CoachSteve

Well-Known Member

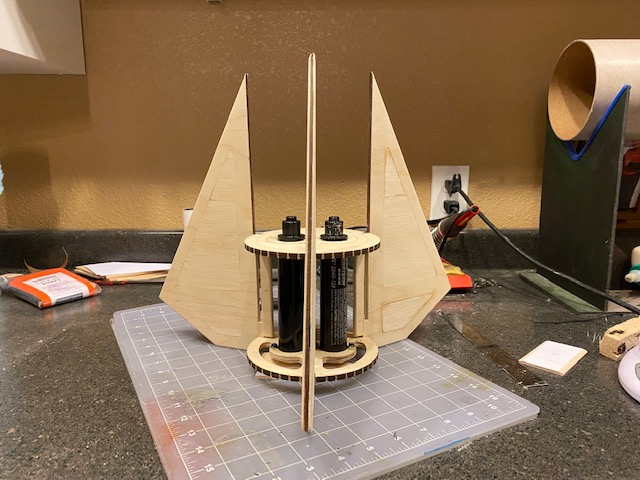

So, I wanted to try to build a Magg that would comply with level zero regulations.

1500G or less total weight

125g or less of propellant

Average thrust per motor less than 80N

Total thrust less than 320N

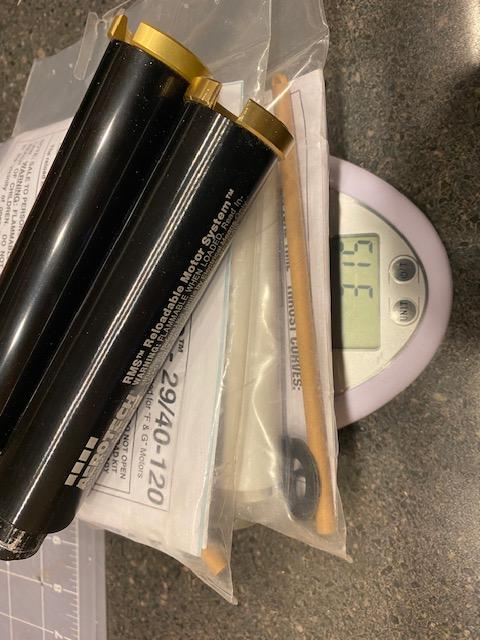

The plan is a twin 29mm Magg sporting 2 G53FJs.

G53 has 60 grams of propellant and 53N of average thrust

so -

3.3lb rocket

120 grams of propellant (in 2 separate motors)

106N average thrust (in 2 separate motors)

