patelldp

Well-Known Member

- Joined

- Jan 23, 2009

- Messages

- 5,647

- Reaction score

- 101

The Mach Buster is set to make its return! This 1.125" diameter kit accepts 24mm motors and features state-of-the-art 3D printed components. These kits will take whatever motor you can fit, just don't blink when it lights!

Kit Specs

Length - 14.25"

Diameter - 1.125"

Weight - 4oz (with epoxy, paint, and streamer)

Motor Recommendations

What's in the bag:

Price is $30 plus $5 shipping to the US. I currently have six bagged and ready to go with many more to follow. These will be TRF exclusive for the time being! PM me with interest!

Kit Specs

Length - 14.25"

Diameter - 1.125"

Weight - 4oz (with epoxy, paint, and streamer)

Motor Recommendations

- Estes: C6-5 (requires adapter), C11-7, D12-7, E9-8, E12-8

- Aerotech: E18-7W, E20-8W, F35-11W, F39-9-T, F32-8T, F44-8W, G55-10W (if you can find one!)

- Cesaroni Pro24: 1-3G motors (6G fit but leave very little room for recovery)

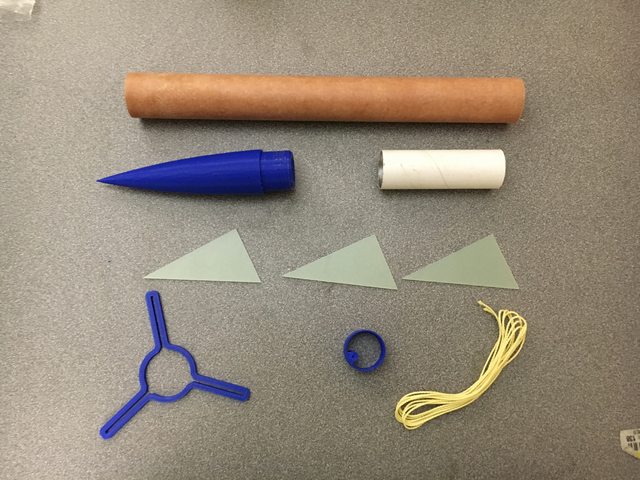

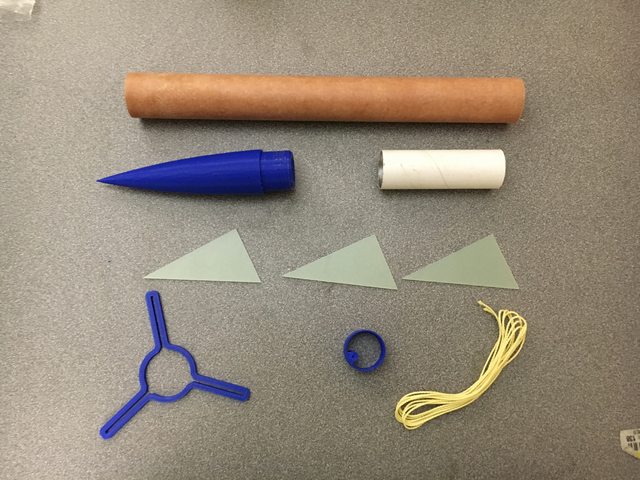

What's in the bag:

- XX Phenolic Body tube with 24mm Motor tube

- 3D Printed Nosecone with integrated shock cord mount

- 1/16" G10 fins, precision CNC cut

- 6 ft. 250# braided Kevlar shock cord with 3-D printed anchor

- 3D Printed fin alignment guide

Price is $30 plus $5 shipping to the US. I currently have six bagged and ready to go with many more to follow. These will be TRF exclusive for the time being! PM me with interest!