- Joined

- Mar 27, 2013

- Messages

- 22,535

- Reaction score

- 14,942

One thing that I've developed a fondness for is a boat tail. Prime Examples, the Binder Design Velociraptor my downscale builds, I needed to cut nosecones down to create my boat tails... Here's how I did it.

Using progressively larger Centering rings locked together by friction with a scrap of body tube (omitted from the image below) I created a cutting guide for my Xacto blade.

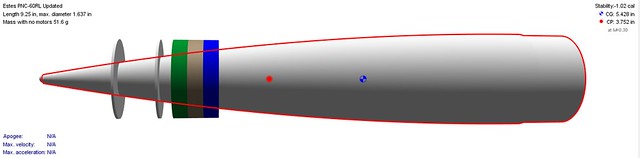

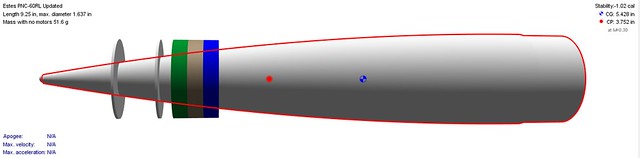

Visualized here is a jig for cutting enough of the tip off of a PNC-60RL that will accommodate a BT-50 motor tube. The green/tan/blue Centering rings are actually the same size (CR-5055), I changed the color to distinguish each CR from the next (the extra CRs (green/tan) keep the end one (blue) from getting cockeyed). The middle white CR would be a CR-2055, and the outer white CR is a CR-555. When these are held inside a scrap of BT-55 body tube, they will keep the end CR (blue) firmly locked in place so that you will cut a circular segment, and not an ellipse.

I use the back of an Xacto blade that has had the tip broken off to scrape a groove into the plastic. I make multiple, light passes, to deepen the cut until the tip can be removed. I don't use a saw, or the Xacto's cutting edge, as these can quickly allow a mistake to become magnified to the point where it will become easily visible.

After cutting the tip away, I clean up the edge with sandpaper. I also verify that the intended motor tube will fit inside the hole make sure that when a motor is installed that it won't bind before gluing the motor tube in place.

I use a similar method to groove the tips of nosecones (just not cutting as deep) for paint separation lines (simulated radomes, etc.)

Using progressively larger Centering rings locked together by friction with a scrap of body tube (omitted from the image below) I created a cutting guide for my Xacto blade.

Visualized here is a jig for cutting enough of the tip off of a PNC-60RL that will accommodate a BT-50 motor tube. The green/tan/blue Centering rings are actually the same size (CR-5055), I changed the color to distinguish each CR from the next (the extra CRs (green/tan) keep the end one (blue) from getting cockeyed). The middle white CR would be a CR-2055, and the outer white CR is a CR-555. When these are held inside a scrap of BT-55 body tube, they will keep the end CR (blue) firmly locked in place so that you will cut a circular segment, and not an ellipse.

I use the back of an Xacto blade that has had the tip broken off to scrape a groove into the plastic. I make multiple, light passes, to deepen the cut until the tip can be removed. I don't use a saw, or the Xacto's cutting edge, as these can quickly allow a mistake to become magnified to the point where it will become easily visible.

After cutting the tip away, I clean up the edge with sandpaper. I also verify that the intended motor tube will fit inside the hole make sure that when a motor is installed that it won't bind before gluing the motor tube in place.

I use a similar method to groove the tips of nosecones (just not cutting as deep) for paint separation lines (simulated radomes, etc.)

Last edited: