Nacho

Active Member

Hi,

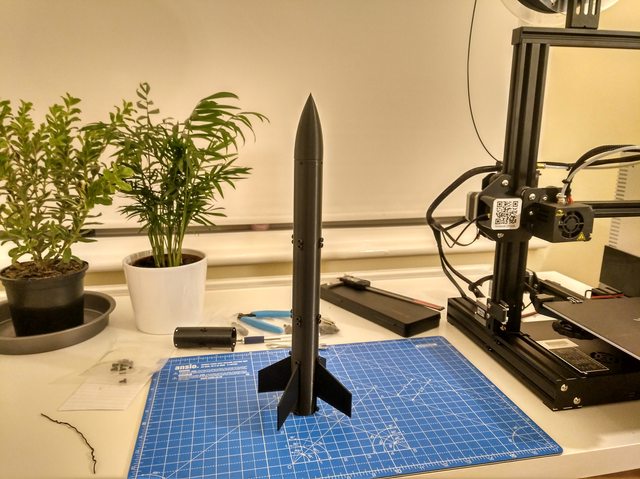

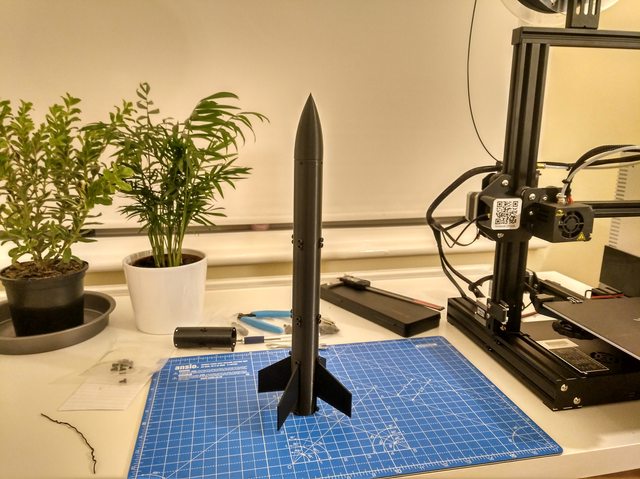

Today I would like to share with you my first ever rocket:

Cormoran MK1

Specs:

About it:

I have been interested in rocketry for a long time. For one reason or the other I really never got into it. I recently purchased a 3D printer and I thought I would give a try at designing my own model rocket!

