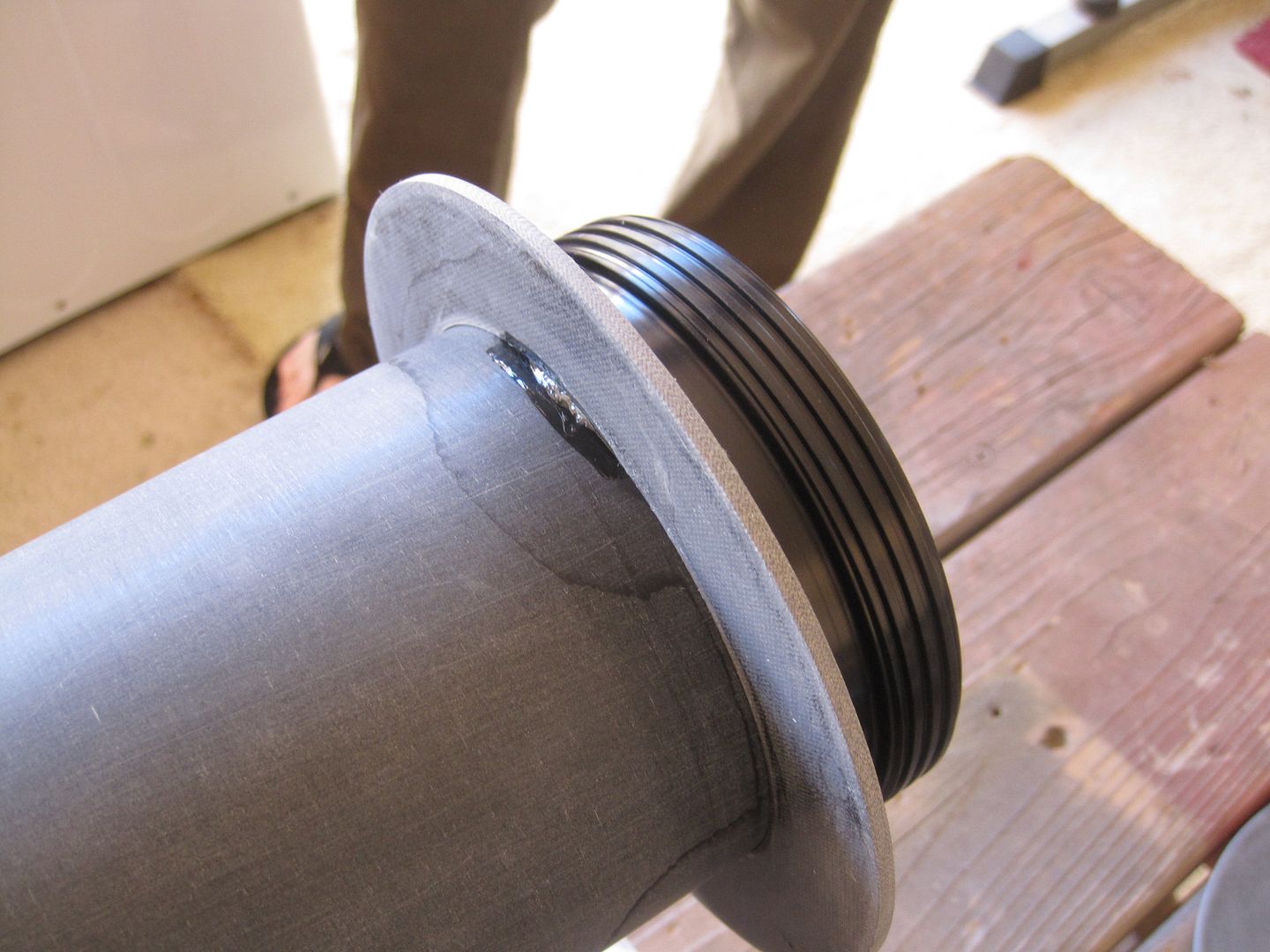

Starting at the bottom and working my way up, I pulled a CTI 4 grain casing out of our stash to mount the Aeropac retainer to the aft CR:

I tacked the aft CR onto the MMT with some medium CA:

Then I pressed the retainer up against it and drilled my first hole. The 8-32 screws that hold the retainer on need to be cut off flush with the CR so the fins can fit flush to the ring, so I'm tapping threads to the holes, one at a time:

Screw the first one in, and drill another hole at the opposite side:

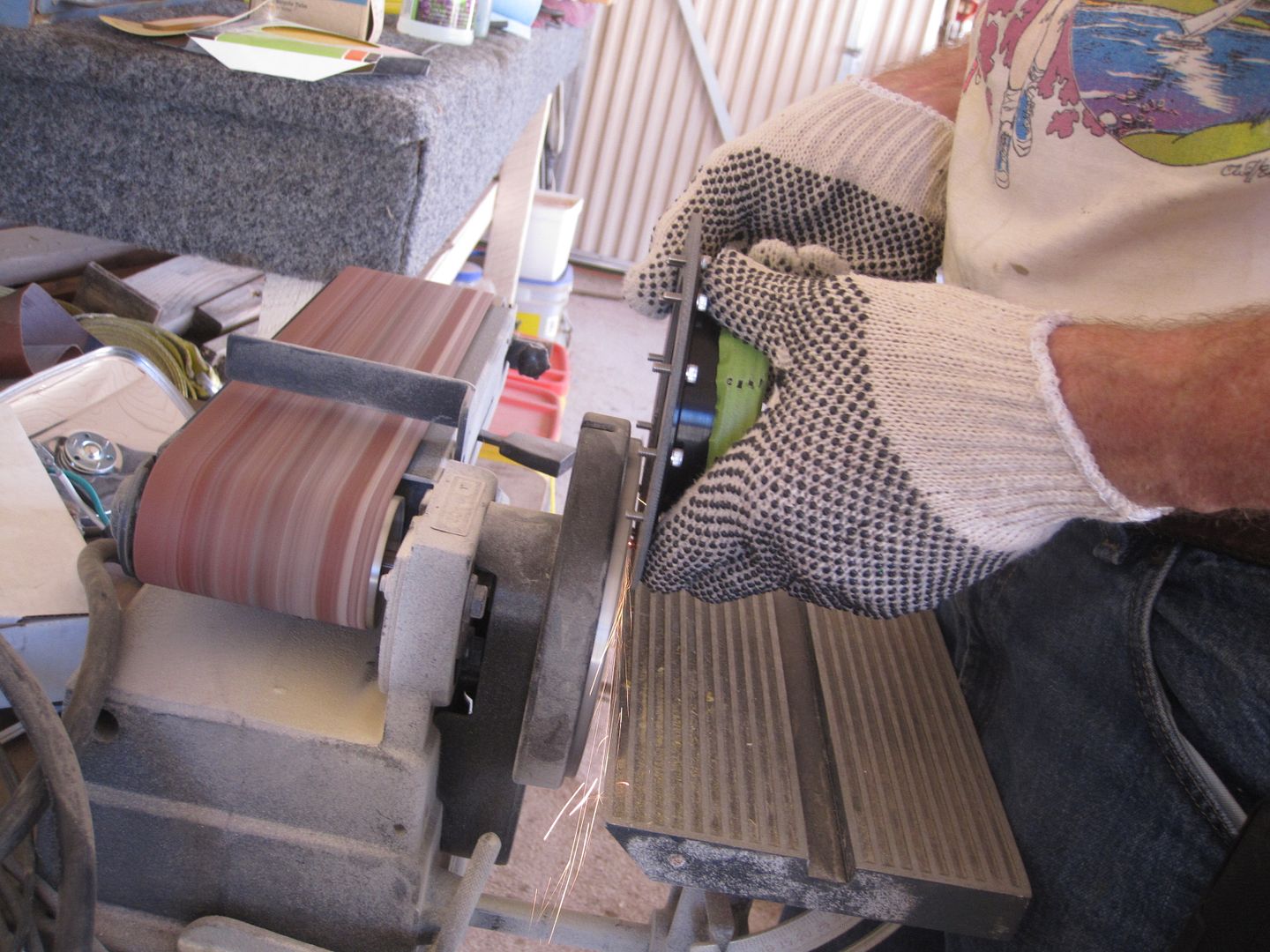

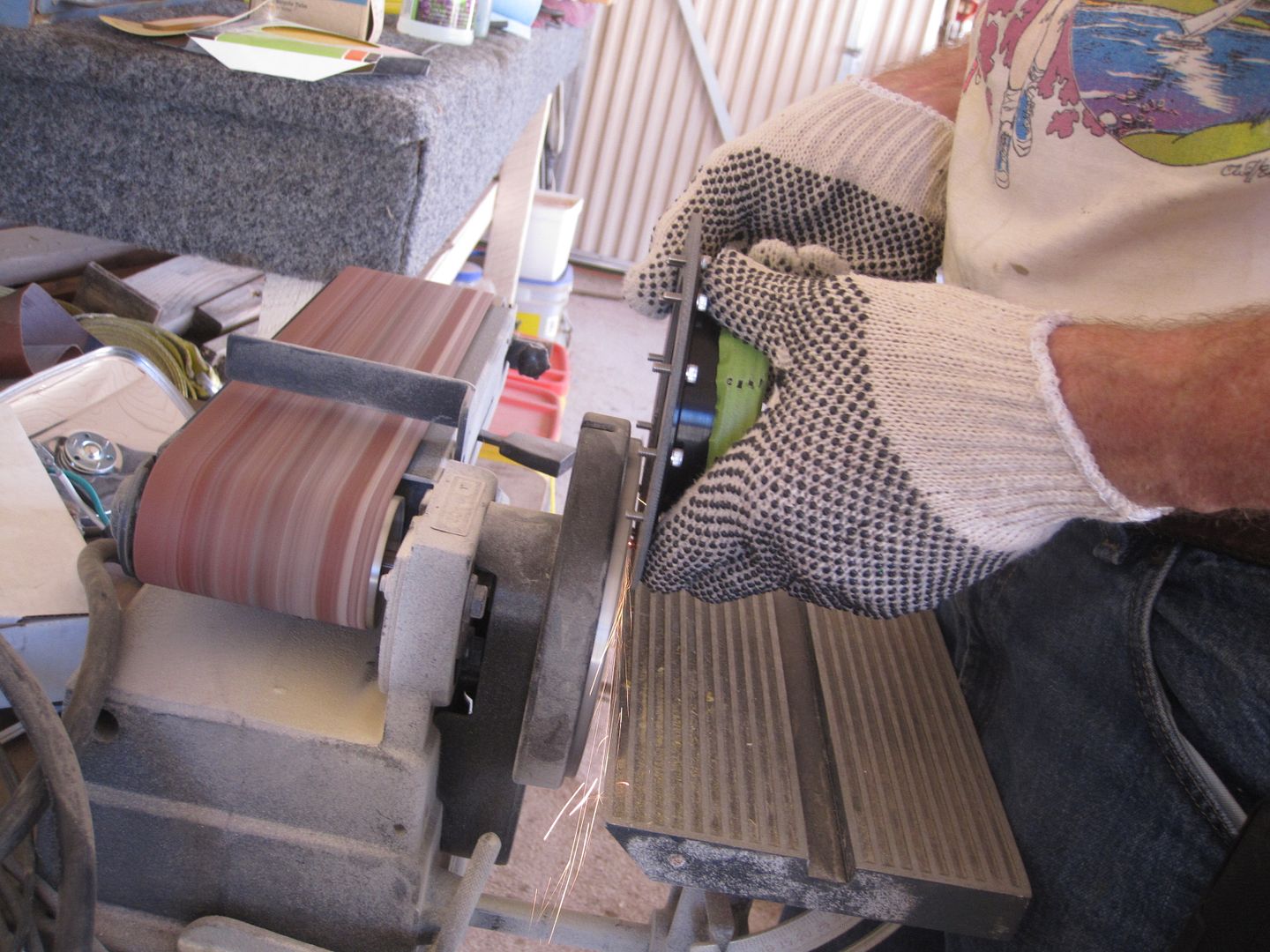

Tap that hole and tighten in the second screw to hold the retainer in place, and you can drill out the rest of the holes. After I got that task done, I removed the CR and retainer and started removing the ends of the screws that stuck through the CR. I first tried sanding them off with my bench sander:

That didn't work too well, so I switched to my grinder:

Ended up using the dremel:

Re-installed the rear CR and added the top CR to mark the fin slots. This took some sanding, not only on the CR's, but the fincan also. Pulled out my handy new cordless sander from Harbor freight and started in on the fincan:

Sanded down where the rings would fit against the fincan, and also the fin slots, which tend to bow in when cut:

This went pretty quickly, the new tool did the job well:

First attempt at inserting the MMT didn't work at all, so I went back and sanded the fincan some more and sanded the forward CR:

