You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Estes T25 Centurian REBUILD

- Thread starter Crawf56

- Start date

Help Support The Rocketry Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Crawf56

Pig Soooiiieee!!

The T25 is Estes kit # 2200. Here is a link to the instructions:

https://www.estesrockets.com/customer-service/instructions/#002000

The T25 was a noble effort by Estes, to get an RC rocket glider available. But it was a challenge to fly, and the Elevator control cable tended to get stuck.

I tended to fly my model at RC airplane "fun flys", and it was always a crowd pleaser. The pile of parts you see now occurred when I tried to do seven things at once, and incorrectly loaded a boost motor with my D11-P. The E9-P motor worked best, but I had discovered that I could put a D12-0 boost motor in front of a D11-P. (The motor must NOT have an ejection charge.)

Having seen various flying wing aircraft, my plan is to eliminate the Elevator control, and fly the model by Ailerons only. I have done dumber things........:eyeroll:

https://www.estesrockets.com/customer-service/instructions/#002000

The T25 was a noble effort by Estes, to get an RC rocket glider available. But it was a challenge to fly, and the Elevator control cable tended to get stuck.

I tended to fly my model at RC airplane "fun flys", and it was always a crowd pleaser. The pile of parts you see now occurred when I tried to do seven things at once, and incorrectly loaded a boost motor with my D11-P. The E9-P motor worked best, but I had discovered that I could put a D12-0 boost motor in front of a D11-P. (The motor must NOT have an ejection charge.)

Having seen various flying wing aircraft, my plan is to eliminate the Elevator control, and fly the model by Ailerons only. I have done dumber things........:eyeroll:

Crawf56

Pig Soooiiieee!!

So, here we go.

First step is to get the Lower Fuselage attached again. This is a bit of a problem, because I am trying to attach plastic (the Fuselage) to wood (the Wing):

My plan is to add some balsa blocks to give a surface to glue the Lower Fuselage to. I hope to use epoxy and hot glue 'strategically'.

First step is to get the Lower Fuselage attached again. This is a bit of a problem, because I am trying to attach plastic (the Fuselage) to wood (the Wing):

My plan is to add some balsa blocks to give a surface to glue the Lower Fuselage to. I hope to use epoxy and hot glue 'strategically'.

Crawf56

Pig Soooiiieee!!

Epoxyed some balsa "blocks" to help hold the fuselage:

Decided to use hot glue to attach the fuselage (or 'nose cone'). Hot glue does not dry hard like epoxy, leaving a 'rubbery' feel. But you have to act fast, because hot glue sets within 30 seconds. Hopefully the toughness of the hot glue will help keep the fuselage in place on lift-off and landings.

Not pretty, but hopefully effective:

Decided to use hot glue to attach the fuselage (or 'nose cone'). Hot glue does not dry hard like epoxy, leaving a 'rubbery' feel. But you have to act fast, because hot glue sets within 30 seconds. Hopefully the toughness of the hot glue will help keep the fuselage in place on lift-off and landings.

Not pretty, but hopefully effective:

Crawf56

Pig Soooiiieee!!

Re-attaching the left fin and boom.

I put wax paper on my flat workbench, attached the broken parts with 30-minute epoxy, and folded the wax paper over the top of the glue area. On top of that, I put a plastic bag filled with shot, which I use as a 'hold-in-place' weight.

The green thing is the horizontal stabilizer (elevator removed), which is still attached to the left fin (rudder).

I put wax paper on my flat workbench, attached the broken parts with 30-minute epoxy, and folded the wax paper over the top of the glue area. On top of that, I put a plastic bag filled with shot, which I use as a 'hold-in-place' weight.

The green thing is the horizontal stabilizer (elevator removed), which is still attached to the left fin (rudder).

Crawf56

Pig Soooiiieee!!

So, I have to put the twin booms back on:

So, I got out these four pieces of foam that are the same height, and I was going to get everything set up, then take this really cool pic. :eyeroll:

At which point I discovered that the booms are not parallel to the bottom of the wing. Decided to do one boom at a time, seeing that a little "up" elevator was built into the design. (Having flown the model, I know the "up" is needed.)

So, I got out these four pieces of foam that are the same height, and I was going to get everything set up, then take this really cool pic. :eyeroll:

At which point I discovered that the booms are not parallel to the bottom of the wing. Decided to do one boom at a time, seeing that a little "up" elevator was built into the design. (Having flown the model, I know the "up" is needed.)

- Joined

- Jan 17, 2009

- Messages

- 5,204

- Reaction score

- 1,547

Man, I do not see how you expect to make it fly without any R/C elevator control, using aileron control. And also considering that unless dead-perfect trimmed to NOT pitch up or down during boost, it needs some elevator correction. Especially since this is a no moving parts rocket glider as opposed to a boost glider with a pop-pod to make it nose-heavy on boost. Also if the boost trim happened to be dead perfect not to pitch on boost, it would then fly ballistically like an arrow.......not glide.

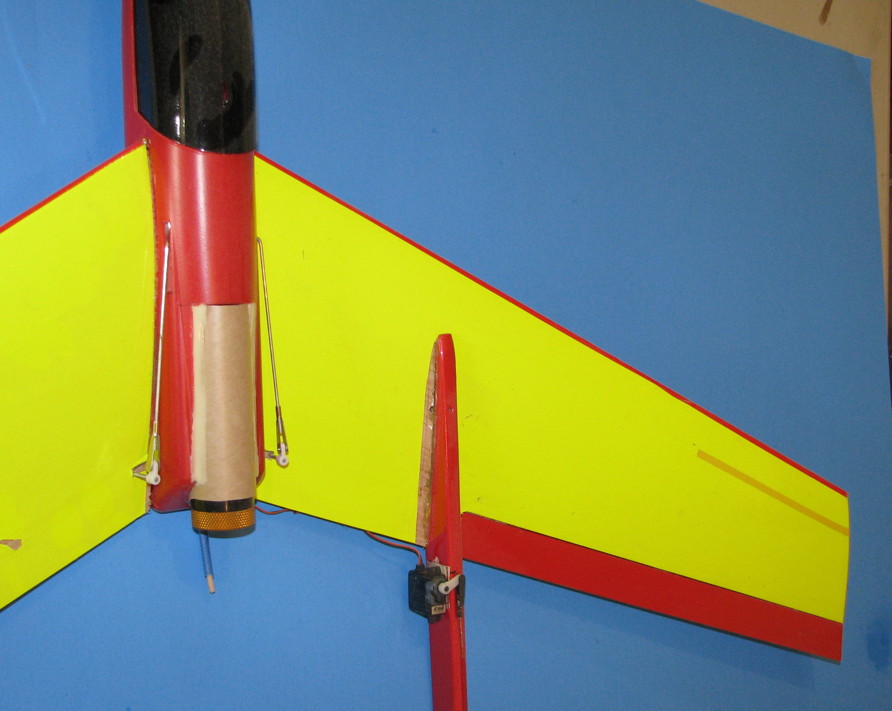

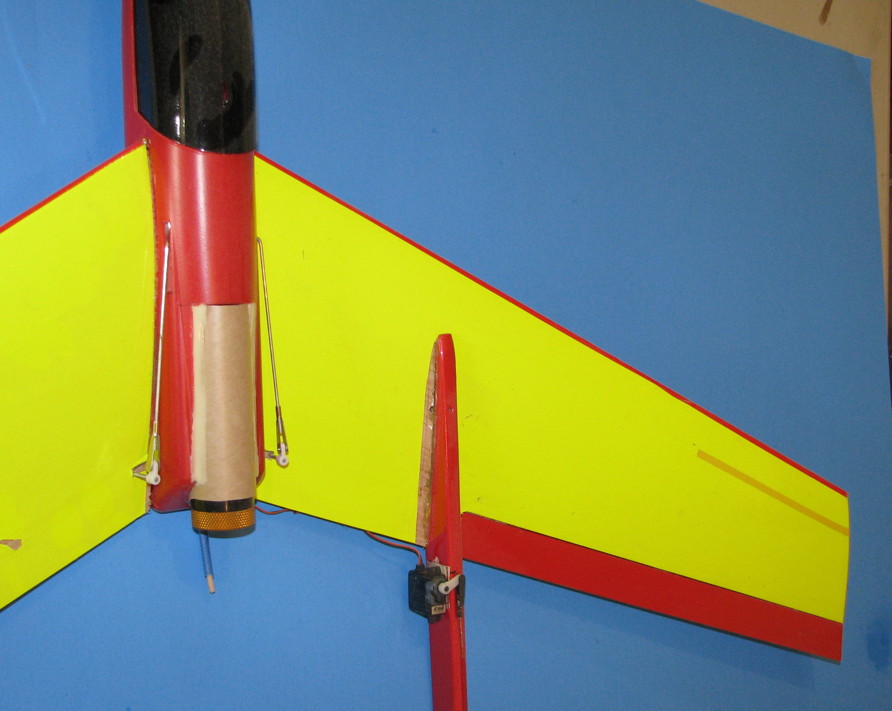

Consider this approach which I recommended to someone else. Indeed the original kit had problems, especially with the elevator pushrod system. Eliminate the "S" curve of the pushrod sleeving, by mounting a small elevator servo (of sufficient torque) directly onto one of the booms. The pushrod sleeve run on TOP of the boom and only curved slightly in one axis. A gentle curve upwards to move the elevator. It worked out well for this model. They added a little bit of solder to the left wingtip to maintain lateral balance (account for the offset mass of the servo on the right boom).

Looks a bit rough as they had a really bad landing that required repair. Wish they'd also added some fiberglass cloth to the balsa boom portions over the wings and 2-3 inches past the the wing TE, as the balsa sure split awfully easily.

Consider this approach which I recommended to someone else. Indeed the original kit had problems, especially with the elevator pushrod system. Eliminate the "S" curve of the pushrod sleeving, by mounting a small elevator servo (of sufficient torque) directly onto one of the booms. The pushrod sleeve run on TOP of the boom and only curved slightly in one axis. A gentle curve upwards to move the elevator. It worked out well for this model. They added a little bit of solder to the left wingtip to maintain lateral balance (account for the offset mass of the servo on the right boom).

Looks a bit rough as they had a really bad landing that required repair. Wish they'd also added some fiberglass cloth to the balsa boom portions over the wings and 2-3 inches past the the wing TE, as the balsa sure split awfully easily.

Last edited:

- Joined

- Jan 27, 2009

- Messages

- 4,490

- Reaction score

- 2,963

Or just put the servo under the stab with a short rod to the elevator and route the servo wire forward. I dont think the ekevon idea will work well on this plane with a large fixed stab. Or remove the tail, put some wingtips for lateral stability and enlarge the ailerons and make it more like a true wing, ala klingberg

Last edited:

- Joined

- Jan 17, 2009

- Messages

- 5,204

- Reaction score

- 1,547

Or just put the servo under the stab with a short rod to the elevator and route the servo wire forward. I dont think the ekevon idea will work well on this plane with a large fixed stab. Or remove the tail, put some wingtips for lateral stability and enlarge the ailerons and make it more like a true wing, ala klingberg

Putting the pitch servo under (or very close to) the stab is an idea used for some planes. It could work with this, but that model is often tail-heavy to begin with, so it would need a LOT more noseweight since the servo would be so far back.

But maybe it would be worth it. But he could try the slight pushrod curve on top of the boom first, to see if it slides well enough so the servo could be mounted at the wing TE. And not all the way at the back of the tail unless the curved pushrod never works out for him.

As for your other idea that he try to convert it into a flying wing..... that's probably above his custom design skills. Indeed I would not even dare try that without making up a crude 50% scale test-glide mock-up first to work out the glide CG, basic elevon settings, etc. But I just do not have good feelings about trying to convert that model, with that wing, and that airfoil, with zero twist, into a flying wing. More like a contest challenge "Try to make this thing fly at all", rather than make the plane fly reasonably well (for what it is, all other things considered). I do not mean that at all as a criticism, just I'm pretty sure if I tried that I'd have a pretty sucky model (I finally converted my old Astro-Blaster to Electric power. It works, and sucks at the same time....

It is a bit funny though, as I had briefly given thought to suggesting he add canards for R/C pitch control. But yet again the same issues of effectively re-designing a plane, which I would not assume he is up to. And the same gut feeling that it would probably fly like crap vs trying to make the conventional tail work

Last edited:

Crawf56

Pig Soooiiieee!!

Thank you gentlemen for looking in on my little thread here. I certainly appreciate your thoughts. So, let me give a little background to my 'madness'.

Over the years of flying my T25 (30 flights?), the elevator performance was never particularly good. Once you get the model up in the air, you are pulling back the elevator "for all its got" to simply prevent a dive. I was already considering some augmentation of the aileron controls (through transmitter programing) to get the ailerons 'helping' the elevator control.

I also fly EDF [Electric Ducted Fan] RC jets, and I have noted the various flying wing models out there:

https://www.motionrc.com/collection...techone-popwing-green-900mm-35-4-wingspan-arf

There is a certain elegance to setting up the T25 as a "flying wing". No changes in weight - simply connect the elevator servo in the nose to the other aileron.

I considered moving the elevator servo to a location for better pushrod performance, but that means adding weight to the tail, on a model that is already tail-heavy. My main interest is flying scale RC models, and in the past 5 years I have changed my focus to "lighter is better" as opposed to "more scale is better". I have seen several RC models greatly improve their flight characteristics by 'keeping it light'.

I am gambling that keeping the T25 light (as possible) and computer transmitter controls (such as Expo) will give acceptable performance.

However, the problem with gambling is that, sometimes you lose......:blush:

EDIT: I will conduct a glide test before launch.

Over the years of flying my T25 (30 flights?), the elevator performance was never particularly good. Once you get the model up in the air, you are pulling back the elevator "for all its got" to simply prevent a dive. I was already considering some augmentation of the aileron controls (through transmitter programing) to get the ailerons 'helping' the elevator control.

I also fly EDF [Electric Ducted Fan] RC jets, and I have noted the various flying wing models out there:

https://www.motionrc.com/collection...techone-popwing-green-900mm-35-4-wingspan-arf

There is a certain elegance to setting up the T25 as a "flying wing". No changes in weight - simply connect the elevator servo in the nose to the other aileron.

I considered moving the elevator servo to a location for better pushrod performance, but that means adding weight to the tail, on a model that is already tail-heavy. My main interest is flying scale RC models, and in the past 5 years I have changed my focus to "lighter is better" as opposed to "more scale is better". I have seen several RC models greatly improve their flight characteristics by 'keeping it light'.

