You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Rule of Model Rocketey No. 641: You Need More Sandpaper than You Think You Need

- Thread starter brockrwood

- Start date

Help Support The Rocketry Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Using coarser sandpaper at first saves a ton of fine sandpaper.

The flexible type is nice to use instead of the normal stiff backing.

- Joined

- Jun 6, 2011

- Messages

- 7,563

- Reaction score

- 1,159

But then you have to use more of the finer grade to buff out the canyon walls. They screw you at the drive thru! BTW, the imitation sandpaper at the dollar stores use an inferior grade of adhesive and garnet 'spoils'. Okay for the home sheet rock one snd done projects and I do use it everyday on rough projects. Save yerself a little grief and 15 sheets of the cheep stuff and go with 3m or other. NOT starting glue thread!Using coarser sandpaper at first saves a ton of fine sandpaper.

What is this flexible stuff of which you speak? The kind that comes with the foam rubber backing?The flexible type is nice to use instead of the normal stiff backing.

- Joined

- Jun 6, 2011

- Messages

- 7,563

- Reaction score

- 1,159

+1 whut Steve sez! You wouldn't believe the chaps I've seen piling thru stacks or 800 when they need 60. Take notes, there WILL be a test.Using coarser sandpaper at first saves a ton of fine sandpaper.

@Steve Shannon+1 whut Steve sez! You wouldn't believe the chaps I've seen piling thru stacks or 800 when they need 60. Take notes, there WILL be a test.

I have to admit that my “go to” grits of sandpaper are:

180: Never use it. Should I?

220: Quickly reshape or grind down something, like a centering ring that is too big.

320: Use if I am scared to use 220 because 220 might sand too fast.

400: General purpose sanding, especially to get off heavy layer of wood filler. Also, Dry sanding (first pass) on the primer coat.

600: Finish sanding, to get smooth finish. Will use to wet sand the already dry sanded primer coat to a smooth surface for painting.

800: Never use it. Should I?

Buy some 80, 100, 120 and a scraper.@Steve Shannon

I have to admit that my “go to” grits of sandpaper are:

180: Never use it. Should I?

220: Quickly reshape or grind down something, like a centering ring that is too big.

320: Use if I am scared to use 220 because 220 might sand too fast.

400: General purpose sanding, especially to get off heavy layer of wood filler. Also, Dry sanding (first pass) on the primer coat.

600: Finish sanding, to get smooth finish. Will use to wet sand the already dry sanded primer coat to a smooth surface for painting.

800: Never use it. Should I?

When sanding, start with a coarse grade (use your judgment), sand until you’ve removed about half of the material you want to, then change to the next finer grit and sand until about half the sanding marks from the coarser grade are gone, then switch to one grade finer. Keep doing that, moving up a grade each time you’ve removed half the sanding marks from the previous grade until you get the finish you want.

For rockets I seldom go finer than 220. Primer and paint fills those marks. Of course my standards require it to look good from the flight line.

A sandpaper thread!! I tend to lean towards finer grits like 220, 320, 400. But when you need 80 you need 80. Don't be afraid to branch out. Flexible sandpaper is on my shopping list.

One bit of advice... Keep a wire brush nearby to periodically clean your paper (or file). Compressed air also works. Makes the world of difference.

One bit of advice... Keep a wire brush nearby to periodically clean your paper (or file). Compressed air also works. Makes the world of difference.

Last edited:

At least it is not a glue thread!A sandpaper thread!!

I have similar standards.my standards require it to look good from the flight line.

I know there are master modelers in this forum. I appreciate their gorgeous work. But I know my limitations. If it looks pretty good and flies well, I am happy.

In LPR I seldom find a need for anything coarser than 220. Certainly I would never touch balsa with coarser than 220, unless the objective is to convert the wood into sawdust as quickly as possible.

I use 220 for rough shaping, and initial removal of heavy primer or CWF layer. Then 400 for finish sanding. I also use 400 to shape the edges of balsa fins. Basswood can take 220.

