This is a build thread for my L1 rocket. To understand how this came about, read this thread over on Rocketry Online Why keep it Simple?

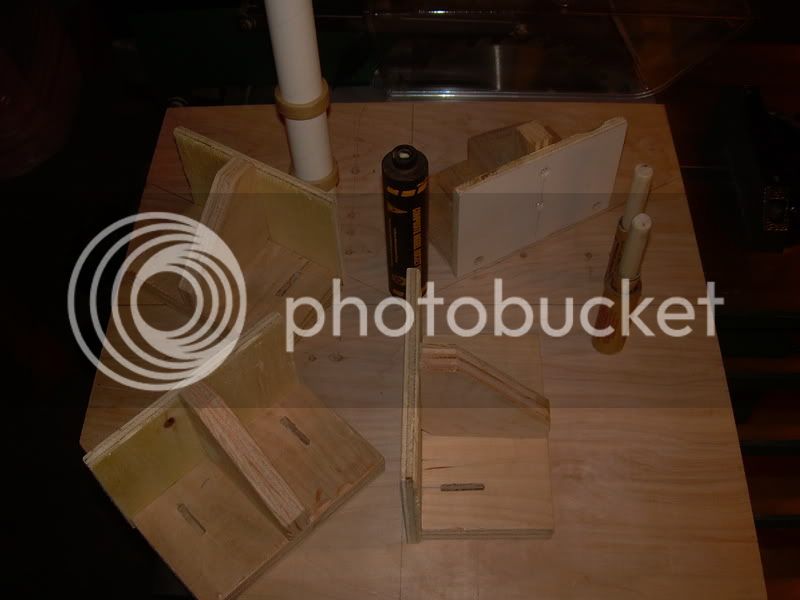

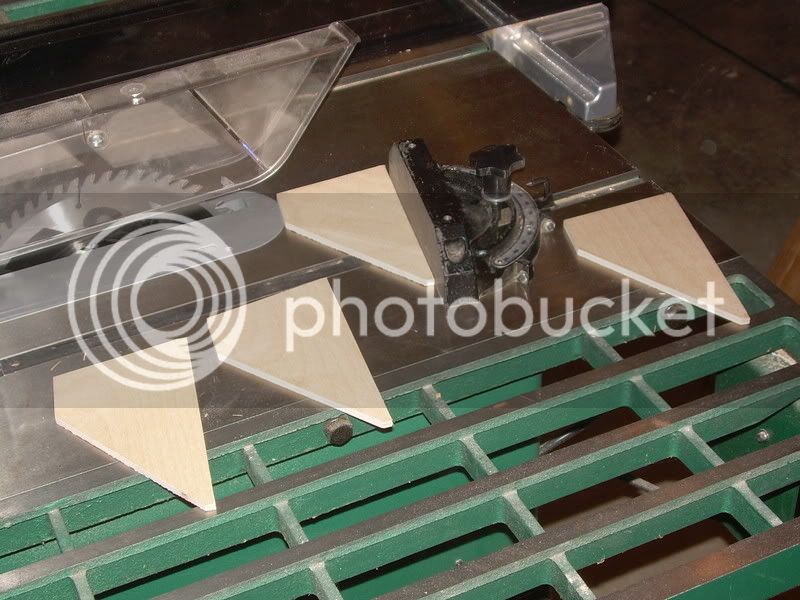

I'm going to call my rocket El Juan It will be a scratch built, 38mm MMT, with dual deployment electronics build out of two 2.25 OD. 2.00 ID tubes I have. It will be about 55 inches high and weigh about 40 oz. I don't have the exact dimensions yet because I haven't built a nosecone for it yet. I do plan on building a 29mm adapter so I can do test launches with G motors in my RMS 40/120 cases.

I expect this will take most of the summer to get it built, test flown, and finally certified. I would like to certifiy with Mike and Ed at Tripoli Central Virginia (#25) and Tripoli East Virginia (#82) perfects, but they don't launch at Culpeper again til Oct. when the crops are in. I'm not sure I can wait quite that long.

Either way, this thread is going to keep popping up from time to time because this isn't going to be a quick build, but it should be fun.

BTW, Yes, I will have pics at as I go along.

I'm going to call my rocket El Juan It will be a scratch built, 38mm MMT, with dual deployment electronics build out of two 2.25 OD. 2.00 ID tubes I have. It will be about 55 inches high and weigh about 40 oz. I don't have the exact dimensions yet because I haven't built a nosecone for it yet. I do plan on building a 29mm adapter so I can do test launches with G motors in my RMS 40/120 cases.

I expect this will take most of the summer to get it built, test flown, and finally certified. I would like to certifiy with Mike and Ed at Tripoli Central Virginia (#25) and Tripoli East Virginia (#82) perfects, but they don't launch at Culpeper again til Oct. when the crops are in. I'm not sure I can wait quite that long.

Either way, this thread is going to keep popping up from time to time because this isn't going to be a quick build, but it should be fun.

BTW, Yes, I will have pics at as I go along.