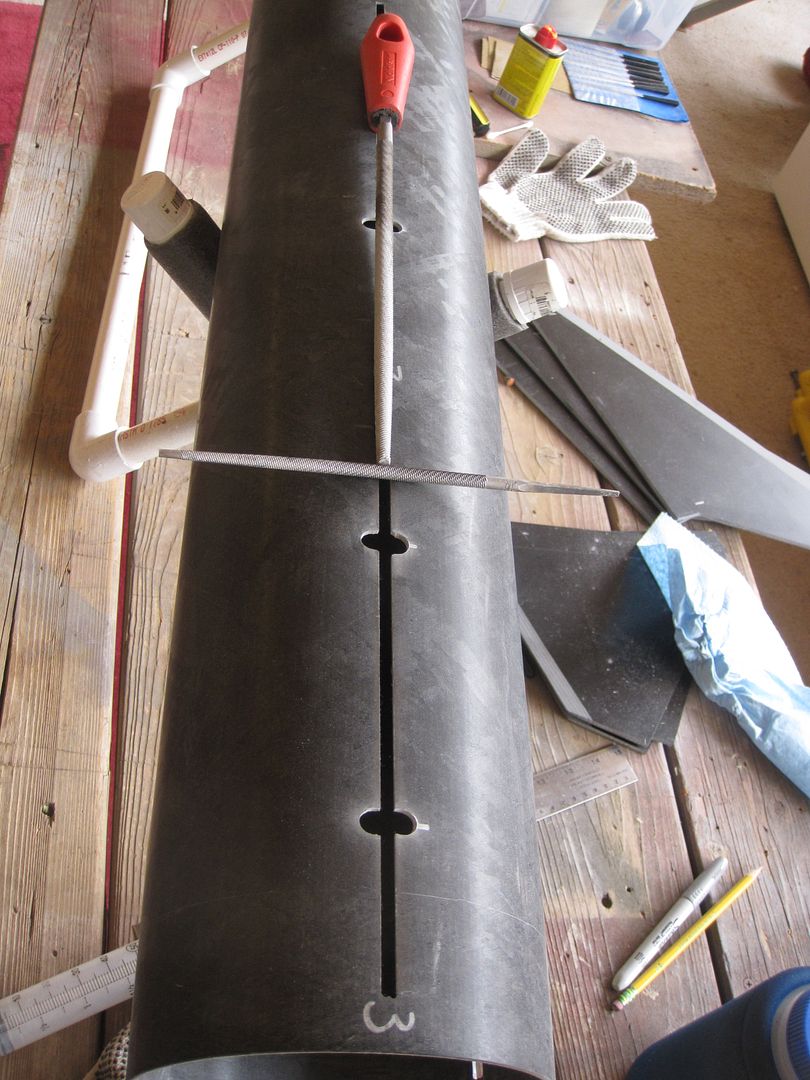

Once I got the MMT installed, I used my olfa knife to mark it where the fins would go:

I marked the fin slots with a silver sharpie, and marked an index mark on the aft CR:

It took Sharon and I both to pull the MMT back out, a 6" tube with long slots bows in quite a bit. Sharon was holding the fincan down while I wiggled the MMT back out. Here are the slot markings on the MMT:

We started working on fitting the next CR in, but tacking it in with CA glue was just not working. Decided to take a break, and when we checked the thermometer, it was 104* in the work area. I think we will pick this back up later....

We will be building these over the summer, hopefully for the next Airfest in September.

I started out by laying all the parts out and weighing them:

These numbers may change a bit, I might be trimming down the 6" switch band and 18" avbay/coupler, maybe a few other things....

About 32 lbs. without epoxy and recovery. I have a Cert. 3 XL for the main and a 24" drogue. Probably add a few more pounds of epoxy, since I plan to inject internal fillets too.

I took the motor mount tube outside to sand it down, along with the centering rings and fins to fit them on the MMT:

Starting at the bottom and working my way up, I pulled a CTI 4 grain casing out of our stash to mount the Aeropac retainer to the aft CR:

I tacked the aft CR onto the MMT with some medium CA:

Then I pressed the retainer up against it and drilled my first hole. The 8-32 screws that hold the retainer on need to be cut off flush with the CR so the fins can fit flush to the ring, so I'm tapping threads to the holes, one at a time:

Screw the first one in, and drill another hole at the opposite side:

Tap that hole and tighten in the second screw to hold the retainer in place, and you can drill out the rest of the holes. After I got that task done, I removed the CR and retainer and started removing the ends of the screws that stuck through the CR. I first tried sanding them off with my bench sander:

That didn't work too well, so I switched to my grinder:

Ended up using the dremel:

Re-installed the rear CR and added the top CR to mark the fin slots. This took some sanding, not only on the CR's, but the fincan also. Pulled out my handy new cordless sander from Harbor freight and started in on the fincan:

Sanded down where the rings would fit against the fincan, and also the fin slots, which tend to bow in when cut:

This went pretty quickly, the new tool did the job well:

First attempt at inserting the MMT didn't work at all, so I went back and sanded the fincan some more and sanded the forward CR:

Once I got the MMT installed, I used my olfa knife to mark it where the fins would go:

I marked the fin slots with a silver sharpie, and marked an index mark on the aft CR:

It took Sharon and I both to pull the MMT back out, a 6" tube with long slots bows in quite a bit. Sharon was holding the fincan down while I wiggled the MMT back out. Here are the slot markings on the MMT:

We started working on fitting the next CR in, but tacking it in with CA glue was just not working. Decided to take a break, and when we checked the thermometer, it was 104* in the work area. I think we will pick this back up later....