Cameron Anderson

Well-Known Member

Just curious what the limits are for commercial FG nosecones in terms of speed.

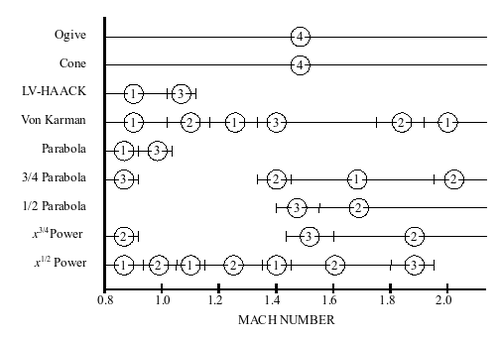

Does diameter make a difference? Are 3" stronger than 4"? Does brand matter? Are RW/CW better or worse than Wildman? Are VK stronger than standard ogive?

Does diameter make a difference? Are 3" stronger than 4"? Does brand matter? Are RW/CW better or worse than Wildman? Are VK stronger than standard ogive?