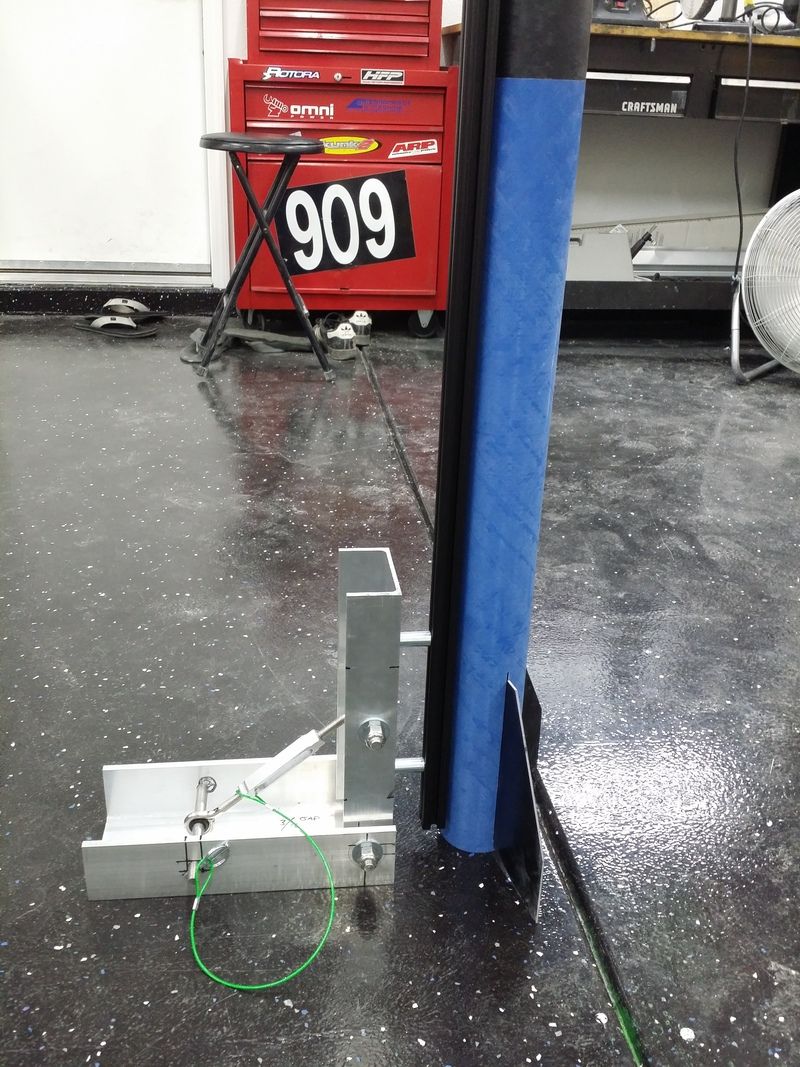

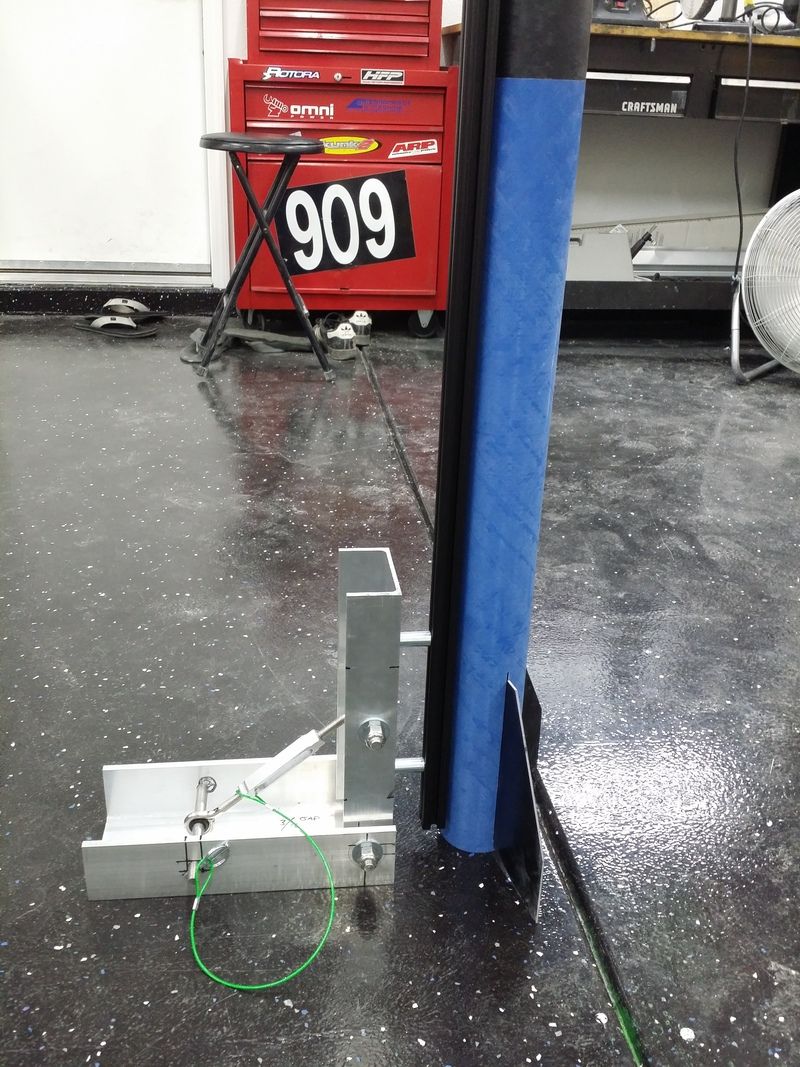

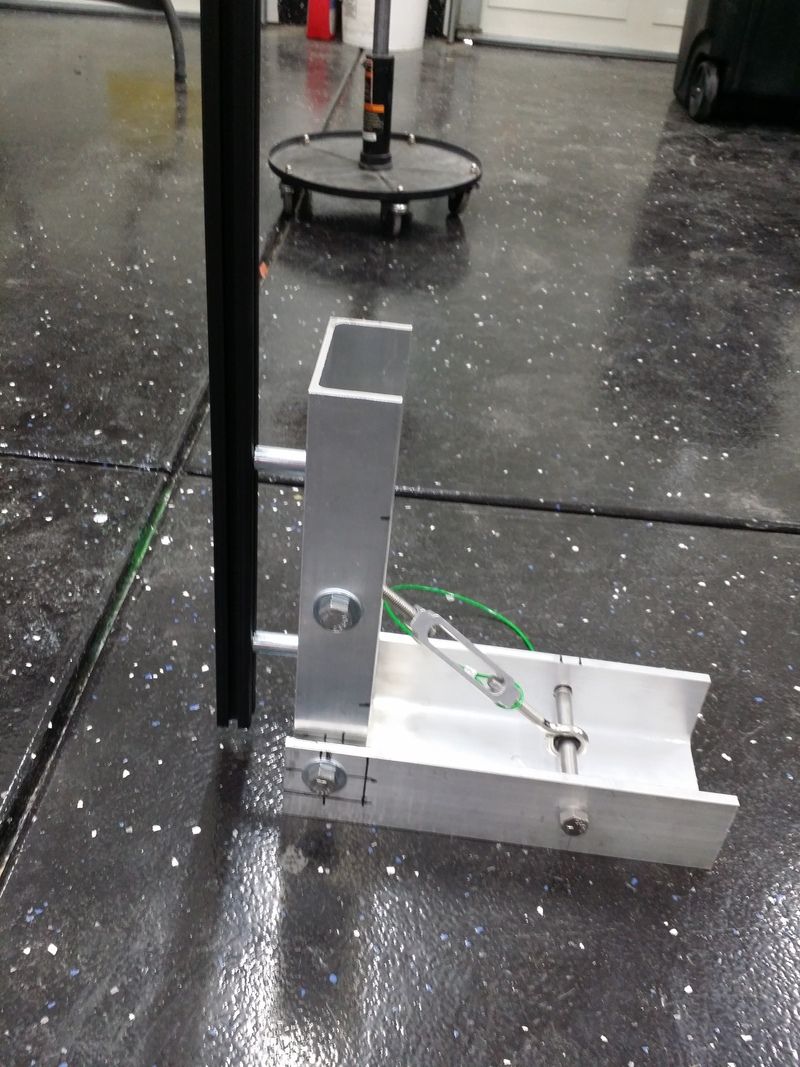

In the never ending quest to research the best methods, learn from others or get new ideas....for the last 3 months I have been searching for a rail launcher for purchase or something I can build. I spent a lot of time going back and forth from a Jaw stand or welding custom parts, to buying one, back to the jaw stand, welding, cutting and grinding, drawing 4 different designs....untill a neat setup showed up. It either popped up here in a search or a google image search. So if you are the original designer, thank you. Thank you very much!