I am gambling that keeping the T25 light (as possible) and computer transmitter controls (such as Expo) will give acceptable performance.

However, the problem with gambling is that, sometimes you lose......:blush:

EDIT: I will conduct a glide test before launch.

Last edited:

Crawf56

Pig Soooiiieee!!

Crawf56

Pig Soooiiieee!!

Crawf56

Pig Soooiiieee!!

My T25 weighs in at 437 grams [15.4 oz], with battery and without motor.

- Joined

- Jan 27, 2009

- Messages

- 4,490

- Reaction score

- 2,963

Are you going to increase aileron suface area or move cg? Normally when you give down flap an airplane with a stab will pitch up, not down which is the opposite of what you want, some will pitch down but hard to know, can you do test glides before committing to a high speed boost?

Crawf56

Pig Soooiiieee!!

Are you going to increase aileron suface area or move cg? Normally when you give down flap an airplane with a stab will pitch up, not down which is the opposite of what you want, some will pitch down but hard to know, can you do test glides before committing to a high speed boost?

I was not planning to make adjustments to the aileron area or CG location. I felt the ailerons were already pretty good size for the model & wing shape.

I too have seen all kinds of pitch movement in aircraft with flaps. My gut feeling is that very subtle changes in the ailerons will affect pitch (because the ailerons are a shorter distance to the CG). I have my transmitter set for 75% expo, in order to have fine control over aileron movement.

There is a field adjacent to where I work (I am an engineer in the steel industry) with tall grass, and I hope to get some toss's on windy days. My thought is that, in a short distance, I can get some feel if the aileron controls are behaving as desired (like a flying wing). For example, simply seeing how the aircraft reacts when I pull back on the stick.

TheTellurian

In space no one can hear you fart

- Joined

- Mar 3, 2009

- Messages

- 339

- Reaction score

- 14

Question? To clear up my confusion does it have an active elevator servo and 1 aileron servo, or is it 2 independent aileron [now elevon] servos with no elevator?

Richard

Richard

JoeG

Well-Known Member

- Joined

- Apr 9, 2009

- Messages

- 773

- Reaction score

- 44

Over the years of flying my T25 (30 flights?), the elevator performance was never particularly good. Once you get the model up in the air, you are pulling back the elevator "for all its got" to simply prevent a dive. I was already considering some augmentation of the aileron controls (through transmitter programing) to get the ailerons 'helping' the elevator control.

I wish you luck in your adventure here and look forward to hearing the results.

I don't want to second guess your reasoning and I have not seen your model fly so all of the following is just speculation based on many years of observing people doing pretty much everything, right and wrong, with R/C airplanes at one time or another including myself. I have also seen people do things that I knew would not work and they worked very well so I will hold my judgment until your experiment is completed.

I concur with frank that almost always deploying flaps in a downward direction on an aircraft with a rear horizontal stabilizer causes the plane to pitch up.

Your description of the gliding part of the flights seems to suggest more of an out of trim situation than a control surface issue. Most rocket gliders I have flown have different trim settings for boost and glide. Even if it's just to allow for the weight of the expended fuel and if you are staging a D12 to a D11 that would cause a significant CG shift. If you are holding full up after boost just to stay level you may have a nose heavy condition after the boost. Particularly if the elevator has little control authority. A tail heavy aircraft will show lots of attitude change with very little throw.

Just thinking out loud. Looking forward to you solving your problem.

- Joined

- Jan 27, 2009

- Messages

- 4,490

- Reaction score

- 2,963

Yes, I hope that it works out, I have my doubts that the pitch control will be sufficient with the horiz stab in place, but your tests will show. You could always remove the horiz stab to get rid of the counter pitching moment, and leave the vertical stabs to maintain lateral stability. At least with this design your motor is not far from the CG so that boost/burnout condition isn't going shift so much.

Frank

Frank

Crawf56

Pig Soooiiieee!!

Question? To clear up my confusion does it have an active elevator servo and 1 aileron servo, or is it 2 independent aileron [now elevon] servos with no elevator?

Richard

Originally, my T25 had one aileron servo and one elevator servo. It now has a servo controlling each aileron, and no elevator-dedicated servo. I am using an "elevon" or "delta" setup on my radio so that the ailerons can be 'both up' or 'both down', like a flying wing.

Some days this seems like a good idea; and other days........ :kill:

Crawf56

Pig Soooiiieee!!

I wish you luck in your adventure here and look forward to hearing the results.

I don't want to second guess your reasoning and I have not seen your model fly so all of the following is just speculation based on many years of observing people doing pretty much everything, right and wrong, with R/C airplanes at one time or another including myself. I have also seen people do things that I knew would not work and they worked very well so I will hold my judgment until your experiment is completed.

I concur with frank that almost always deploying flaps in a downward direction on an aircraft with a rear horizontal stabilizer causes the plane to pitch up.