I use 800 for smoothing the glued edges of my label-papered fins, because I've found it is the coarsest I can use that won't easily ruin the surface of the paper if I get careless.

I use 220 for rough shaping, and initial removal of heavy primer or CWF layer. Then 400 for finish sanding. I also use 400 to shape the edges of balsa fins. Basswood can take 220.

I use 800 for smoothing the glued edges of my label-papered fins, because I've found it is the coarsest I can use that won't easily ruin the surface of the paper if I get careless.

dr wogz

Fly caster

I will go down to 120 on a number of occasions. (but I've had lots of occasions!! experience speaks volumes!)

never really go over 400

There are different types of paper & grits. for wood, the reddish 'garnet paper is best, none of the fancier oxides or wet/dry.. at least not for wood.. they each have their place and their purpose.

A quality sanding bar, a quality sanding block, and a stiff piece of foam for contours & such.. don't just fold it over & use your hands / fingers..

And wear a mask!! Covid is over, use the masks you still have!!

never really go over 400

There are different types of paper & grits. for wood, the reddish 'garnet paper is best, none of the fancier oxides or wet/dry.. at least not for wood.. they each have their place and their purpose.

A quality sanding bar, a quality sanding block, and a stiff piece of foam for contours & such.. don't just fold it over & use your hands / fingers..

And wear a mask!! Covid is over, use the masks you still have!!

cloth backed sandpaper, very durable and long lasting,What is this flexible stuff of which you speak? The kind that comes with the foam rubber backing?

https://treelineusa.com/cloth-backe... sandpaper is incredibly," wide and 36" long.

I use this stuff - https://www.amazon.ca/gp/product/B074NJ24D6/ref=ppx_yo_dt_b_asin_title_o00_s00?ie=UTF8&psc=1What is this flexible stuff of which you speak? The kind that comes with the foam rubber backing?

You can get different grades but the super fine is a direct replacement for 400-600 grit sandpaper. It lasts a very long time, just wash it out once in a while. The sanding sponge is great for conformal surfaces and perfect for plastic nose cones to give it just enough texture for paint to adhere properly. I also use it on glassine to take the shine off.

For actual sandpaper I use 80 and 120 dry grits for coarser stuff then 180/220 wet-dry for medium then the above sanding sponge for wet-dry finishing. Plywood gets the coarse paper and if I am shaping leading/trailing edges I will use my mouse sander and 80 grit. Does the job in very short order.

Last edited:

I want in on the sand paper thread! lol I do buy alot of sand paper, but I never throw it away! My 100 grit is now 250ish. My 220 is now around 350... This is for balsa wood. Heavier woods will get newer (and hence more rough) sand paper.

lakeroadster

When in doubt... build hell-for-stout!

Oh fine...In LPR I seldom find a need for anything coarser than 220. Certainly, I would never touch balsa with coarser than 220, unless the objective is to convert the wood into sawdust as quickly as possible.

I use 220 for rough shaping, and initial removal of heavy primer or CWF layer. Then 400 for finish sanding. I also use 400 to shape the edges of balsa fins. Basswood can take 220.

I use 800 for smoothing the glued edges of my label-papered fins, because I've found it is the coarsest, I can use that won't easily ruin the surface of the paper if I get careless.

I just used 80 grit yesterday to fine tune the fit of the Cygnus Probe nose cone shoulder. It's made of pine.

Funkworks

Low Earth Orbit, obstructing Earth's view of Venus

- Joined

- Jul 28, 2018

- Messages

- 5,379

- Reaction score

- 6,053

lakeroadster

When in doubt... build hell-for-stout!

So... Marvin is ...Once in while, you can wash your sponges. Just soak and let dry. They'll be as good as new again!

View attachment 525881

I don't know if anyone else does this, but after trying it a few months ago, it seems to work for me.

- Joined

- Jan 17, 2009

- Messages

- 5,204

- Reaction score

- 1,547

I use a wide range, from 80 to 600. But have gone to 1000 or more in special cases.

Most-used are 120, 180, 240, 320, and 400.

If I'm rough-shaping a glider wing, I use 120, or coarser to get the rough shape. Then swap to finer grade like 240 for the final shape, and then fine grade like 400 for smoothing.

For a typical Estes kit balsa fin, with rounded edges, I'd start with 180 or 240, then jump to 400.

It's all dependent on the hardness of the material, how much wood needs to be removed, the final shape, and the desired finish.

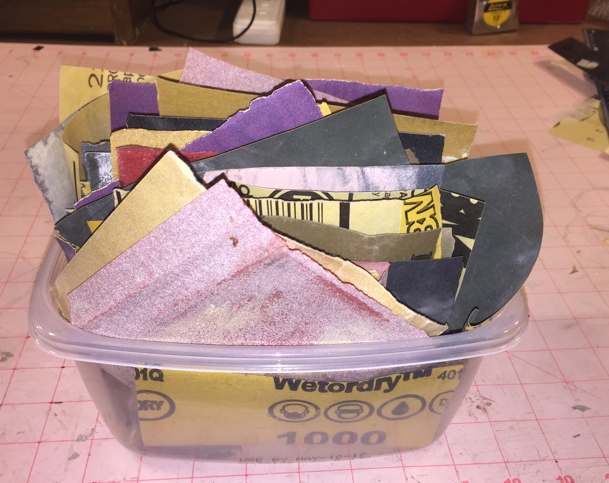

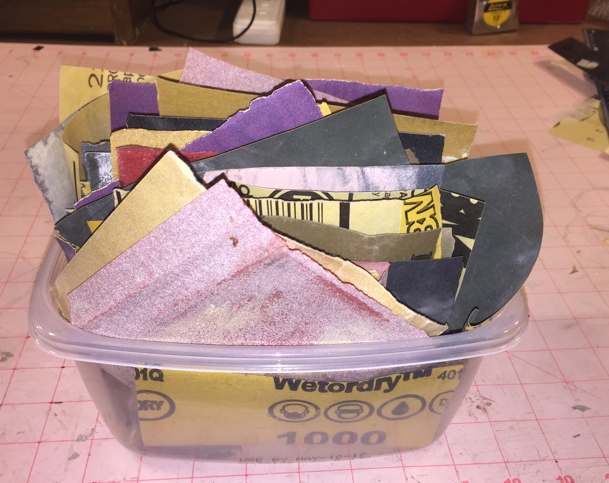

Here's a plastic tray holding sheets of used sandpaper, that I'll dig thru to find the grit I want. Unless I want to use a new sheet.

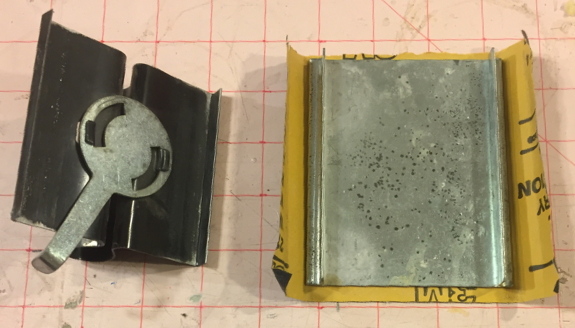

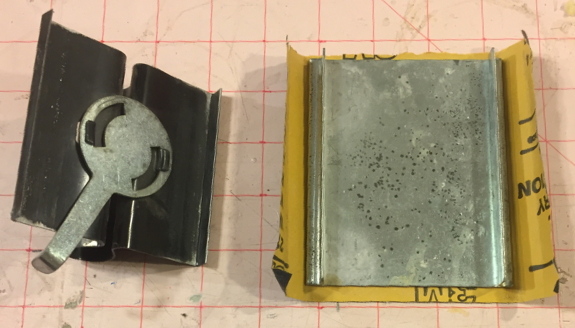

For sanding blocks to hold sandpaper, nothing beats this.

Red Devil , model #3319. I often found it in Ace Hardware type stores, but have not shopped for it in an Ace store in a long time. A google search in Ace Hardware does not find it.