I ordered most of the parts a while ago, specifically the angle aluminum channel, and the side exit elbow, made 2 trips to our local McFaddendale's (mcmastercarr) and about spent 3 weeks drawing to scale different ideas or ways to use parts etc..

While building a launch pad is not rocket science, I did want some thing that would meet the following requirements that made sense in my head and on paper;

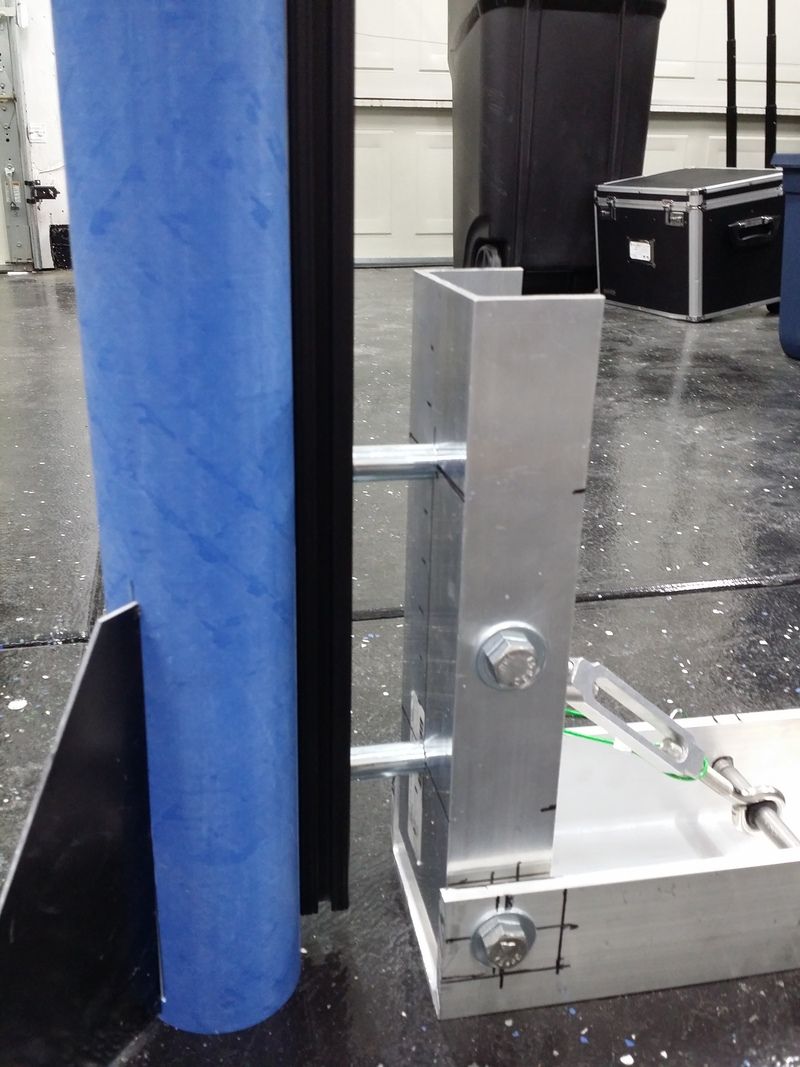

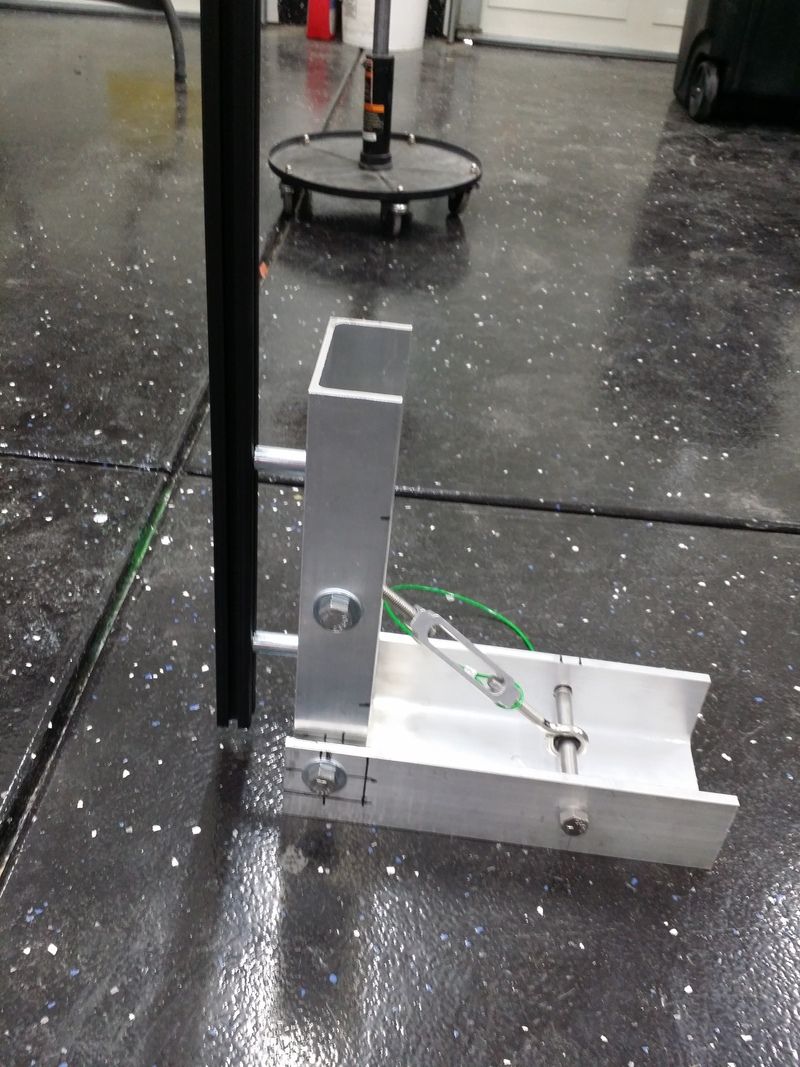

