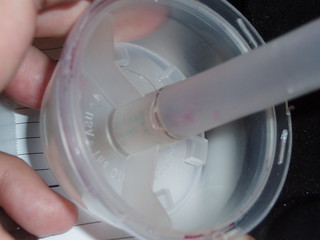

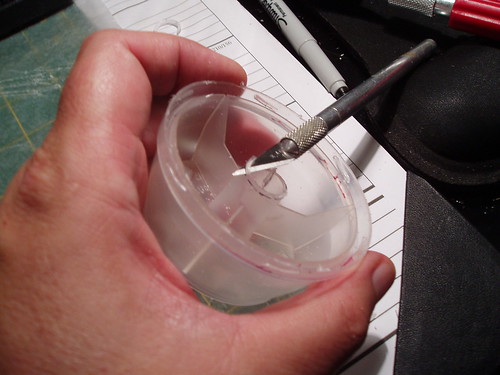

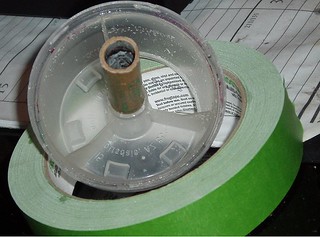

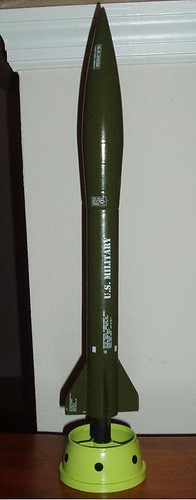

In the grand tradition of PGC as demonstrated by MrGneissGuy and GDJ, I have just finished this build of the Midge (a small, annoying flying object). The build starts off with this:

Last edited:

Following this for sure... Have a dried up one of these sitting in the other room.

op:

op::cool2:

I think may you should prolong this thread as much as possible. jus sayin!

<giggle>. If this were a complex build that had multiple exacting steps like an accurate scale model or an L3 build, I could see making it lengthier. But this is a really simple build and the length of the build thread will be commensurate

Who'd thunked a rocket from an air freshener container?

Gary....so what you mean is we can actually see the launch in our lifetime? LOL

Got more popcorn poppin fer ya.

I can't figure his direction, this will be fun. Who'd thunked a rocket from an air freshener container?

Very clever idea! Sure wish I could have seen the launch!

Thanks QQ! I had hopes this thread would inspire more PGC

Enter your email address to join: