Sparkytfl

Well-Known Member

- Joined

- May 11, 2012

- Messages

- 236

- Reaction score

- 0

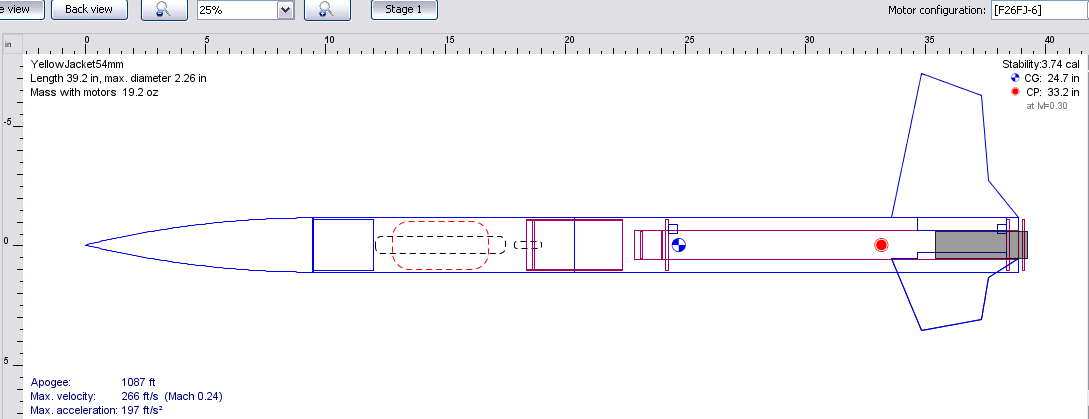

I've got a pile of parts in the mail, about to start a build. I've done fifteen or twenty estes kits, but this will be my first scratch build, and my first one to use anything bigger than a C6. Just want to make sure nobody sees any fatal flaws to my design that might be obvious to anyone else. Then I'll be starting right away when my parts arrive on friday.

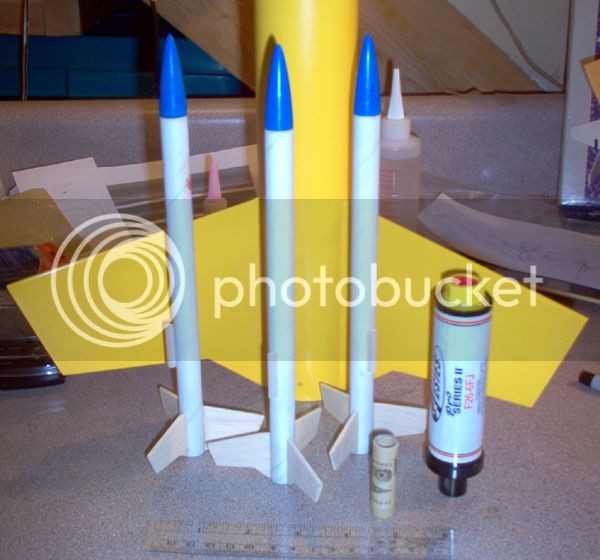

This will be an upscale of what I think is one of the most attractive kits from my first time around in the mid nineties. The Yellow Jacket.

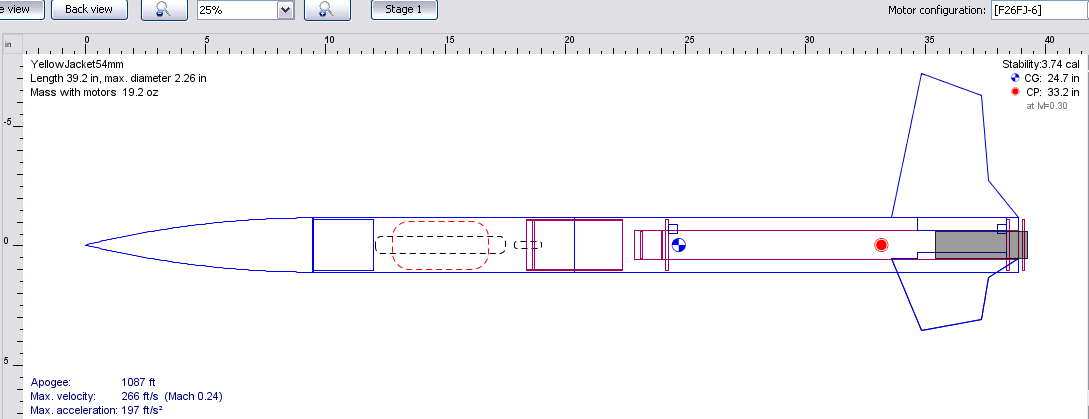

Here's the basic plan.

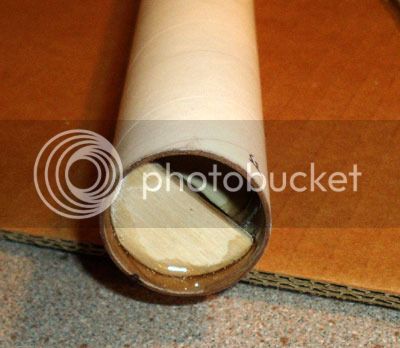

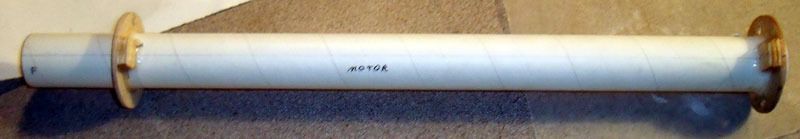

It will be 54mm loc tube, 29mm motor, about 39inches and about 16ounces empty. Plywood fins, through-the-wall. It will be center break zipperless with baffles in the end of the motor tube as inspired by all of qquake2k's awesome build threads. Nylon chute 24 inch, not sure about shock cord yet. It will use rail buttons since the local club requires rails for larger than E. They'll be screwed into blocks glued to the centering rings.

I have a few questions about the center break design. The location of the break is being determined mostly by the look of the original, with the break right where the black half meets the stripes. This leaves me about six inches of tube to fit the chute and shock cord. Will that be enough to fit a 24inch nylon? I've never used nylon and dont know how small it folds. I might have to move the break to below the stripes.

I'm not entirely sure on how to determine the length of the inner tube. I know making it longer and the ring forward will help the ejection pressure, but will moving it too far forward blast the cone off with too much force? The current design has it as long as it is so that the front centering ring (along with the rail button) will be around CG. I do have room to make it extend a few inches into the coupler. By the way, is there a standard coupler length in these center breaks? I'm figuring about 4.5inches so it sticks 1 diameter into each tube.

How many of those half-moon bafles should it have, and is there a trick to how far apart to space them?

How's the CG and CP look, is that good or will the little bit of overstability give problems with it flying into the wind like my Bertha?

I havent bought plywood yet, is 1/8 going to be good, or should I go 3/16? Typical engine will be an F, but I'd like it to survive on a bigger G if I feel like launching it to 2000ft. It probably wont be used for lv1 since I dont trust it returning from 4000 on single deploy. I'm planning on epoxy for structural bits and wood glue for fillets. Five minute epoxy like from the hardware store, is that what everyone uses?

I'll also be building a swarm of bt5 downscales, plus my estes hornet. Ironically, I'm terrified of bees.

This will be an upscale of what I think is one of the most attractive kits from my first time around in the mid nineties. The Yellow Jacket.

Here's the basic plan.

It will be 54mm loc tube, 29mm motor, about 39inches and about 16ounces empty. Plywood fins, through-the-wall. It will be center break zipperless with baffles in the end of the motor tube as inspired by all of qquake2k's awesome build threads. Nylon chute 24 inch, not sure about shock cord yet. It will use rail buttons since the local club requires rails for larger than E. They'll be screwed into blocks glued to the centering rings.

I have a few questions about the center break design. The location of the break is being determined mostly by the look of the original, with the break right where the black half meets the stripes. This leaves me about six inches of tube to fit the chute and shock cord. Will that be enough to fit a 24inch nylon? I've never used nylon and dont know how small it folds. I might have to move the break to below the stripes.

I'm not entirely sure on how to determine the length of the inner tube. I know making it longer and the ring forward will help the ejection pressure, but will moving it too far forward blast the cone off with too much force? The current design has it as long as it is so that the front centering ring (along with the rail button) will be around CG. I do have room to make it extend a few inches into the coupler. By the way, is there a standard coupler length in these center breaks? I'm figuring about 4.5inches so it sticks 1 diameter into each tube.

How many of those half-moon bafles should it have, and is there a trick to how far apart to space them?

How's the CG and CP look, is that good or will the little bit of overstability give problems with it flying into the wind like my Bertha?

I havent bought plywood yet, is 1/8 going to be good, or should I go 3/16? Typical engine will be an F, but I'd like it to survive on a bigger G if I feel like launching it to 2000ft. It probably wont be used for lv1 since I dont trust it returning from 4000 on single deploy. I'm planning on epoxy for structural bits and wood glue for fillets. Five minute epoxy like from the hardware store, is that what everyone uses?

I'll also be building a swarm of bt5 downscales, plus my estes hornet. Ironically, I'm terrified of bees.