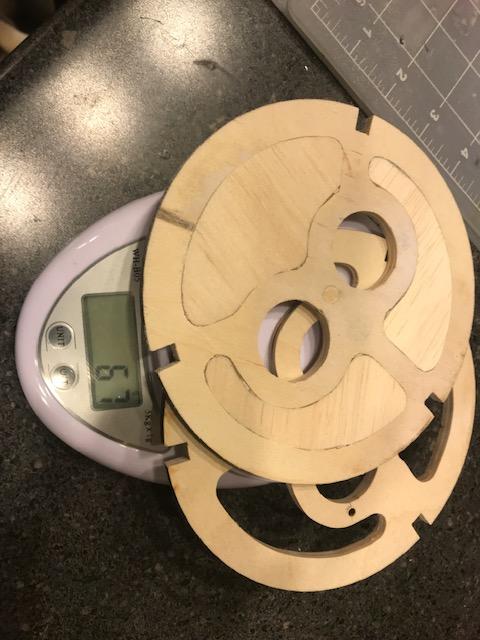

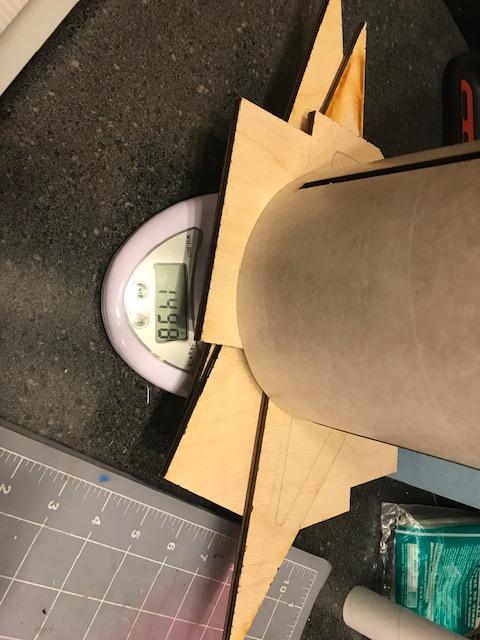

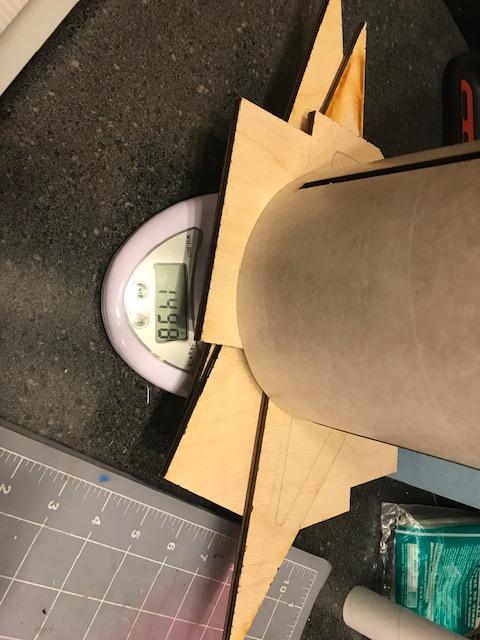

So to kick this off I needed to see what I was starting with. kit out of the bag, with all hardware, less glue and paint comes in at 1498G

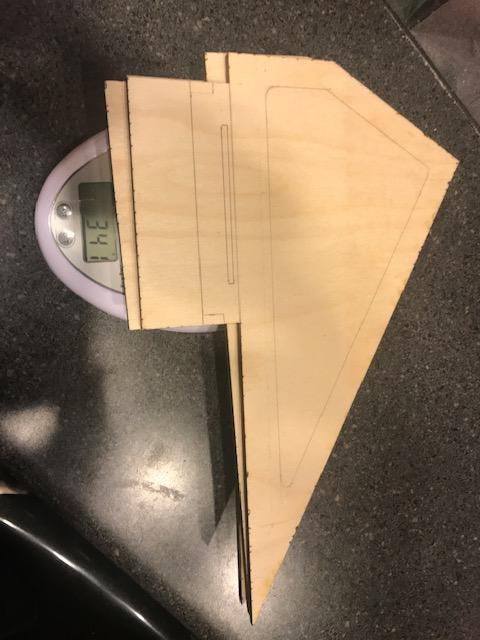

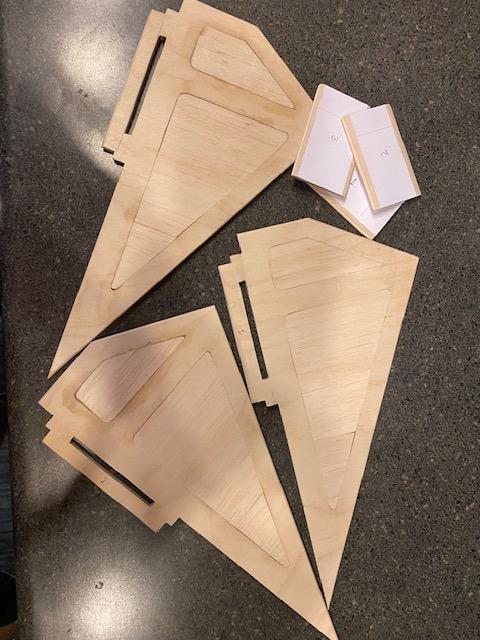

Time to start shaving weight.

1500G or less total weight

125g or less of propellant

Average thrust per motor less than 80N

Total thrust less than 320N

The plan is a twin 29mm Magg sporting 2 G53FJs.

G53 has 60 grams of propellant and 53N of average thrust

so -

3.3lb rocket

120 grams of propellant (in 2 separate motors)

106N average thrust (in 2 separate motors)

So to kick this off I needed to see what I was starting with. kit out of the bag, with all hardware, less glue and paint comes in at 1498G

Time to start shaving weight.