Your description of the gliding part of the flights seems to suggest more of an out of trim situation than a control surface issue. Most rocket gliders I have flown have different trim settings for boost and glide. Even if it's just to allow for the weight of the expended fuel and if you are staging a D12 to a D11 that would cause a significant CG shift. If you are holding full up after boost just to stay level you may have a nose heavy condition after the boost. Particularly if the elevator has little control authority. A tail heavy aircraft will show lots of attitude change with very little throw.

Just thinking out loud. Looking forward to you solving your problem.

I question my own sanity all the time. I put this idea (elevon control on a T25) for input. I certainly appreciate your comments.

FLAPS - I had/have a Giant Stik that pitches up, and a MiG-15 and a P-47 that pitched down.

However..........in this case, I am not talking about an amount of deflection similar to a flap. I am expecting very small movements to have an affect, similar to landing my Synapse (yellow EDF flying wing in Post #10).

OUT OF TRIM - After no longer being able to find E9-P motors, I was left with D11-P motors, which barely get you high enough to glide back down. In an act of "what the heck", I put a D12-0 booster on, and EUREKA! The T25 flew great. My last 10+ flights were with a booster; almost no control input needed. Which is also why I am reluctant to remove any of the rear rudder & elevator; I fear it will affect launch stability.

The problems with the elevator had more to due with binding and kinks.

Last edited:

Crawf56

Pig Soooiiieee!!

Having gone on and on about the "elevon" control, I must admit that I had already considered mounting a small, powerful servo [Futaba 3114] in the wing near the left boom, in a manner similar to Post #7.

This would allow me to keep the elevator AND individual servo aileron control. Which, in turn, would allow me to set up "flaperons", to slow the T25 just before landing. I need to do some glide tests.......

This would allow me to keep the elevator AND individual servo aileron control. Which, in turn, would allow me to set up "flaperons", to slow the T25 just before landing. I need to do some glide tests.......

TheTellurian

In space no one can hear you fart

- Joined

- Mar 3, 2009

- Messages

- 339

- Reaction score

- 14

Having gone on and on about the "elevon" control, I must admit that I had already considered mounting a small, powerful servo [Futaba 3114] in the wing near the left boom, in a manner similar to Post #7.

This would allow me to keep the elevator AND individual servo aileron control. Which, in turn, would allow me to set up "flaperons", to slow the T25 just before landing. I need to do some glide tests.......

Absolutely do this, I'll explain why:

When flaps or spoilers are used it changes the effective angle of attack of the wing. If the plane glides at 0* wing, 0* stab/elevator and you drop the flaps then the effective AoA [angle of attack] of the wing changes to the opposite of the flap deflection. That is if the flap goes down 20* the wing's AoA goes up some amount dependent on the geometry of the surfaces. So it may now for example be 5* effective wing to 0* elevator. Well thats the same as 0* wing and 5* up elevator and that causes the plane to pitch up. The opposite is true for spoiler [spoileron] where up spoileron causes effective -AoA and a pitch down.

With a dead stab/elevator that will cause the opposite control response to the stick inputs made on the radio!

Actually thats fine if you know and are ready for that to happen. Adjusting the aileron 'droop' could have helped the original configuration lose some of that up elevator problem. That is provided the CG was correct. Saying that another way the original plane may have had too much reflex in the wing which with an elevator at 0* could cause a pitch down in flight.

If you want to fly as a wing only lose the stab but keep the vertical fins other wise add a servo to control the elevator. You could make it a pull/spring and locate the servo anywhere.

Richard

- Joined

- Jan 27, 2009

- Messages

- 4,490

- Reaction score

- 2,963

In addition, I believe the stab location also is impacted by the deflection of the surface, some downwash can influence the stab causing the opposite effect of what you describe. I agree with you he should cut out the stab or put the servo on, he can always fly it to altitude with pitch control then see how the elevons are working once at a safe altitude.

I would definitely run the elevator, I used a small servo on the stab (on the kit built version), I ran it on F and G motors no problem.

I helped the aft CG problem by moving the wing forward, I have a build thread on here somewhere.

I helped the aft CG problem by moving the wing forward, I have a build thread on here somewhere.

Crawf56

Pig Soooiiieee!!

"Intuition is the fastest way to the wrong answer." - Dr. Warton Jemian, founder of Marterials Engineering at Auburn University

Did my glide tests on my T25 with ailerons/elevons only, from a gravel road that was about 5 feet higher than a grassy field. Performance was not bad, but also not acceptable.

Tossing the T25 into a 5 to 10 mph wind, I pulled full up (back) on the control stick. Not a bad glide path, but not the response I had hoped for. Did 3 glides, same response each time. Could not get the aircraft to flare. The glides were good enough for there to be no damage to the T25.

So.....based on my tests, setting up the T25 with 'aileron only' controls is not viable. :kill:

Next step: Installing an elevator servo in the wing. (I do plan to keep separate aileron servos for possible flaperon programming.) :flyingpig:

Did my glide tests on my T25 with ailerons/elevons only, from a gravel road that was about 5 feet higher than a grassy field. Performance was not bad, but also not acceptable.

