billdz

Well-Known Member

- Joined

- Feb 10, 2017

- Messages

- 1,377

- Reaction score

- 121

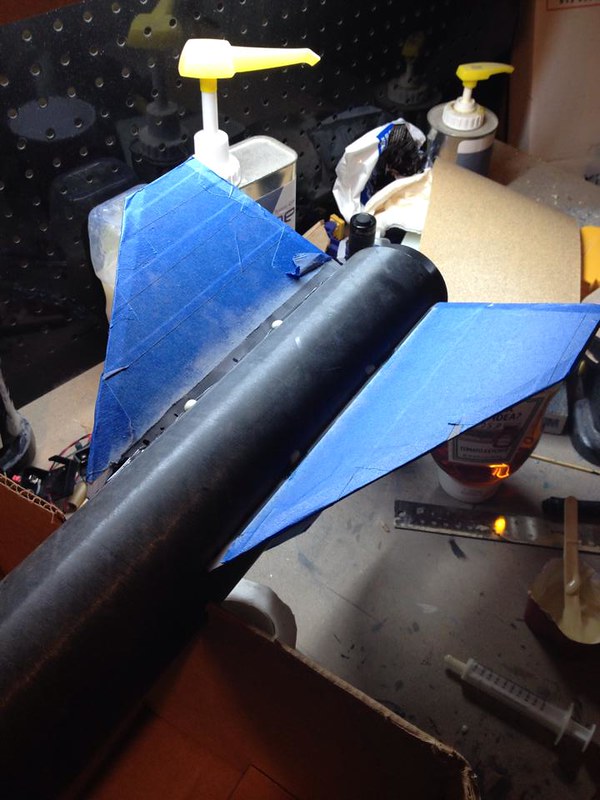

Working on the internal fillers for my Painkiller Max. The airframe is 4.5" and the MM is 3". I mounted the MM without the rear CR and planned to make the internal fillets by sticking a spoon tied to a rod up from the bottom of the airframe. I'm using Rocket Poxy, which seems thicker than epoxy I've previously used. I can't seem to get this epoxy to go where it is supposed to go. It does not flow at all. Most of the epoxy I send up on the spoon ends up on a fin or on the MM, everywhere except to the junction of the fin and MM. The Rocket Poxy instructions say the mixture can be thinned with alcohol, but thinning does not seem to fix the problem. Is there a different type of epoxy, something that easily "runs" downhill to the junction? Or is there a better way to make the internal fillets? Someone suggested blowing the epoxy into the junction with an aquarium hose.