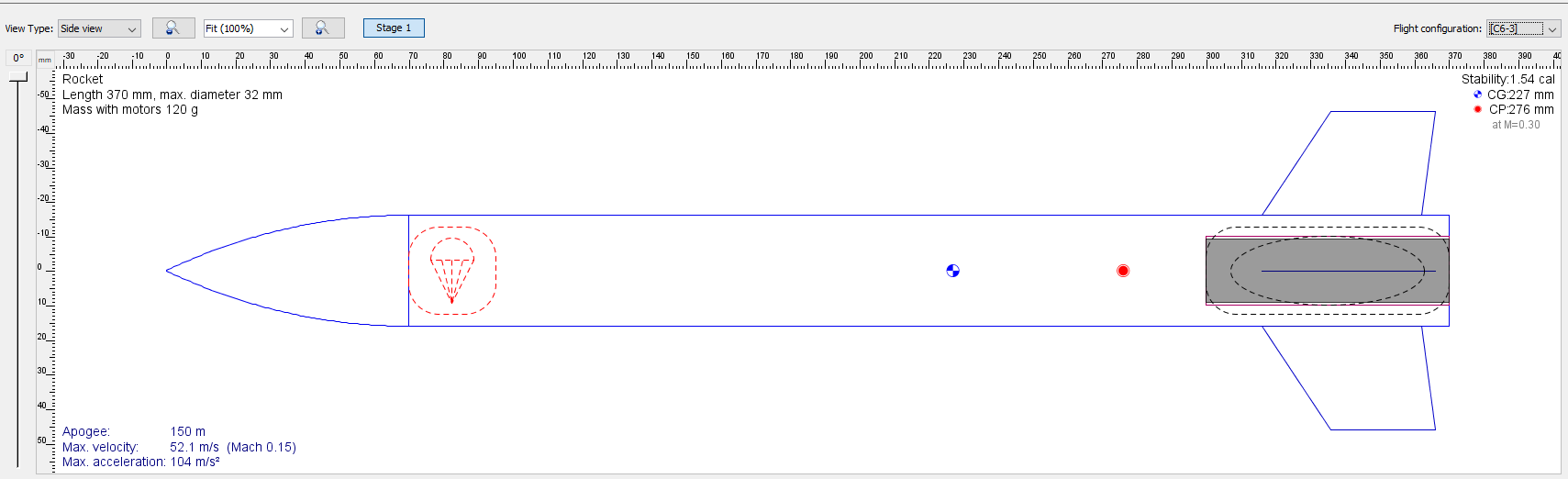

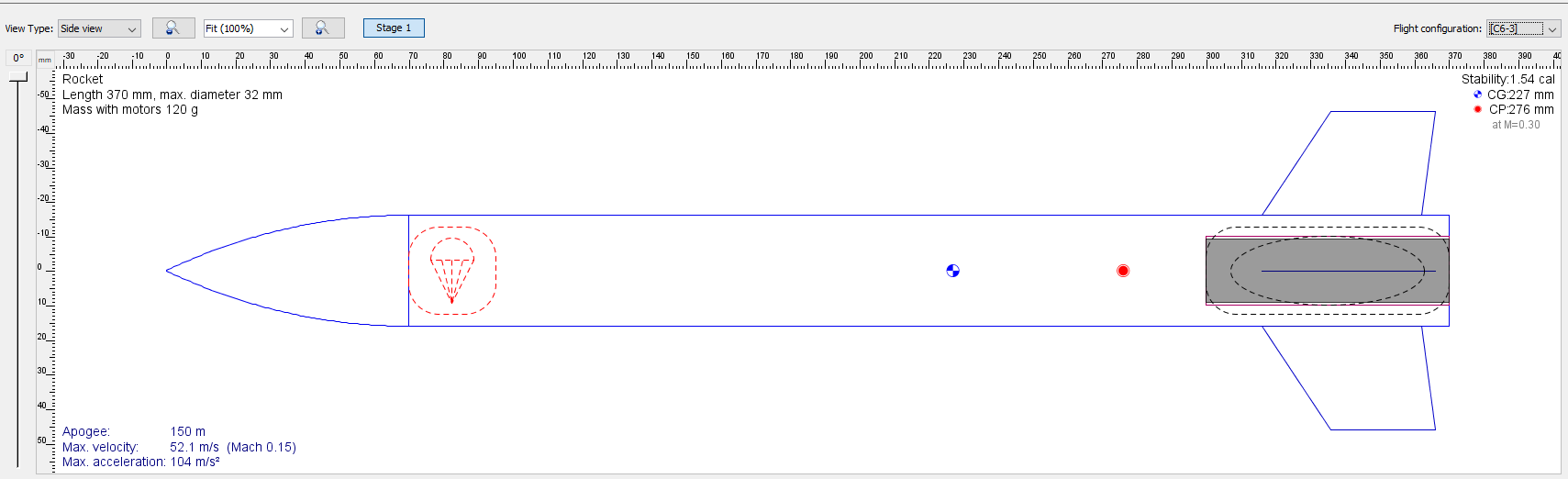

I started by printing some test parts: body tubes, parts with holes, nose cones etc. After having a better idea of the weights and dimensions I jumped to OpenRocket and made the rocket design:

From here, I started designing the actual components using Fusion360. It took me a few weeks to learn the tool and also perfect the measurement of parts that had to fit together.

Up-coming flight:

At this time, the rocket is finished and I am running some simulations to make sure it will fly safely. I am also finishing my chute assembly. This week I will start the works on the launch pad. I am expecting to be ready to go in about 2-3 weeks.

The first flight will be performed using a smaller engine (B4) and the apogee should be at around 50m (~170ft). I think this is a good idea as I have never launched a rocket before .

.

Once I confirm all the parts are working nominally, I will proceed to launch with the C engine.

OpenRocket Files:

You can download the plans for this rocket in the attachments section.

At some point, I would like to release the actual component parts, however, I would prefer to first test this design and make sure it actually flies!

Thanks a lot for reading, wish you clear skies!

~Nacho.

Today I would like to share with you my first ever rocket:

Cormoran MK1

- Length: 370mm

- Body diameter: 32mm

- Propulsion: C6-3

- Mass with motors:124g

- Expected apogee: 150m (~495ft)

- Build material: PLA

About it:

I have been interested in rocketry for a long time. For one reason or the other I really never got into it. I recently purchased a 3D printer and I thought I would give a try at designing my own model rocket!

I started by printing some test parts: body tubes, parts with holes, nose cones etc. After having a better idea of the weights and dimensions I jumped to OpenRocket and made the rocket design:

At this time, the rocket is finished and I am running some simulations to make sure it will fly safely. I am also finishing my chute assembly. This week I will start the works on the launch pad. I am expecting to be ready to go in about 2-3 weeks.

The first flight will be performed using a smaller engine (B4) and the apogee should be at around 50m (~170ft). I think this is a good idea as I have never launched a rocket before

Once I confirm all the parts are working nominally, I will proceed to launch with the C engine.

OpenRocket Files:

You can download the plans for this rocket in the attachments section.

At some point, I would like to release the actual component parts, however, I would prefer to first test this design and make sure it actually flies!

Thanks a lot for reading, wish you clear skies!

~Nacho.