Tossing the T25 into a 5 to 10 mph wind, I pulled full up (back) on the control stick. Not a bad glide path, but not the response I had hoped for. Did 3 glides, same response each time. Could not get the aircraft to flare. The glides were good enough for there to be no damage to the T25.

So.....based on my tests, setting up the T25 with 'aileron only' controls is not viable. :kill:

Next step: Installing an elevator servo in the wing. (I do plan to keep separate aileron servos for possible flaperon programming.) :flyingpig:

- Joined

- Jan 27, 2009

- Messages

- 4,490

- Reaction score

- 2,963

Matt, I assume you moved the wing back not forward to help CG? Or you moved the motor forward?

I would definitely run the elevator, I used a small servo on the stab (on the kit built version), I ran it on F and G motors no problem.

I helped the aft CG problem by moving the wing forward, I have a build thread on here somewhere.

mr_matt_II

Well-Known Member

- Joined

- Jul 26, 2010

- Messages

- 159

- Reaction score

- 0

Matt, I assume you moved the wing back not forward to help CG? Or you moved the motor forward?

Yes my mistake I moved the wing back. Maybe 1/2 inch IIRC. I also set it up for 32mm motors. It weighed just under 500 grams ready to fly

TheTellurian

In space no one can hear you fart

- Joined

- Mar 3, 2009

- Messages

- 339

- Reaction score

- 14

Sounds like the up elevon flare was neutralized by the negative AoA as predicted.

Richard

Richard

- Joined

- Jan 17, 2009

- Messages

- 5,204

- Reaction score

- 1,547

Pitch trim issues - this is one of those very basic things about R/C RBG's. The elevator trim for boost needs to be less than the elevator trim for glide. Early on, I modified my trasmitter so I could use a toggle swtich to change from using channel 6's lever for the boost trim, to using the elevator trim for glide trim (The transmitter had separate potentiometers for trim, making that possible). With computer transmitters, it's easier to do, no rewiring (well, the computer Tx's I've used, anyway)

So, I have one toggle switch that I use as a Boost or Glide switch. For boost, the elevator trim is set for less elevator than used for glide, also that switch goes to low rate for elevator and "turn" (aileron or rudder depending on the model type). When flipped to glide mode, the elevator trim is higher, and the rates are higher.

Also, perhaps the model needs more up trim than you gave it. That might be simple enough to fix in the computer options in the transmitter (increased servo throw, especially for up), or might require a mechanical fix too such as a longer servo output arm hole location for the elevator pushrod, to get more pushrod travel. Or at the other end, use a shorter distance between the elevator contorl horn hole and the pushrod. I'd go for the longer servo arm, myself, if I wanted more mechanical throw (a bit less torque, but not introduce as much sensitivity for slop/hysterysis in the system as a shorter control horn).

BTW - ALWAYS be on the lookout for hysterysis. Bascially, move elevator up, then release to center. Move elevator down, then release to center. If it does not return to dead center but is biased a bit in the direction it came from, that's a problem. Causes for that are usually either too much friction in the pushrod system, or mechanical "slop" (looseness). Sometimes both. Also long ago, soetimes the servos, but servos these days are better in that regard. If it does not re-center, you need to fix it or it will always be flaky to fly since effectively you have wandering trim. I suspect your original model had that problem. Certainly that is a basic flaw of the T-25/Strato-Blaster to begin with, the original elevator pushrod layout snaking around for too much friction.

Flaperons: Thing about flaperons on the T-25, is you are not going to have real flaperons.

Real flaperons would mean a full-span trailing edge control surface, from root to tip.

On the T-25, only the outer 2/3 of the wing can act like a flaperon, the inner 1/3 is fixed.

My concern is that the model may tend to tip-stall pretty badly. The center 1/3 won't be stalling as soon because it will have less of an angle of attack than the outer "flaperon" portion of the wing once the flaperons are down. But when it comes to a wing stalling you always want the center to stall first, never the tips.

See this post on RC Groups: https://www.rcgroups.com/forums/showthread.php?891870-Tip-Stall-and-Flaperons

The thin airfoil is good for low boost drag, not so good for low speed. So when you try to slow that wing down, if PART of the wing is going to stall first, you want the center of the wing to stall first, tips to stall last. Which is why on a lot of planes that use flaps that are not full-span, the flaps are along the middle of the span, like with the classic P-51, Piper Cub, Cessna, Lear Jet. Or even for aircraft that have "full span" flaps, often the flaps are segmented and the outer flaps do not have as much angle as the inner flaps, so that aerodynically the wing has a twist to it with less angle at the tip than near the center.

But OK, at this point it would be very difficult to try to make the ailerons full span, to cut and rebuild into the wing to make the inner part of the TE hinged and move as one with the outer ailerons. But you can try a few things. One, not use much flap angle. I mean for example if you had the ailerons droop 10 degrees as flaps, I could almost guarantee that model would tip-stall any time you tried any significant roll command. Another trick would be t set up for differential ailerons, so that for aileron control the inboard trailing edge would go UP (Say left aileron when rolling left) perhaps twice as much as the outboard (Say right aileron when rolling left) trailing edge would move down.

Another trick, I recommend for models like this one anyway. Add turbulator strips to the tips.

https://en.wikipedia.org/wiki/Turbulator

For our purposes, it trips the boundary layer early enough for a separation bubble to re-attach and therefore can fly at a higher angle of attack before it stalls

For models like these, the turbulator strip can be vinyl tape about 2 to 3 layers thick, about 1/8 to 3/16" wide. Locate the strip about 25% back from the leading edge. For this model, the last 6" of span. See the photo below.

There have been various models thru the years where I used turbulator strips. Some, to prevent tip-stalling. Others, models that had tip-stall problems and this either cured them or made the tip-stalls a lot less severe.

Having said all that.....I think it'd be best to not do flaperons at all. Stick to the ailerons. Plan out and fly the landing pattern so that you can level it out and keep it wings level for landing. And plan out the landing area so you can undershoot and most importantly overshoot by a long distance. Not try to "spot land", this ain't the kind of model for that.

I mean, you want it to be more forgiving but I really think if you did flaperons on it, it may be LESS forgiving and bite you even worse (tip-stalling)

BTW - in the first photo, that T-25 Centurian has several modifications to it. If has some dihedral. It was modified to use a BT-55 engine mount, to allow using 32mm reloads like F13 and G12. That required doing the aileron pushrods differently. On the outside, then a "Z" bend to go thru slots cut into the blow-molded pod. And actually, that is similar to the original pushrod arrangement that Larry Renger's prototype Estes Strato-Blaster used. It was later changed, against Larry's wishes.

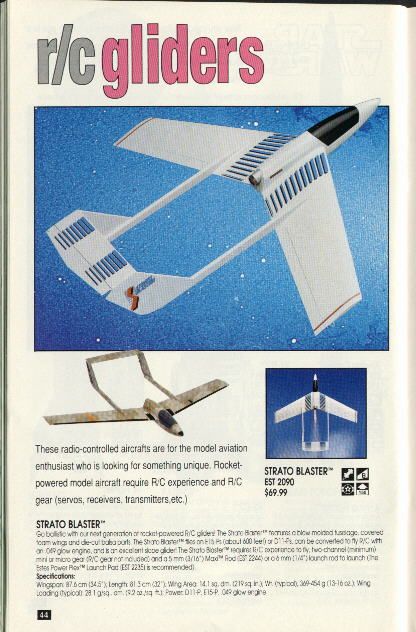

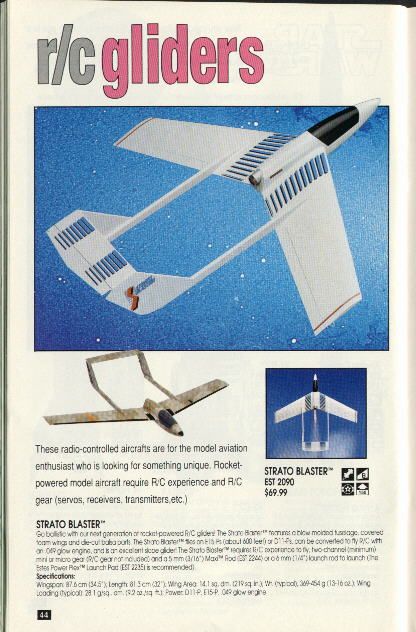

And for those of you who wonder what the "Strato-Blaster" was, well, the T-25 Centurian is the old Stato-Blaster, albeit prefabricated (the Estes R/C R/G kits of the early 1990's all required the foam core wings to be built like model planes of the era, vac-bagged or weights or clamping set-ups to glue the wing skins on and all that).

Link to a kit I sold on eBay years ago, several photos: https://georgesrockets.com/GRP/ebay/2011/StratoBlaster.html

So, I have one toggle switch that I use as a Boost or Glide switch. For boost, the elevator trim is set for less elevator than used for glide, also that switch goes to low rate for elevator and "turn" (aileron or rudder depending on the model type). When flipped to glide mode, the elevator trim is higher, and the rates are higher.

Also, perhaps the model needs more up trim than you gave it. That might be simple enough to fix in the computer options in the transmitter (increased servo throw, especially for up), or might require a mechanical fix too such as a longer servo output arm hole location for the elevator pushrod, to get more pushrod travel. Or at the other end, use a shorter distance between the elevator contorl horn hole and the pushrod. I'd go for the longer servo arm, myself, if I wanted more mechanical throw (a bit less torque, but not introduce as much sensitivity for slop/hysterysis in the system as a shorter control horn).