Amazon has it. https://www.amazon.com/Red-Devil-3319-Sandpaper-Holder/dp/B00100OEZ6/ref=sr_1_2?crid=3QV17SJ655142

The paper easily clamps onto the block, which makes swapping the paper very easy. It uses a 4.5 x 5.5" sheet of sandpaper (so, it uses a 1/4 piece from a 9 x 11" sheet of sandpaper). I don't even cut the sheets, I just fold the sheets into quarters and tear along the fold.

The block has a rubber pad about 1/8" thick, but I do not like that. So, I remove the rubber pad so the block is flat and sturdy (The removed black rubber pad is seen in the upper right of the composite photo, showing it next to the flat base). That rubber pad is nice for say rounding corners on furniture, I do not like it for model work.

Now when I say this is my favorite sanding block, I do not mean favorite of several types. What I really mean is I have never used anything as good as this, so this is the only kind of sanding block I use..... unless I've misplaced one of them or forgot to bring one to a launch. Early in the hobby, I had 1" and 2" X-Acto blocks. They were almost useless to me, and the reason why I went looking for a better block.

I use this for sanding fins, wings, glider parts, helicopter (Rotaroc) blades, pretty much everything that a flat type of sanding block can be used for. Been using this kind of sanding block since the early 1970's.

Most-used are 120, 180, 240, 320, and 400.

If I'm rough-shaping a glider wing, I use 120, or coarser to get the rough shape. Then swap to finer grade like 240 for the final shape, and then fine grade like 400 for smoothing.

For a typical Estes kit balsa fin, with rounded edges, I'd start with 180 or 240, then jump to 400.

It's all dependent on the hardness of the material, how much wood needs to be removed, the final shape, and the desired finish.

Here's a plastic tray holding sheets of used sandpaper, that I'll dig thru to find the grit I want. Unless I want to use a new sheet.

For sanding blocks to hold sandpaper, nothing beats this.

Red Devil , model #3319. I often found it in Ace Hardware type stores, but have not shopped for it in an Ace store in a long time. A google search in Ace Hardware does not find it.

Amazon has it. https://www.amazon.com/Red-Devil-3319-Sandpaper-Holder/dp/B00100OEZ6/ref=sr_1_2?crid=3QV17SJ655142

The paper easily clamps onto the block, which makes swapping the paper very easy. It uses a 4.5 x 5.5" sheet of sandpaper (so, it uses a 1/4 piece from a 9 x 11" sheet of sandpaper). I don't even cut the sheets, I just fold the sheets into quarters and tear along the fold.

The block has a rubber pad about 1/8" thick, but I do not like that. So, I remove the rubber pad so the block is flat and sturdy (The removed black rubber pad is seen in the upper right of the composite photo, showing it next to the flat base). That rubber pad is nice for say rounding corners on furniture, I do not like it for model work.

Now when I say this is my favorite sanding block, I do not mean favorite of several types. What I really mean is I have never used anything as good as this, so this is the only kind of sanding block I use..... unless I've misplaced one of them or forgot to bring one to a launch. Early in the hobby, I had 1" and 2" X-Acto blocks. They were almost useless to me, and the reason why I went looking for a better block.

I use this for sanding fins, wings, glider parts, helicopter (Rotaroc) blades, pretty much everything that a flat type of sanding block can be used for. Been using this kind of sanding block since the early 1970's.

Last edited:

Funkworks

Low Earth Orbit, obstructing Earth's view of Venus

- Joined

- Jul 28, 2018

- Messages

- 5,379

- Reaction score

- 6,053

lakeroadster

When in doubt... build hell-for-stout!

dr wogz

Fly caster

if you can find it / them:

the great planes SAnding bar is / was one of the best out there!

https://www.hobbytown.com/great-planes-5.5-easytouch-hand-sander-gpmr6169/p233919

the great planes SAnding bar is / was one of the best out there!

https://www.hobbytown.com/great-planes-5.5-easytouch-hand-sander-gpmr6169/p233919

Similar threads

- Replies

- 6

- Views

- 352

- Replies

- 63

- Views

- 1K

- Replies

- 3

- Views

- 252