Rigid

Portable, break down

Less than 16 pounds

Expandable to bigger rails and rockets

Strong

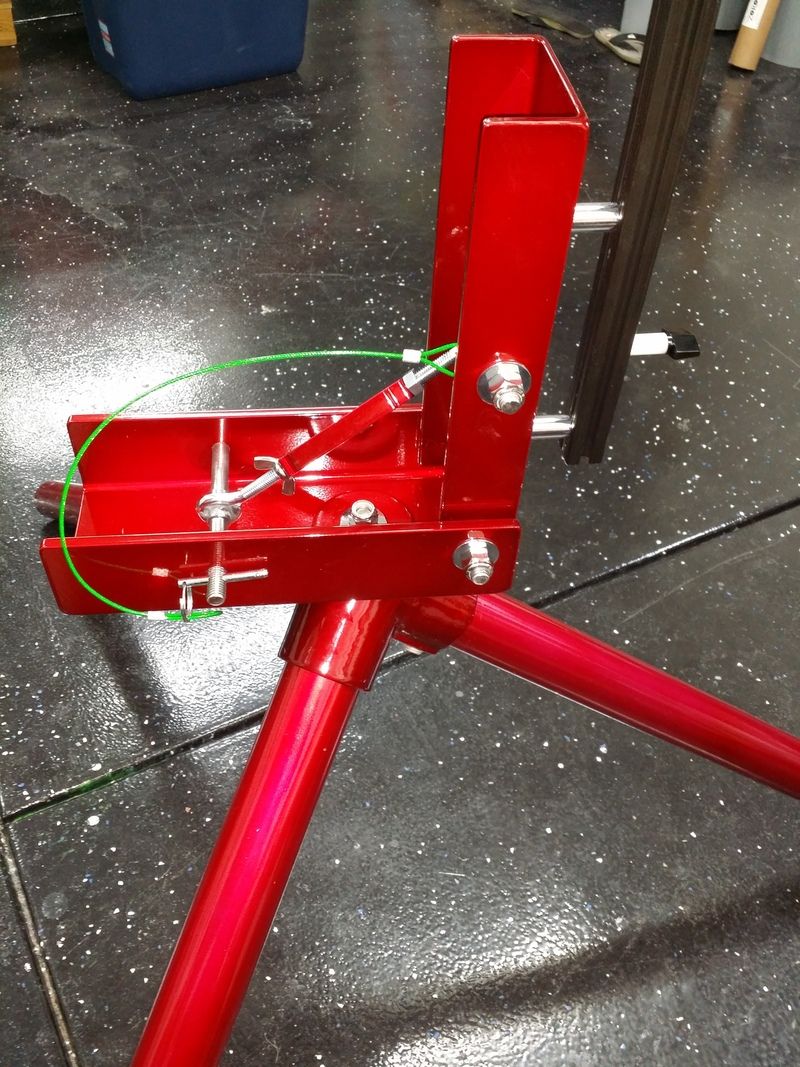

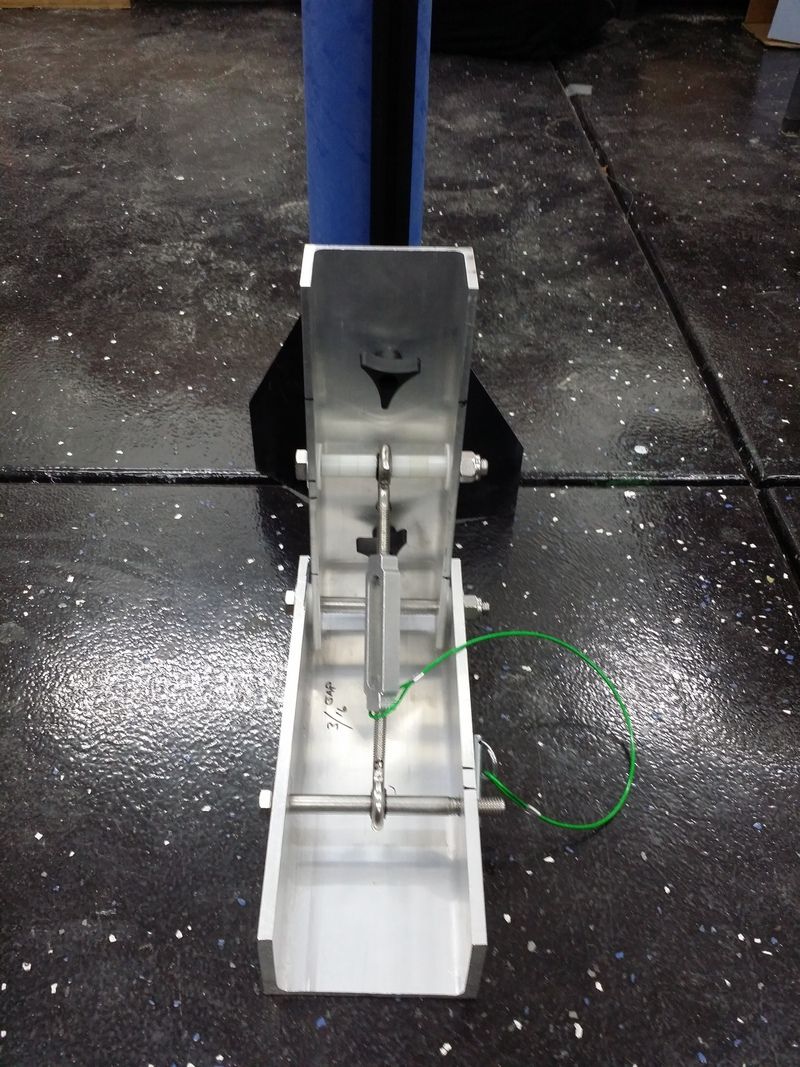

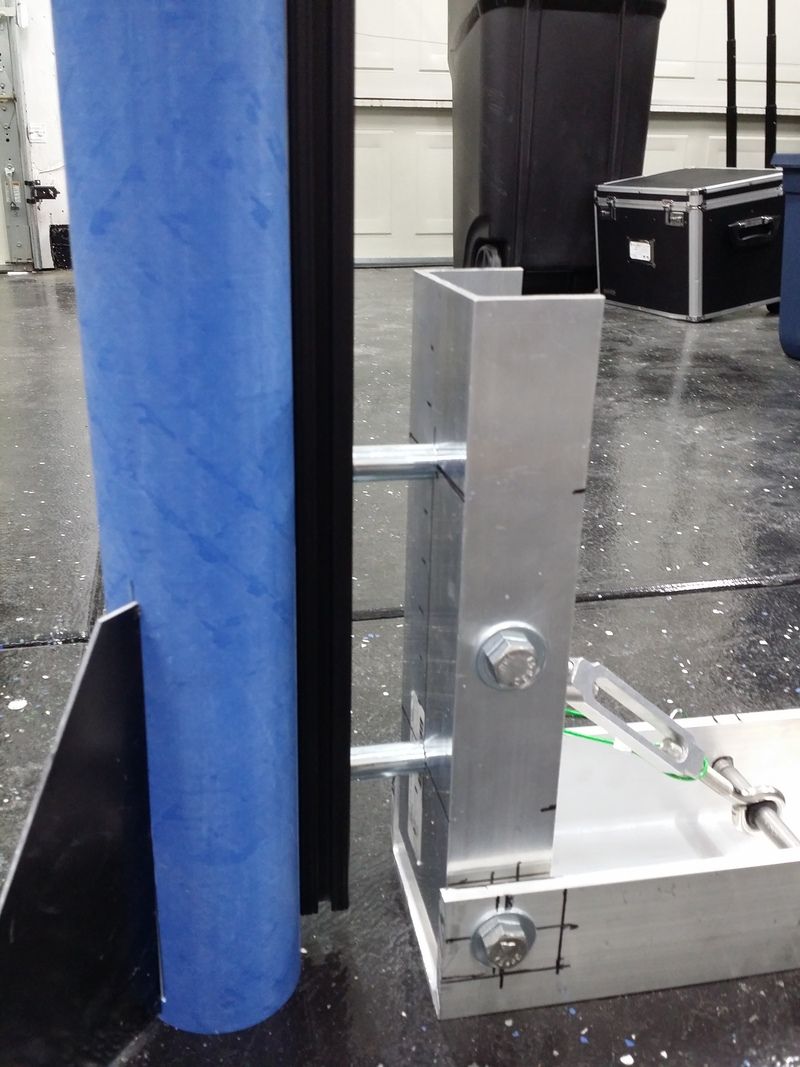

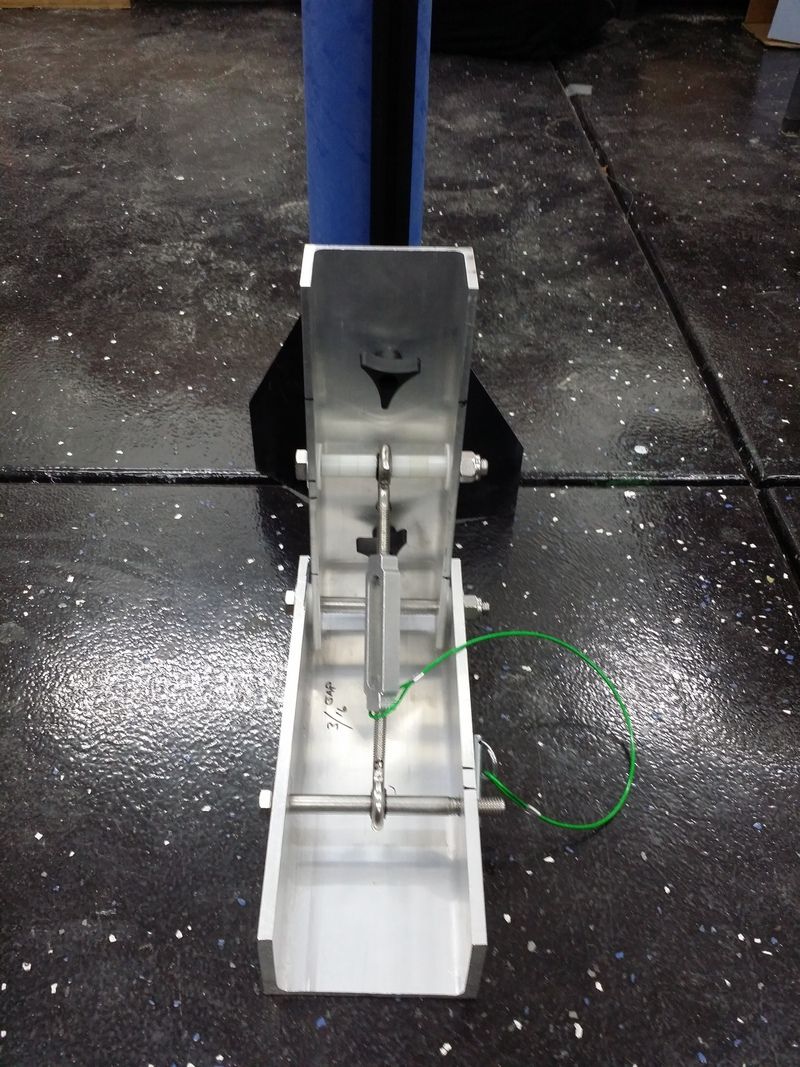

Adjustable launch angle and direction

Adjustable Blast plate and stop bolt

No welding required

Heavy duty

Able to be staked down

Metal

Durable

Safe

Easy to duplicate, inventory parts, parts suppliers and exact prices.

Less than 160$

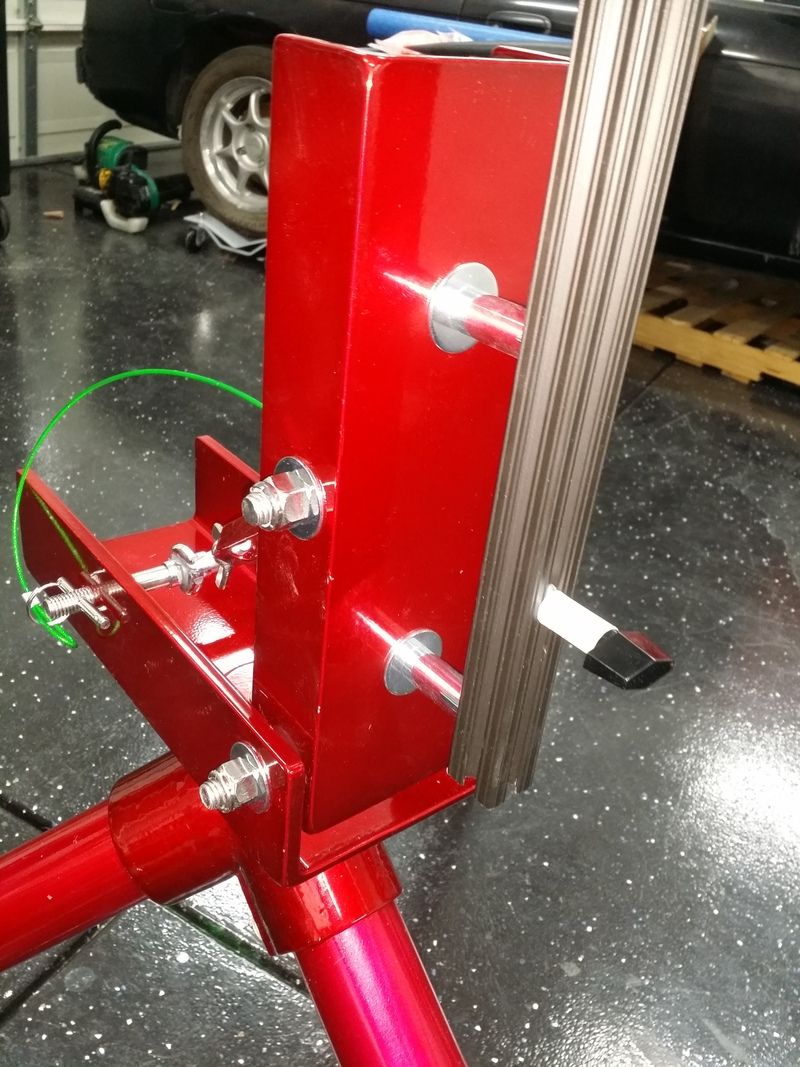

After a few hours back and forth from the drill press to the table measuring.....here we are at the rough stage of assembly. Still more to go and a few more things to do.

I would like to hear your guys' thoughts or ideas, thanks!

I ordered most of the parts a while ago, specifically the angle aluminum channel, and the side exit elbow, made 2 trips to our local McFaddendale's (mcmastercarr) and about spent 3 weeks drawing to scale different ideas or ways to use parts etc..

While building a launch pad is not rocket science, I did want some thing that would meet the following requirements that made sense in my head and on paper;

Rigid

Portable, break down

Less than 16 pounds

Expandable to bigger rails and rockets

Strong

Adjustable launch angle and direction

Adjustable Blast plate and stop bolt

No welding required

Heavy duty

Able to be staked down

Metal

Durable

Safe

Easy to duplicate, inventory parts, parts suppliers and exact prices.

Less than 160$

After a few hours back and forth from the drill press to the table measuring.....here we are at the rough stage of assembly. Still more to go and a few more things to do.

I would like to hear your guys' thoughts or ideas, thanks!

Last edited: