***SPOILER ALERT!!!***

(NOTE: I'm behind on writing and updating the build thread since I was rushing to finish the rocket for the club's last launch. If you don't like spoilers, please ignore the totally awesome posts here and skip to post #71.) :grin:

Hey Guys!

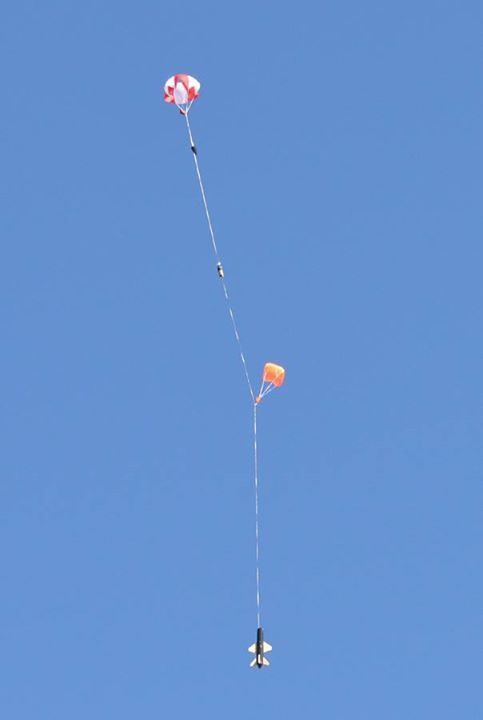

Guess what I did with the X-15 today? L2 Yo! :grin:

I'll update this build thread over the course of this week since I'm exhausted right now, but great news is that my custom DD mod was (as the announcer put it) "perfectly executed" and I've certified L2 with the X-15 in this thread. :w:

Here's a video of the maiden (sorry for the poor video quality...I had lots going on and didn't have a chance to grab another camera):

https://www.youtube.com/watch?v=ZRnYykwEKyw&feature=youtu.be

[video=youtube;ZRnYykwEKyw]https://www.youtube.com/watch?v=ZRnYykwEKyw&feature=youtu.be[/video]

(NOTE: I'm behind on writing and updating the build thread since I was rushing to finish the rocket for the club's last launch. If you don't like spoilers, please ignore the totally awesome posts here and skip to post #71.) :grin:

Hey Guys!

Guess what I did with the X-15 today? L2 Yo! :grin:

I'll update this build thread over the course of this week since I'm exhausted right now, but great news is that my custom DD mod was (as the announcer put it) "perfectly executed" and I've certified L2 with the X-15 in this thread. :w:

Here's a video of the maiden (sorry for the poor video quality...I had lots going on and didn't have a chance to grab another camera):

https://www.youtube.com/watch?v=ZRnYykwEKyw&feature=youtu.be

[video=youtube;ZRnYykwEKyw]https://www.youtube.com/watch?v=ZRnYykwEKyw&feature=youtu.be[/video]

Last edited: