Here is a neat little tech tip for composite makers that use peel plys to achieve that secondary bonding or for that smooth finish. Just like fiberglass and carbon fabrics, peel ply also frays strands (except for porous teflon peel ply). This is an annoying issue especially when making tubes. After the glue has hardened and pulling the peel ply at the end where it was cut, small strands will get embedded in the tube. These can be annoying to remove.

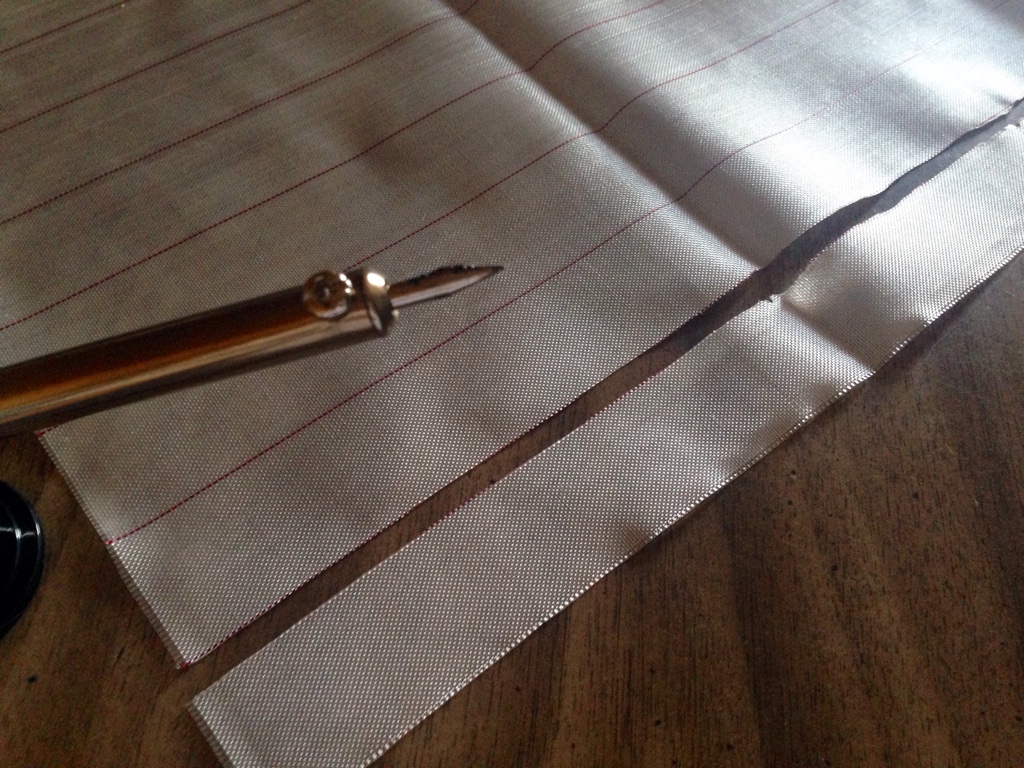

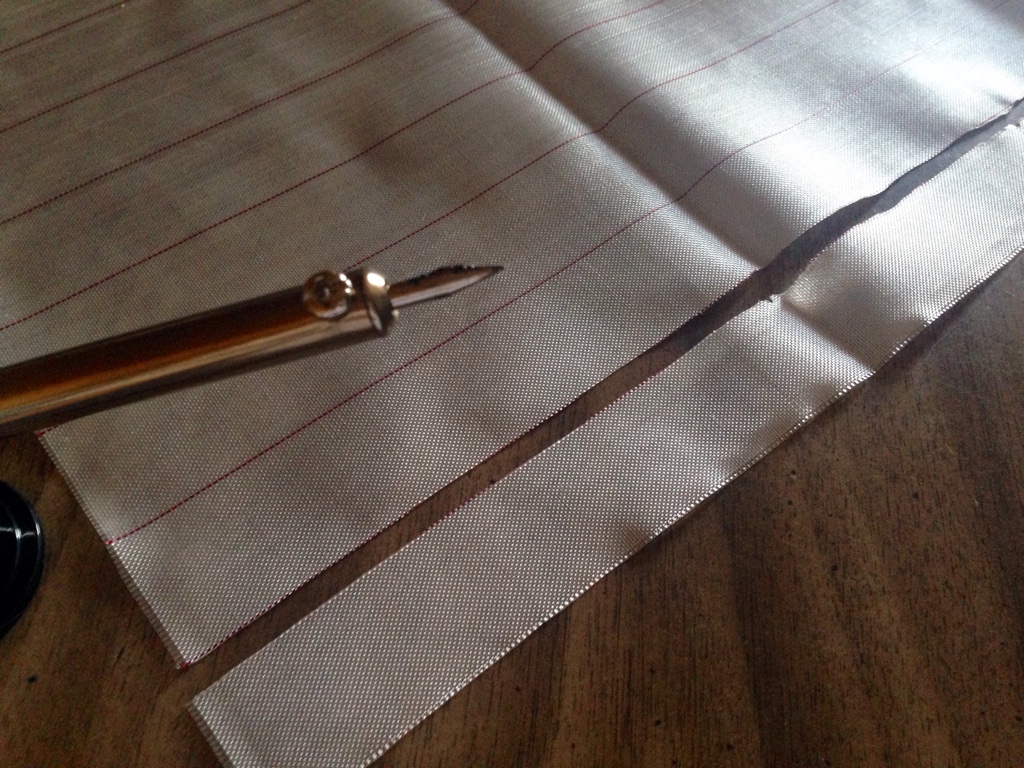

I read somewhere that peel ply can be hot knife slit, so after much thinking I thought, why not try a soldering iron. I bought me a 30 Watt soldring iron that heats up to 735F. I let it heat up to its max temp and it cut the peel ply really well.

The results is a hot melted cut edge that prevents the fabric from fraying. Hope this helps out for you composite makers.

Alexander Solis - TRA Level 1 - Mariah 54 - CTI-I100 Red Lightning Longburn - 6,345 Feet

I read somewhere that peel ply can be hot knife slit, so after much thinking I thought, why not try a soldering iron. I bought me a 30 Watt soldring iron that heats up to 735F. I let it heat up to its max temp and it cut the peel ply really well.

The results is a hot melted cut edge that prevents the fabric from fraying. Hope this helps out for you composite makers.

Alexander Solis - TRA Level 1 - Mariah 54 - CTI-I100 Red Lightning Longburn - 6,345 Feet