BTW - ALWAYS be on the lookout for hysterysis. Bascially, move elevator up, then release to center. Move elevator down, then release to center. If it does not return to dead center but is biased a bit in the direction it came from, that's a problem. Causes for that are usually either too much friction in the pushrod system, or mechanical "slop" (looseness). Sometimes both. Also long ago, soetimes the servos, but servos these days are better in that regard. If it does not re-center, you need to fix it or it will always be flaky to fly since effectively you have wandering trim. I suspect your original model had that problem. Certainly that is a basic flaw of the T-25/Strato-Blaster to begin with, the original elevator pushrod layout snaking around for too much friction.

Flaperons: Thing about flaperons on the T-25, is you are not going to have real flaperons.

Real flaperons would mean a full-span trailing edge control surface, from root to tip.

On the T-25, only the outer 2/3 of the wing can act like a flaperon, the inner 1/3 is fixed.

My concern is that the model may tend to tip-stall pretty badly. The center 1/3 won't be stalling as soon because it will have less of an angle of attack than the outer "flaperon" portion of the wing once the flaperons are down. But when it comes to a wing stalling you always want the center to stall first, never the tips.

See this post on RC Groups: https://www.rcgroups.com/forums/showthread.php?891870-Tip-Stall-and-Flaperons

The thin airfoil is good for low boost drag, not so good for low speed. So when you try to slow that wing down, if PART of the wing is going to stall first, you want the center of the wing to stall first, tips to stall last. Which is why on a lot of planes that use flaps that are not full-span, the flaps are along the middle of the span, like with the classic P-51, Piper Cub, Cessna, Lear Jet. Or even for aircraft that have "full span" flaps, often the flaps are segmented and the outer flaps do not have as much angle as the inner flaps, so that aerodynically the wing has a twist to it with less angle at the tip than near the center.

But OK, at this point it would be very difficult to try to make the ailerons full span, to cut and rebuild into the wing to make the inner part of the TE hinged and move as one with the outer ailerons. But you can try a few things. One, not use much flap angle. I mean for example if you had the ailerons droop 10 degrees as flaps, I could almost guarantee that model would tip-stall any time you tried any significant roll command. Another trick would be t set up for differential ailerons, so that for aileron control the inboard trailing edge would go UP (Say left aileron when rolling left) perhaps twice as much as the outboard (Say right aileron when rolling left) trailing edge would move down.

Another trick, I recommend for models like this one anyway. Add turbulator strips to the tips.

https://en.wikipedia.org/wiki/Turbulator

For our purposes, it trips the boundary layer early enough for a separation bubble to re-attach and therefore can fly at a higher angle of attack before it stalls

For models like these, the turbulator strip can be vinyl tape about 2 to 3 layers thick, about 1/8 to 3/16" wide. Locate the strip about 25% back from the leading edge. For this model, the last 6" of span. See the photo below.

There have been various models thru the years where I used turbulator strips. Some, to prevent tip-stalling. Others, models that had tip-stall problems and this either cured them or made the tip-stalls a lot less severe.

Having said all that.....I think it'd be best to not do flaperons at all. Stick to the ailerons. Plan out and fly the landing pattern so that you can level it out and keep it wings level for landing. And plan out the landing area so you can undershoot and most importantly overshoot by a long distance. Not try to "spot land", this ain't the kind of model for that.

I mean, you want it to be more forgiving but I really think if you did flaperons on it, it may be LESS forgiving and bite you even worse (tip-stalling)

BTW - in the first photo, that T-25 Centurian has several modifications to it. If has some dihedral. It was modified to use a BT-55 engine mount, to allow using 32mm reloads like F13 and G12. That required doing the aileron pushrods differently. On the outside, then a "Z" bend to go thru slots cut into the blow-molded pod. And actually, that is similar to the original pushrod arrangement that Larry Renger's prototype Estes Strato-Blaster used. It was later changed, against Larry's wishes.

And for those of you who wonder what the "Strato-Blaster" was, well, the T-25 Centurian is the old Stato-Blaster, albeit prefabricated (the Estes R/C R/G kits of the early 1990's all required the foam core wings to be built like model planes of the era, vac-bagged or weights or clamping set-ups to glue the wing skins on and all that).

Link to a kit I sold on eBay years ago, several photos: https://georgesrockets.com/GRP/ebay/2011/StratoBlaster.html

Last edited:

Link to a kit I sold on eBay years ago, several photos: https://georgesrockets.com/GRP/ebay/2011/StratoBlaster.html

I bought that one and promptly blew the tail off of it. I let it fly too level on a G12 and it built up too much speed. I built a new one but made a lot of changes and molded my own fuse. It flew OK, I never noticed any tip stalling but I did not try to use flaperons. Sorry if I don't understand the gist of this thread but if you tried to fly this without an elevator, I think it would be a short flight. Very short

I have a video of a G12 launch looking aft and it shows my center mounted elevator servo. That stock linkage design was just horrible. You can see the elevator trim change George is talking about pretty clearly. Watch me pushing in the down elevator at about 0:14 seconds in

https://youtu.be/J0qURqEmyog

Last edited:

Similar threads

- Replies

- 6

- Views

- 312

- Replies

- 47

- Views

- 2K