- Joined

- May 8, 2010

- Messages

- 1,285

- Reaction score

- 261

Well here's an itch that took twenty years to scratch

View attachment WasatchCover.pdf

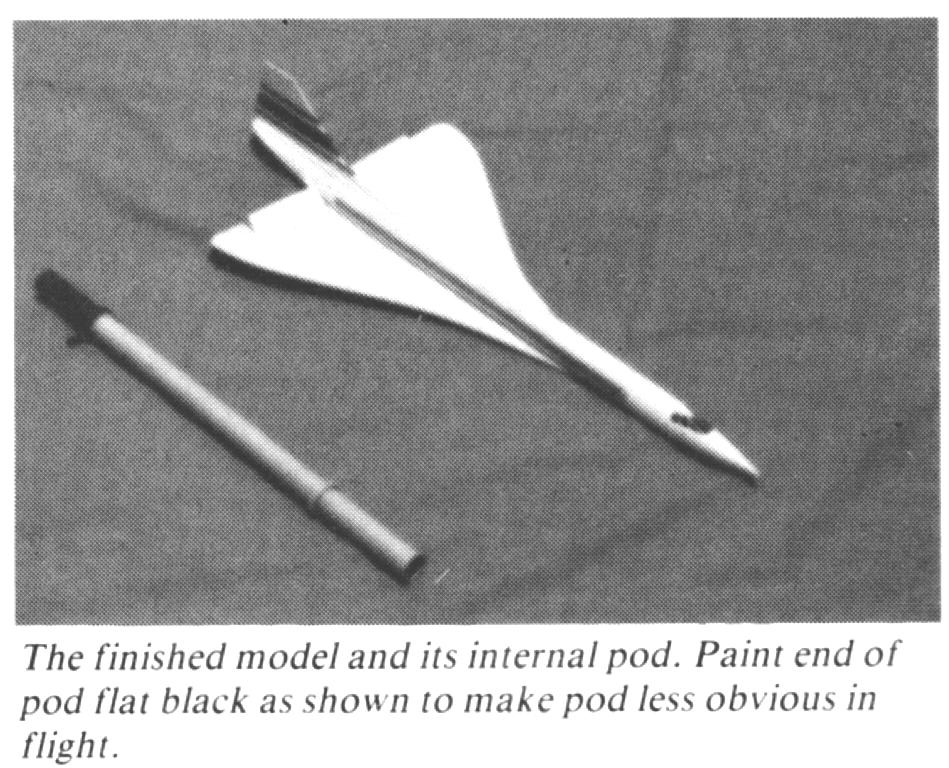

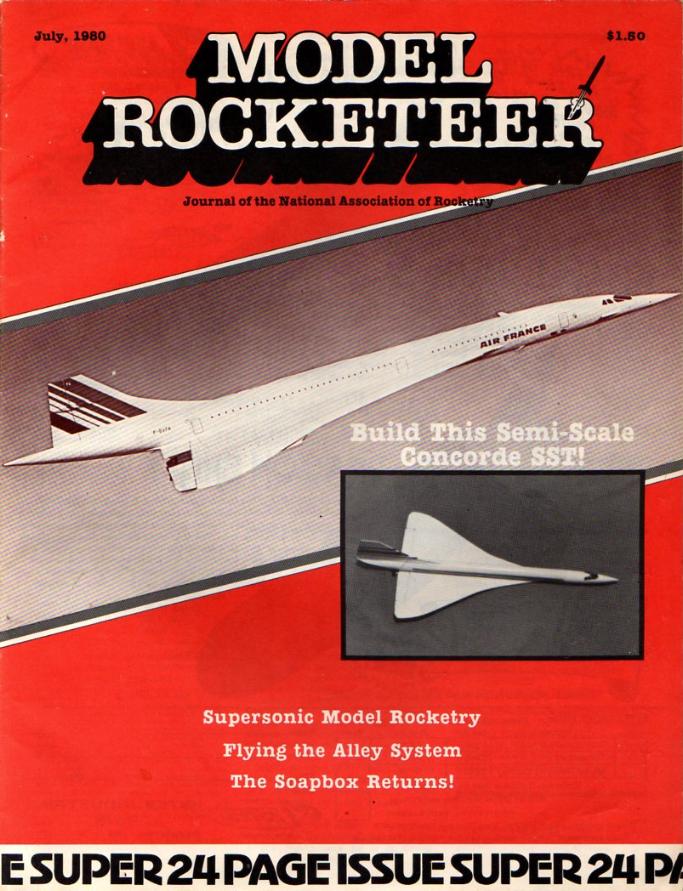

Back in the day (early 90's) when I first got heavy into HPR I bought many a kit and motors from Gary and Sydney Price who ran High Sierra Rocketry in it's second iteration. Gary also had his own line of kits under the name Wasatch Rocketry. Most notable were the gliders of which there were two versions, a BT-60 based model with 24mm power and a BT-80HD version with 29mm power. I never actually saw one in the flesh back then, but Gary had given me a catalog with them in it and I always wanted one.

About 10 years back I saw one of them on Ebay and bought it. Since then it has been chilling in the garage. Recently I decided that it would look better built than in the bag, so I started the build. Before I get into that too much, I do want to mention that this appears to not be an original design by Gary Price but rather an upscale of an earlier, smaller SST design by George Gassaway. Also, I would like to thank TRF member AstronMike for his advice on this project.

View attachment WasatchCover.pdf

Back in the day (early 90's) when I first got heavy into HPR I bought many a kit and motors from Gary and Sydney Price who ran High Sierra Rocketry in it's second iteration. Gary also had his own line of kits under the name Wasatch Rocketry. Most notable were the gliders of which there were two versions, a BT-60 based model with 24mm power and a BT-80HD version with 29mm power. I never actually saw one in the flesh back then, but Gary had given me a catalog with them in it and I always wanted one.

About 10 years back I saw one of them on Ebay and bought it. Since then it has been chilling in the garage. Recently I decided that it would look better built than in the bag, so I started the build. Before I get into that too much, I do want to mention that this appears to not be an original design by Gary Price but rather an upscale of an earlier, smaller SST design by George Gassaway. Also, I would like to thank TRF member AstronMike for his advice on this project.

Last edited: